Method for determining the thickness of the connecting plate of the cutterhead of the full-face rock boring machine

A determination method and connecting plate technology, which are applied in the field of roadheader parts, can solve the problems of reduced utilization rate of full-section rock roadheaders, large deformation of the cutter head connecting plate, large cutter head vibration, etc., so as to improve the equipment utilization rate and reduce the The effect of high vibration and reduced cutter head amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

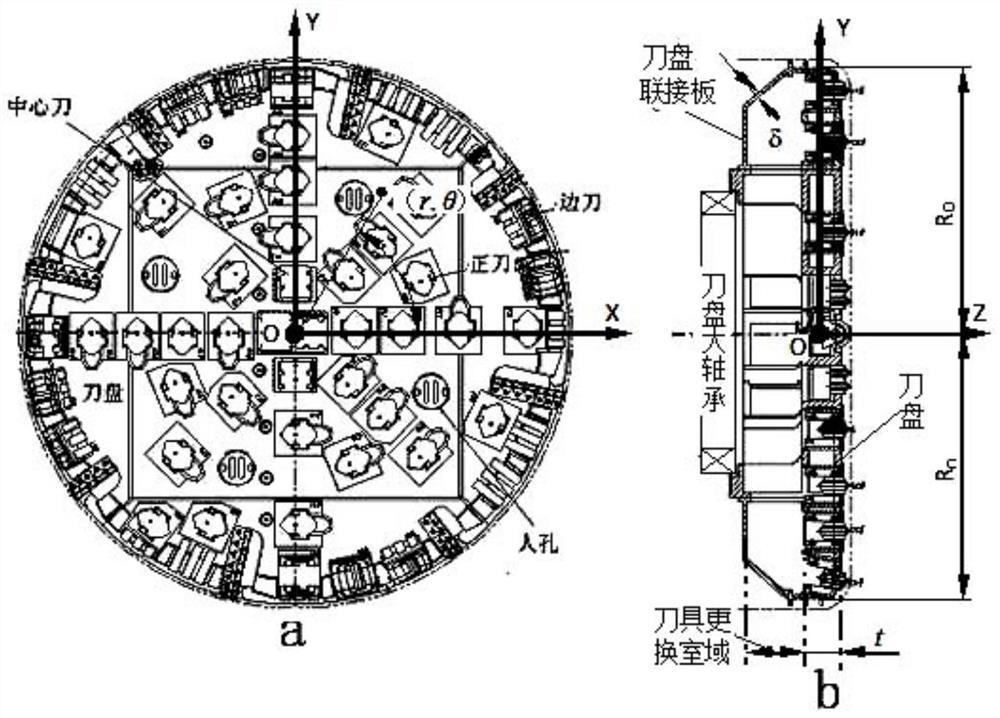

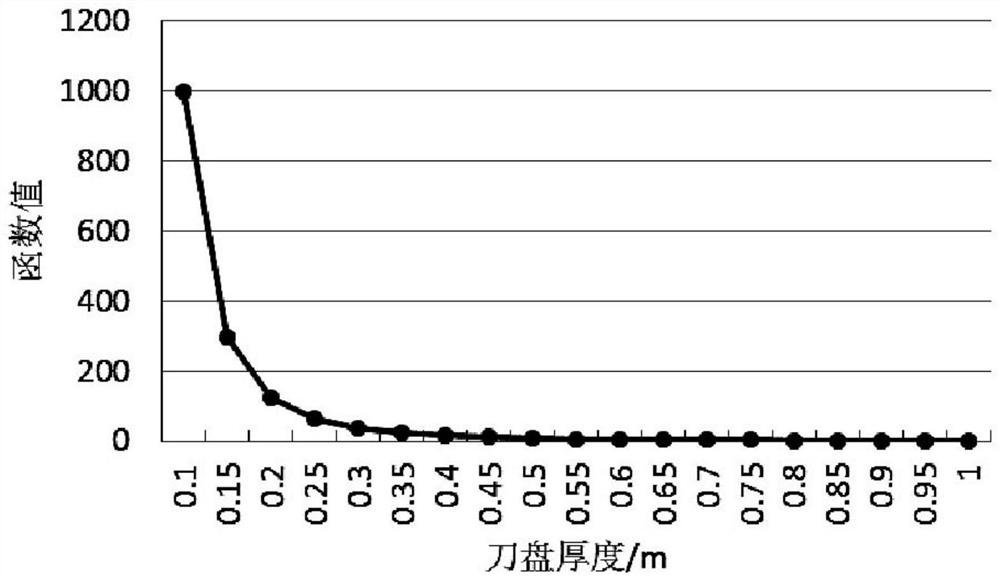

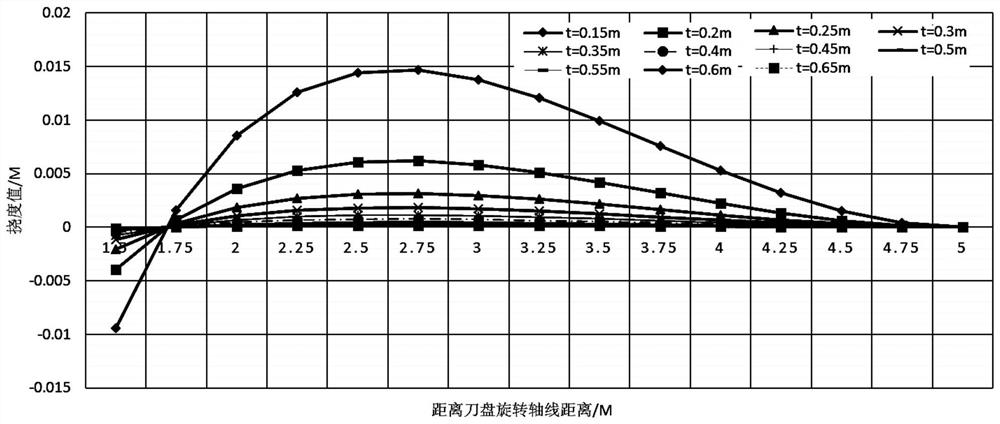

[0108] The material parameter of the cutter head connecting plate of a certain type of full-face rock boring machine is E=2.18×10 11 N / m 2 , μ=0.30; radius of cutter head R 0 is 5m, the surface load on the cutter head q=2.9184×10 5 N / m 2 . Taking the thickness of the cutterhead connecting plate as the series, and the polar diameter as the abscissa, substituting the equation (20) into the deflection curve of the cutterhead connecting plate is as follows: figure 2 , image 3 shown. The thickness of the connecting plate of the original cutter head was 0.15m. After changing it to 0.25m, the amplitude of the cutter head was reduced by about one-third, and the number of disc-shaped hob chipping and cutter ring fractures decreased from 11.3% to 5.1% of the cutter consumption; The utilization rate of full-face rock boring machines increased by nearly 2.4%. It can be seen from this that the deflection value of the cutter head connecting plate is as small as possible and the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com