Bituminous pavement structural analysis and increment method based on modulus stress and strain dependence model of pavement materials

A technology for asphalt pavement and pavement materials, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the variety of structural layer modulus test methods and uncertainty of value, can not get satisfactory results, can not be correct Describing nonlinear constitutive relations of asphalt pavement materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Taking an asphalt pavement structure as an example, the incremental method of asphalt pavement structure analysis based on the pavement material modulus stress (strain) dependent model is described. The specific steps are as follows:

[0073] Step 1. Select the asphalt pavement structure form, material type and calculation and analysis system to be analyzed.

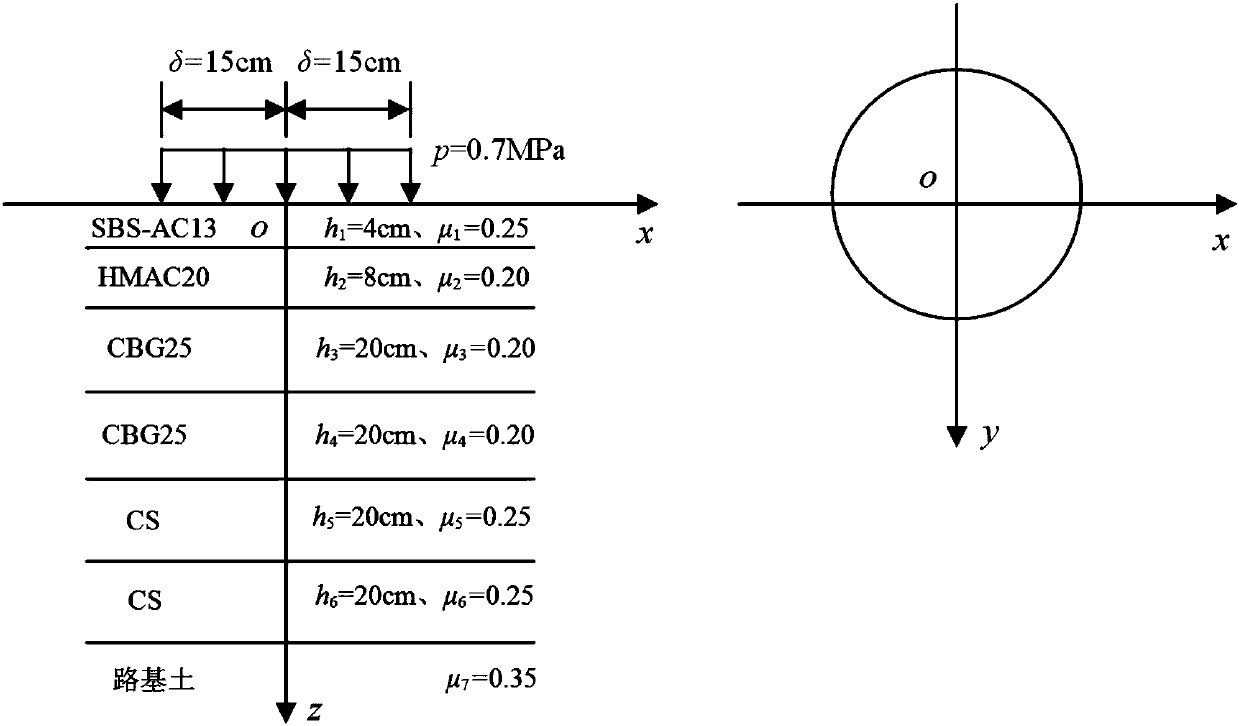

[0074] (1) Choose as figure 1 The long-life asphalt pavement structure with semi-rigid base is shown as the pavement structure to be analyzed. The structure has 7 layers, and the pavement thickness and materials from top to bottom are: 4cm SBS-AC13 asphalt layer, 8cm HMAC20 asphalt layer, 20cm cement stabilized macadam CBG25 semi-rigid base, 20cm cement stabilized macadam CBG25 semi-rigid base, 20cm Cement-stabilized soil CS semi-rigid base, 20cm cement-stabilized soil CS semi-rigid base, road base.

[0075] (2) The Poisson's ratio of SBS-AC13 and cement-stabilized soil CS is 0.25, the Poisson's ratio of HMAC20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com