Solvent recovery equipment

A technology for recovering equipment and solvents, which is applied in the field of solvent recovery equipment. It can solve problems such as easy blockage of exhaust pipes, lack of equipment management, and large air volume, and achieve high recovery rate, good condensation effect, and avoid safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

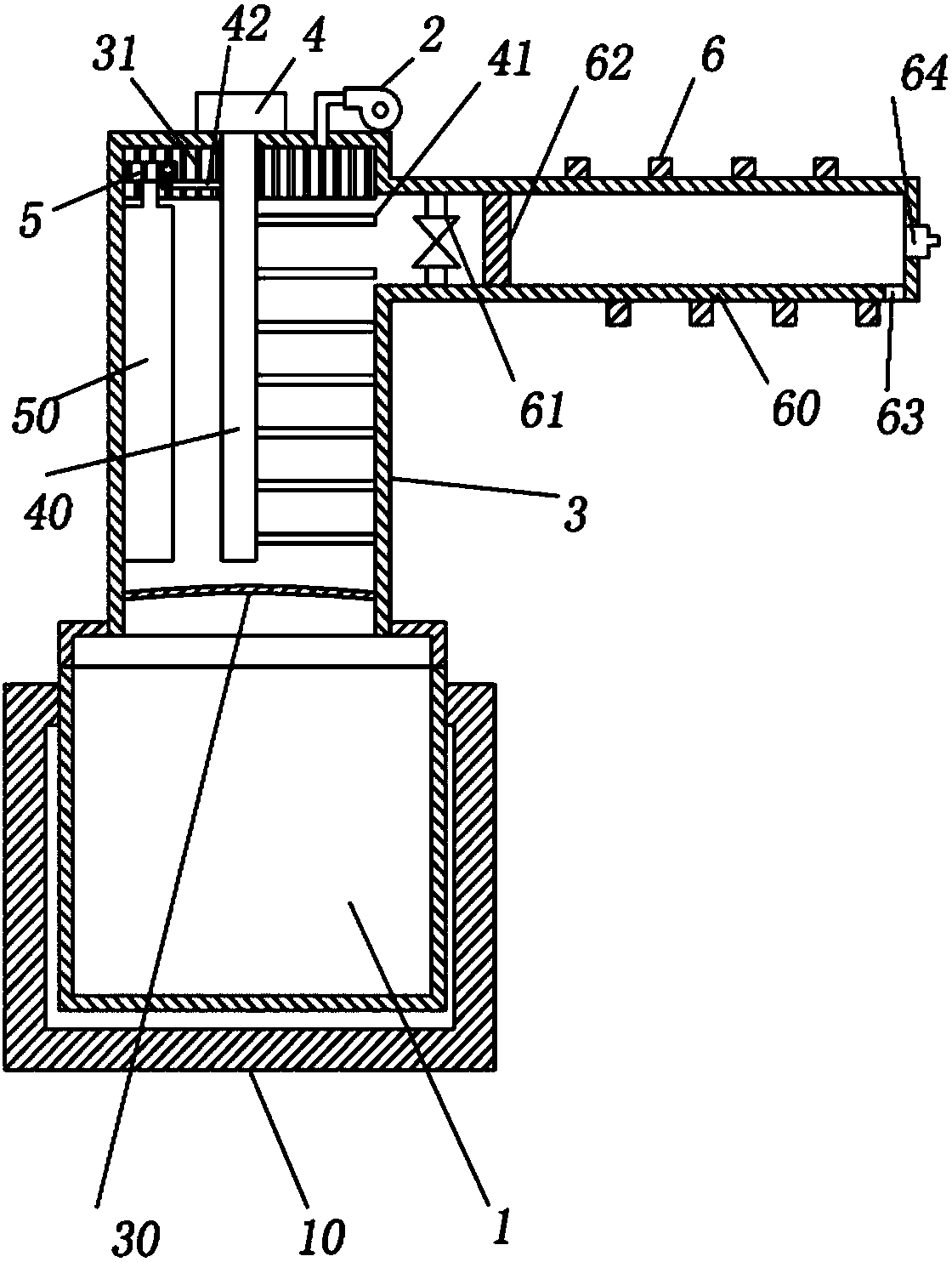

[0022] The reference signs in the drawings of the description include: reaction tank 1, electric heating jacket 10, dust suction fan 2, air exhaust pipe 3, dust suction sheet 30, inner ring gear 31, motor 4, rotating shaft 40, brush 41, support Plate 42, gear 5, roller 50, condensation pipe 6, recovery pipe 60, one-way valve 61, water-absorbing layer 62, liquid outlet 63, transfer port 64.

[0023] The embodiment is basically as attached figure 1 Shown: solvent recovery equipment, including a reaction tank 1 and a heater for heating the reaction tank 1, and also includes a dust removal unit and a recovery unit. The reaction tank 1 comprises a tank body and a tank cover closed on the top of the tank body. The heater is an electric heating jacket 10, and the tank body of the reaction tank 1 is embedded in the heater.

[0024] The dust removal unit includes a dust suction fan 2, an exhaust pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com