A chemical-stress coupling test device and test method for single-crack rock mass

A test method, technology of cracked rock mass, applied in the direction of measuring device, applying stable tension/pressure to test material strength, scientific instruments, etc., can solve problems such as rock mass damage and affecting test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

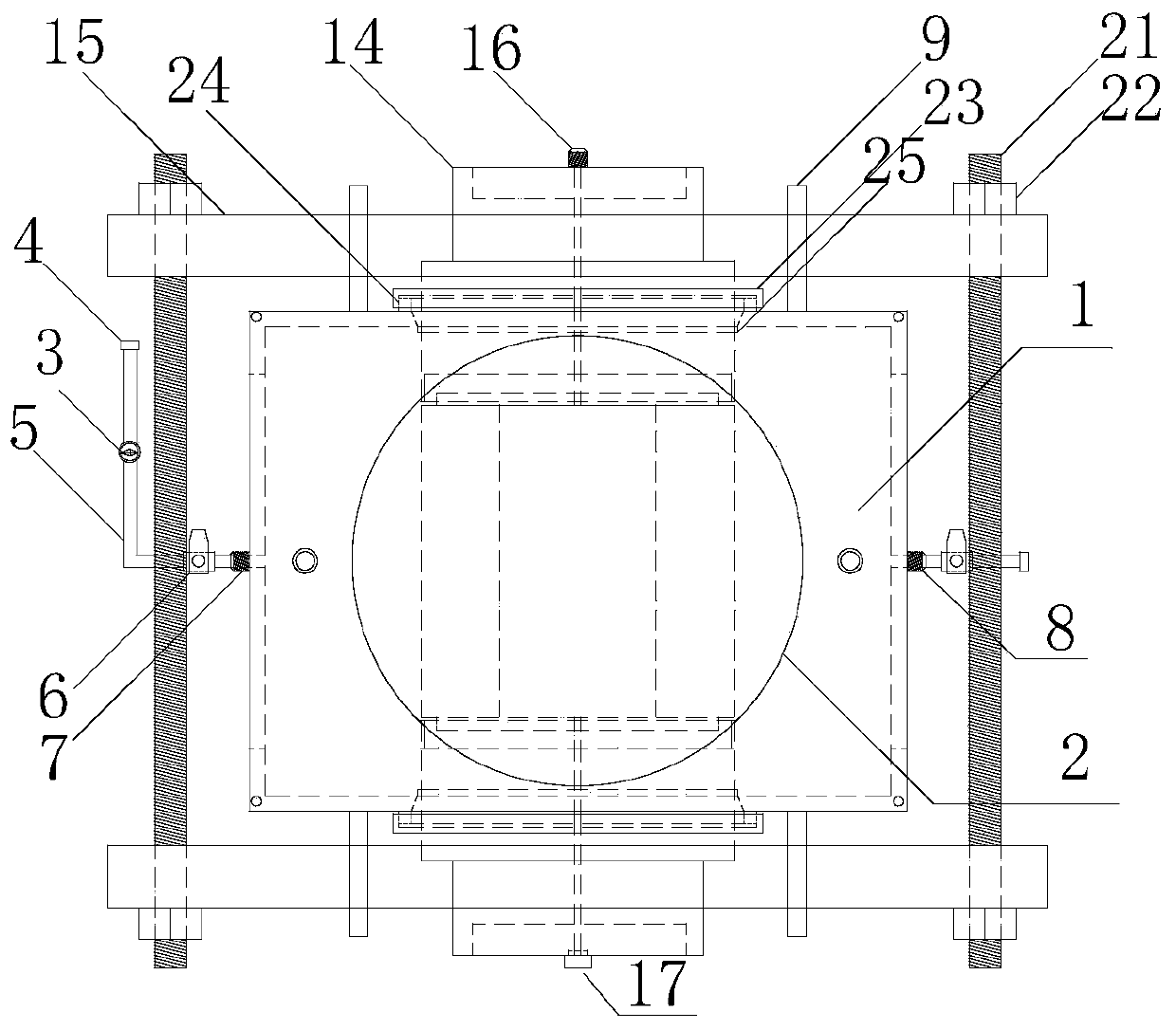

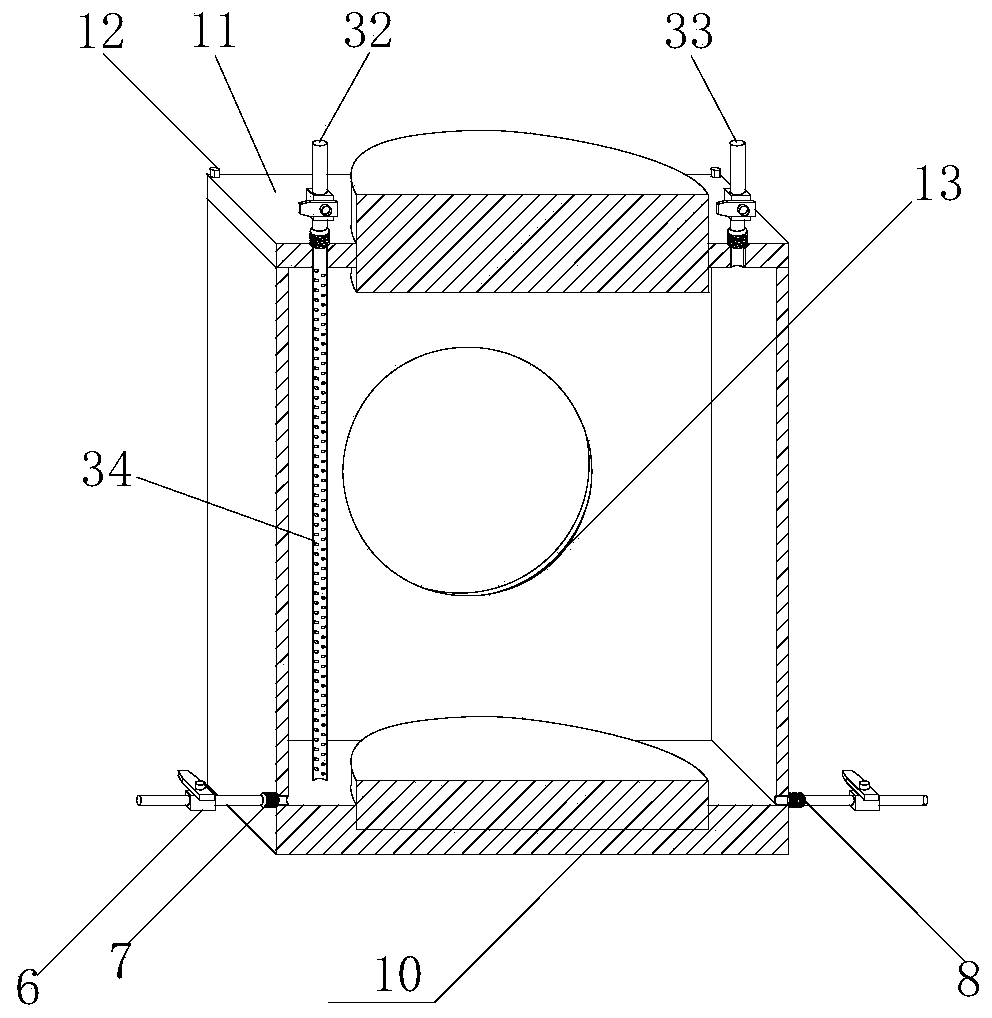

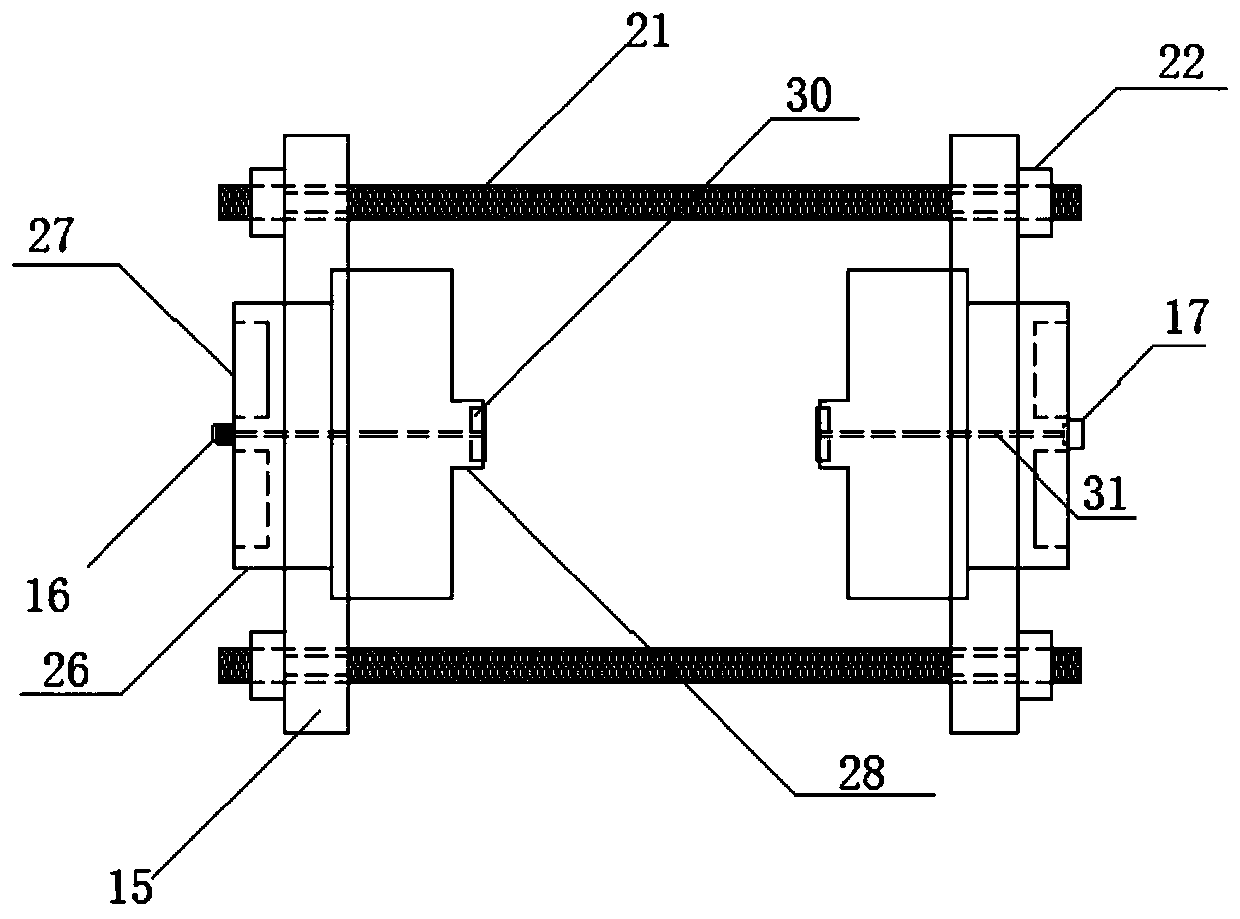

[0035] Such as figure 1 As shown, a single fracture rock mass chemical-stress coupling test device, the device includes a pressure chamber and a water sealing device 14; the pressure chamber includes a pressure chamber shell 1, a pressure chamber top cover 11, a pressure chamber base 10, and The central position of the pressure chamber is provided with a penetrating pressure chamber tapered hole 13, wherein the inner wall of the pressure chamber casing 1 is provided with a corrosion-resistant vent pipe 34, and the center of the pressure chamber top cover 11 is provided with a loading shaft 2, and the pressure chamber casing 1 and the pressure chamber top cover 11 is connected by bolts 12; the water sealing device 14 is fixed by the pressure steel plate 15 and the screw rod 21 through the nut 22 and consolidated with the pressure chamber. The center of the pressure steel plate 15 has a steel plate stepped hole 20, and the pressure steel plate 15 is provided with a stepped column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com