Enzyme pretreatment agent used for cotton fiber and treatment method

A technology of pretreatment agent and treatment method, which is applied in the direction of fiber treatment, biochemical fiber treatment, textile material treatment, etc., can solve the problems of insufficient effect, and achieve the effects of less environmental pollution, less damage and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

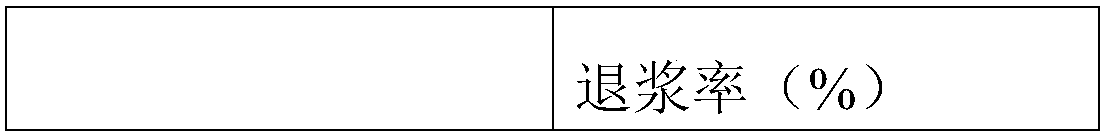

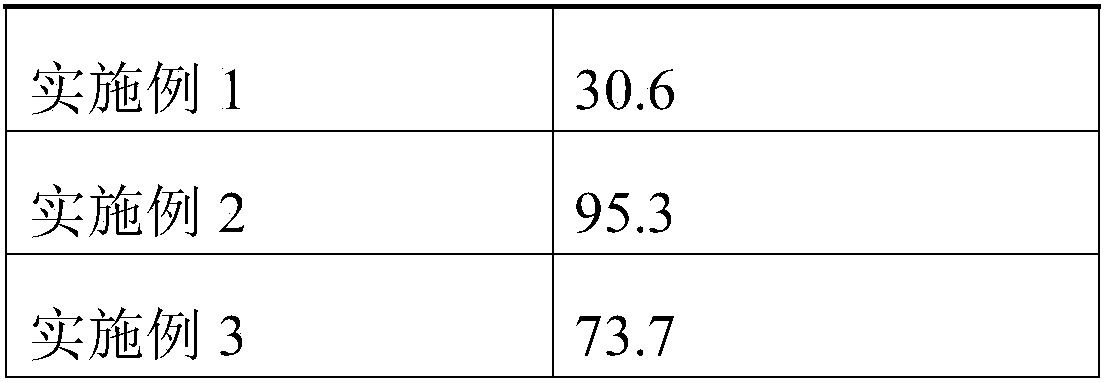

Embodiment 1

[0036] Cotton fabrics are treated with an enzymatic pretreatment including desizing and scouring;

[0037] Described desizing step comprises:

[0038] A1, the pH value of water is adjusted to 3 with the pH regulator;

[0039] A2, with a bath ratio of 1:10, the cotton gray cloth is soaked and squeezed dry and put into the solution prepared in the above step A1;

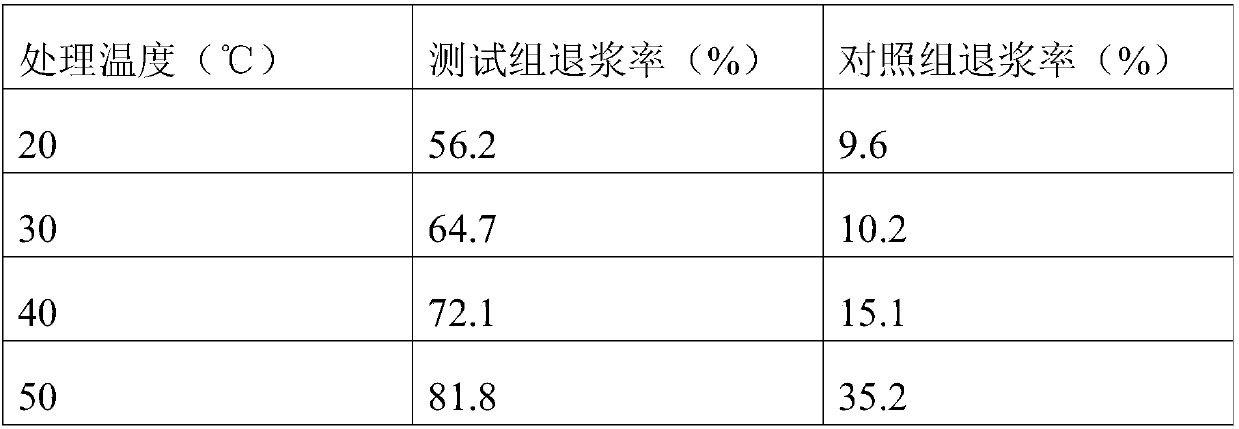

[0040] A3, the temperature is heated to 20°C;

[0041] A4, add component a, and stir evenly, so that in the solution, NATFOCE OL-105 wide temperature amylase 0.1g / L, penetrant JFC 0.25g / L, CaCl 2 1g / L;

[0042] A5, constant temperature for 10 minutes;

[0043] A6, Rinse the cotton fabric twice with hot water at 90°C, then wash with hot water at 50°C, and finally wash fully with cold water.

[0044] The refining steps include:

[0045] B1, adjusting the pH value of water to 3 with the pH regulator;

[0046] B2, with the bath ratio of 1:10, put the desized cotton fabric into the solution prepared in the above ste...

Embodiment 2

[0052] Cotton fabrics are treated with an enzymatic pretreatment including desizing and scouring;

[0053] Described desizing step comprises:

[0054] A1, the pH value of water is adjusted to 6 with the pH regulator;

[0055] A2, with a bath ratio of 1:15, the cotton gray cloth is soaked and squeezed dry and put into the solution prepared in the above step A1;

[0056] A3, the temperature is heated to 60°C;

[0057] A4, add component a, and stir evenly, so that in the solution, NATFOCE OL-105 wide temperature amylase 1g / L, penetrant JFC 1.5g / L, CaCl 2 5g / L;

[0058] A5, constant temperature for 50 minutes;

[0059] A6, Rinse the cotton fabric twice with hot water at 95°C, then wash with hot water at 55°C, and finally wash fully with cold water.

[0060] The refining steps include:

[0061] B1, adjusting the pH value of water to 6 with the pH regulator;

[0062] B2, with the bath ratio of 1:15, put the desized cotton fabric into the solution prepared in the above step B...

Embodiment 3

[0068]Cotton fabrics are treated with an enzymatic pretreatment including desizing and scouring;

[0069] Described desizing step comprises:

[0070] A1, the pH value of water is adjusted to 9 with the pH regulator;

[0071] A2, with the bath ratio of 1:20, the cotton gray cloth is soaked and squeezed and put into the solution prepared in the above step A1;

[0072] A3, the temperature is heated to 90°C;

[0073] A4, add component a, and stir evenly, so that in the solution, NATFOCE OL-105 wide temperature amylase 1.5g / L, penetrant JFC 3g / L, CaCl 2 10g / L;

[0074] A5, constant temperature for 70 minutes;

[0075] A6. Rinse the cotton fabric twice with hot water at 100°C, then wash with hot water at 60°C, and then fully wash with cold water;

[0076] The refining steps include:

[0077] B1, adjusting the pH value of water to 9 with the pH regulator;

[0078] B2, with the bath ratio of 1:20, put the desized cotton fabric into the solution prepared in the above step B1 af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com