Low-resistance flow-equalizing water pipe tee joint

A water pipe, low resistance technology, applied in the direction of pipes, branch lines, pipes/pipe joints/fittings, etc., can solve the problems of high product cost, difficulty in adjusting water flow, large resistance of water pipe tee, and achieve simplified structure and Installation process, broad market application prospects, unobstructed natural mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

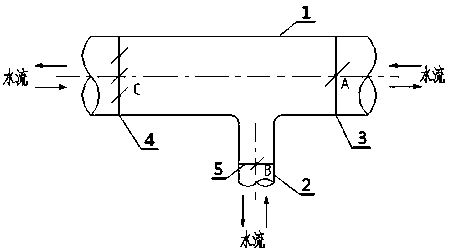

[0012] exist figure 1 Among them, the main body of the water pipe tee commonly used at present is composed of the main pipe 1 and the thinner branch pipe 2 arranged on the surface of the main pipe 1. Regulating valve A 3, regulating valve C 4 and regulating valve B 5 that control water flow are adjusted.

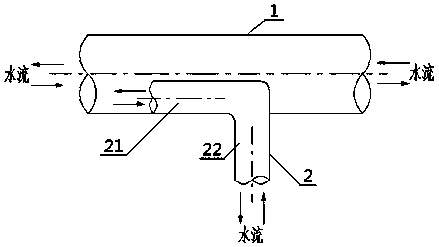

[0013] exist figure 2 Among them, the main body of the low-resistance flow equalizing water pipe tee of the present invention is composed of a main pipe 1 and a thinner branch pipe 2 arranged on the outer surface of the main pipe 1, which is characterized in that the main body of the thinner branch pipe 2 is in an L-shaped natural bending shape. An inner tube 21 fixed on the inner wall of the main tube in parallel with the main tube axis and an outer tube 22 stretched on the outer surface of the main tube 1, wherein the inner diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com