Method for improving temperature measurement precision of thermal infrared imager

An infrared thermal imager and temperature measurement accuracy technology, applied in radiation pyrometry, instruments, measurement devices, etc., can solve problems such as limitations and low temperature measurement accuracy, and achieve the goal of increasing temperature measurement preprocessing and improving temperature measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

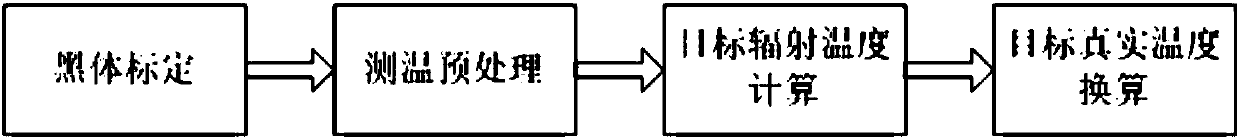

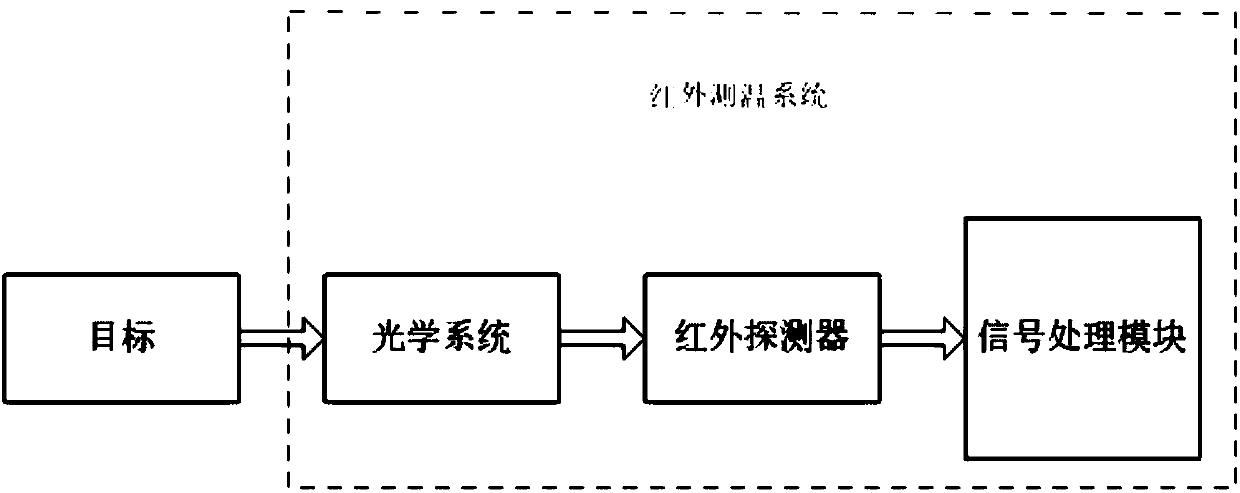

[0021] The principle block diagram of the infrared temperature measurement system of the embodiment of the present invention is shown in the appendix figure 2 , including an optical system, an infrared detector and a signal processing module; the infrared detector obtains the infrared image of the target through the optical system, and the infrared image obtains the real temperature of the target object through the data processing process of the signal processing module. Specific steps are as follows:

[0022] Step 1: Carry out blackbody calibration, and use the difference lookup table method for blackbody calibration:

[0023] Before the thermal imager leaves the factory, use a high-precision black body to calibrate it. The calibration steps are as follows:

[0024] (l) Set the temperature of the black body temperature source as the reference temperature T0, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com