Method for testing tire performance

A testing method and tire technology, which is applied in tire measurement, tire parts, automobile tire testing, etc., can solve the problems of heavy manual statistical workload, inaccurate calculation results, and no process monitoring of tire driving speed, so as to save manpower, Accurate calculation results and avoid inaccurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

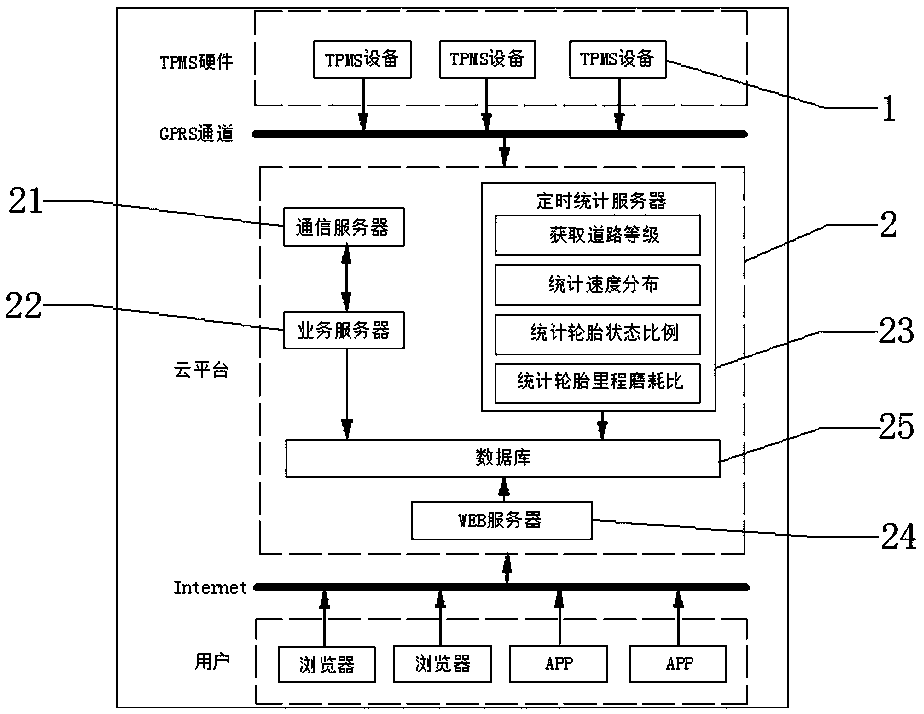

[0032] Such as figure 1 As shown, the hardware and software equipment of the present invention includes: TPMS equipment 1, cloud platform 2 and app, wherein TPMS equipment 1 is mainly responsible for collecting vehicle GPS data and the tire temperature tire pressure data of each tire and uploading to cloud platform 2, and app is mainly responsible for View tire information and upload tire tread depth. Cloud platform 2 is mainly responsible for: (1) Communicating with TPMS device 1, receiving and processing data uploaded by TPMS; (2) Interacting with the app, receiving the tire tread depth uploaded by the app; (3) Providing web services in the form of charts Display tire mileage wear ratio data, tire driving trajectory and other information, customers can view it through computer or WeChat.

[0033] TPMS equipment includes sensors, repeaters a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com