Cable support with automatic umbrella-shaped telescopic legs

An automatic telescopic and cable support technology, applied in the direction of electrical components, can solve the problems of affecting the construction progress and increasing physical labor, and achieve the effect of improving construction efficiency, reducing labor intensity, and being convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

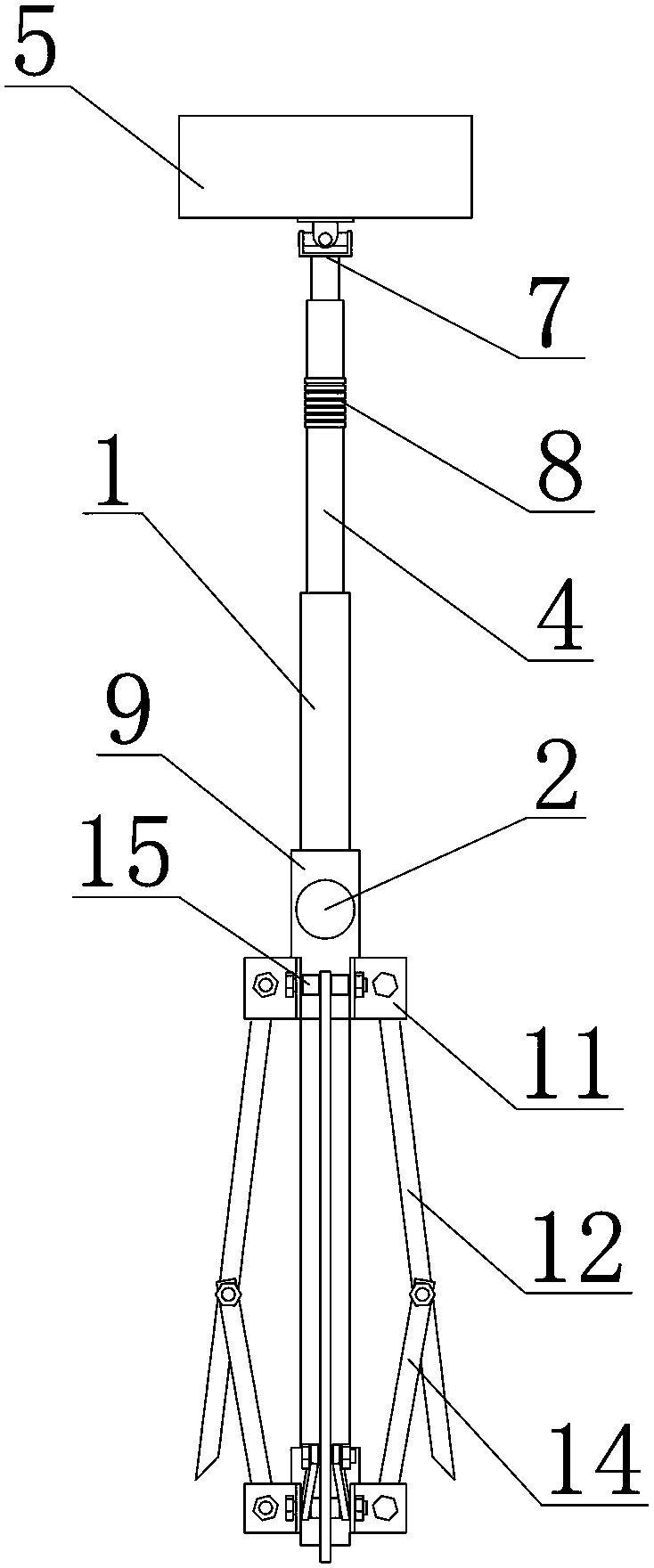

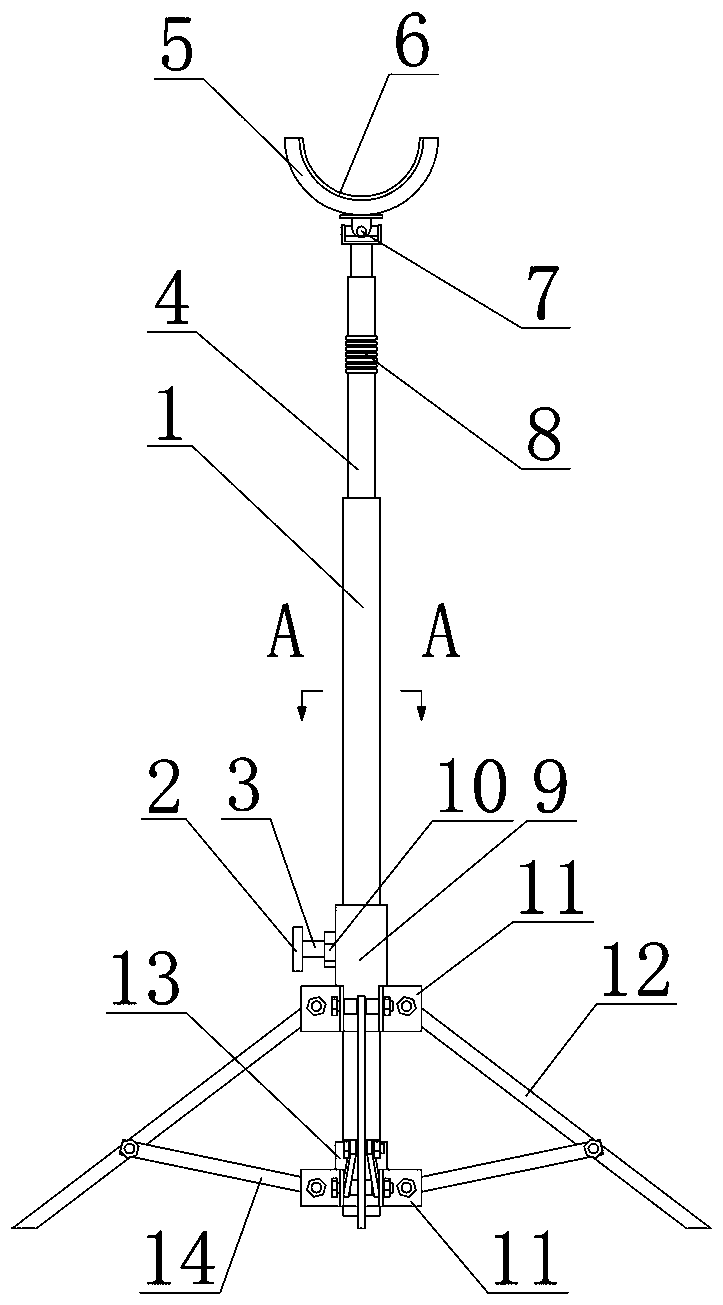

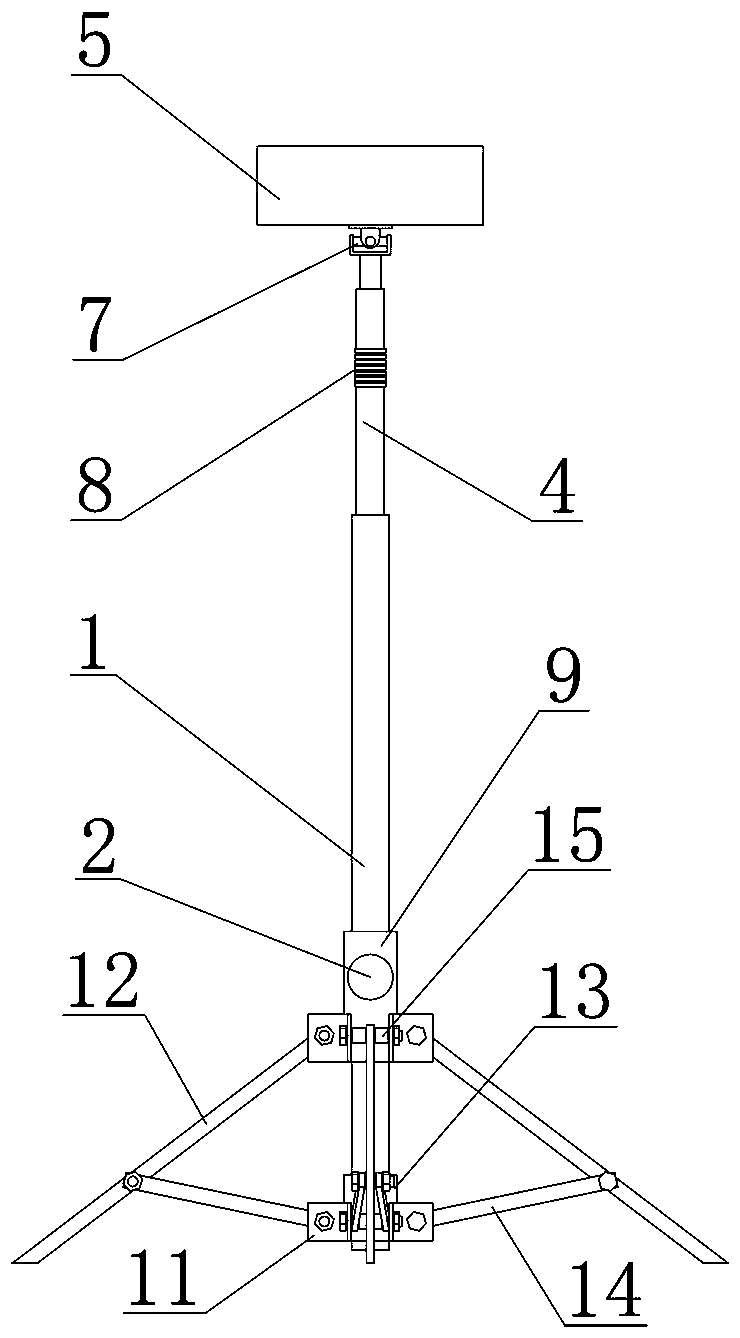

[0025] Such as Figure 1~Figure 5 As shown, a cable bracket with an umbrella-shaped automatic telescopic foot includes a support rod 1, which is arranged in the vertical direction and is a wall thickness structure with a cavity, and also includes an umbrella-shaped automatic telescopic foot arranged at the bottom of the support rod 1. Telescopic foot mechanism, the umbrella-shaped automatic telescopic foot mechanism includes a sliding sleeve 9 and a fixed sleeve 13 that are sequentially sleeved on the bottom of the support rod 1 from top to bottom, and the side walls of the sliding sleeve 9 and the fixed sleeve 13 are Four connecting lugs 11 are respectively welded in four quadrants at the same height, and the connecting lugs 11 are parallel to each other and facing outward, and bolts are passed between two adjacent connecting lugs 11 on the sliding sleeve 9 There is a leg 12, two connecting rods 14 are perforated by bolts between the two adjacent connecting ears 11 on the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com