Evaporative Fuel Treatment Unit

A technology for evaporating fuel and processing device, applied in the field of evaporating fuel processing device, can solve problems such as abnormal gas noise, and achieve the effect of suppressing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

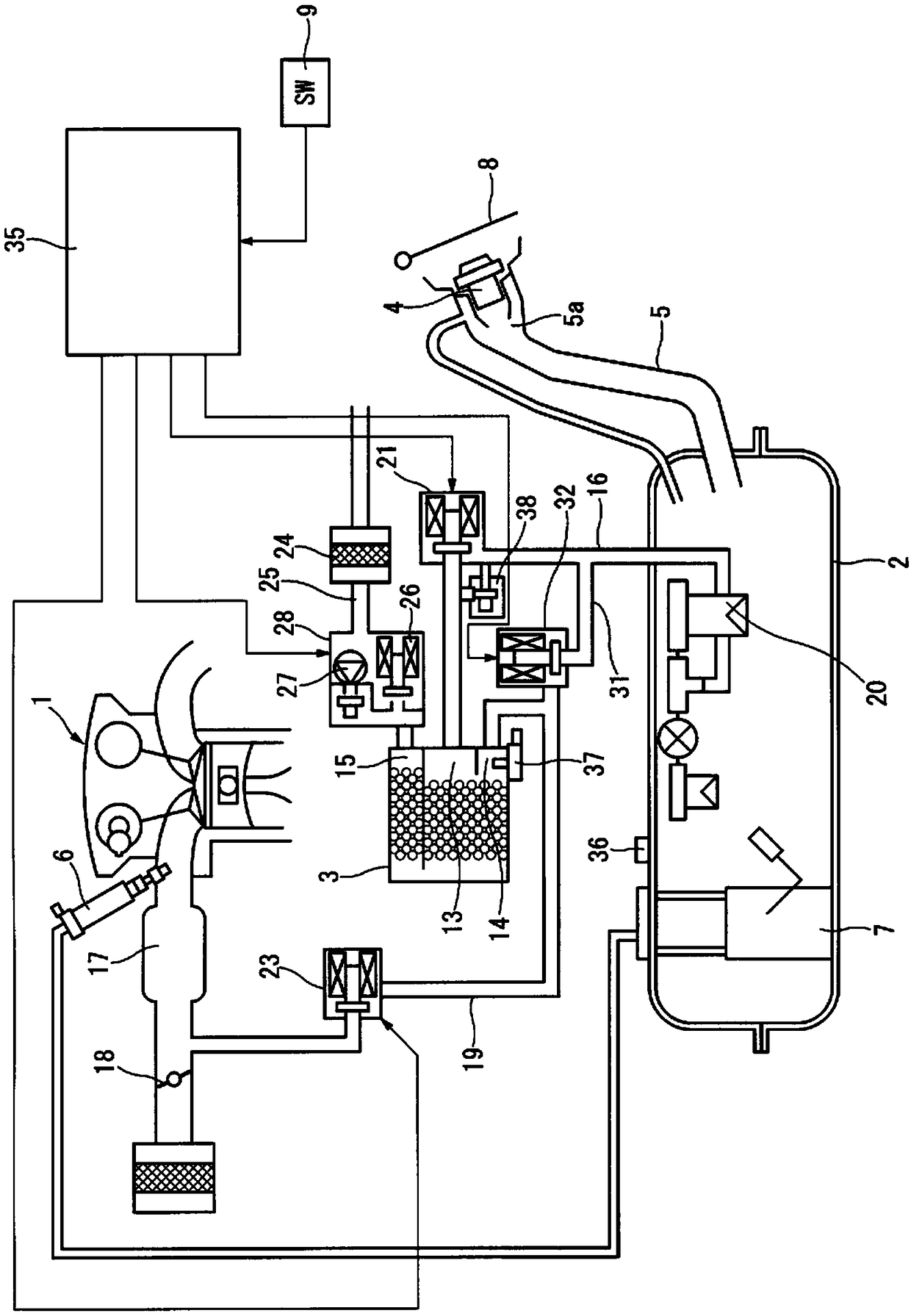

[0021] figure 1 It is an explanatory diagram showing the configuration of an embodiment of the evaporated fuel processing device of the present invention. An internal combustion engine 1 is mounted on a vehicle not shown in the figure, and an airtight fuel tank 2 is installed. In order to process the evaporated fuel generated in the fuel tank 2 during refueling, an evaporated fuel using a canister 3 is installed. Processing device. The above-mentioned fuel tank 2 is provided with a fuel supply pipe portion 5 for detachably attaching and fixing the filler hole cover 4 at the fuel supply port 5a at the top end, and also houses a fuel pump unit 7 for supplying fuel to the fuel injection device 6 of the internal combustion engine 1. Inside the fuel tank 2. The fuel supply port 5 a is covered with an electrically locked fuel cap 8 in order to restrict the opening of the filler cap 4 in a state where the pressure in the fuel tank 2 is high. The fuel cap 8 is unlocked in a state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com