High-speed magnetic levitation motor with novel air cooling structure

An air-cooled structure, high-speed motor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of unable to cooperate with the installation of the cooling system, to achieve the effect of ensuring safe and stable operation, ensuring control accuracy, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

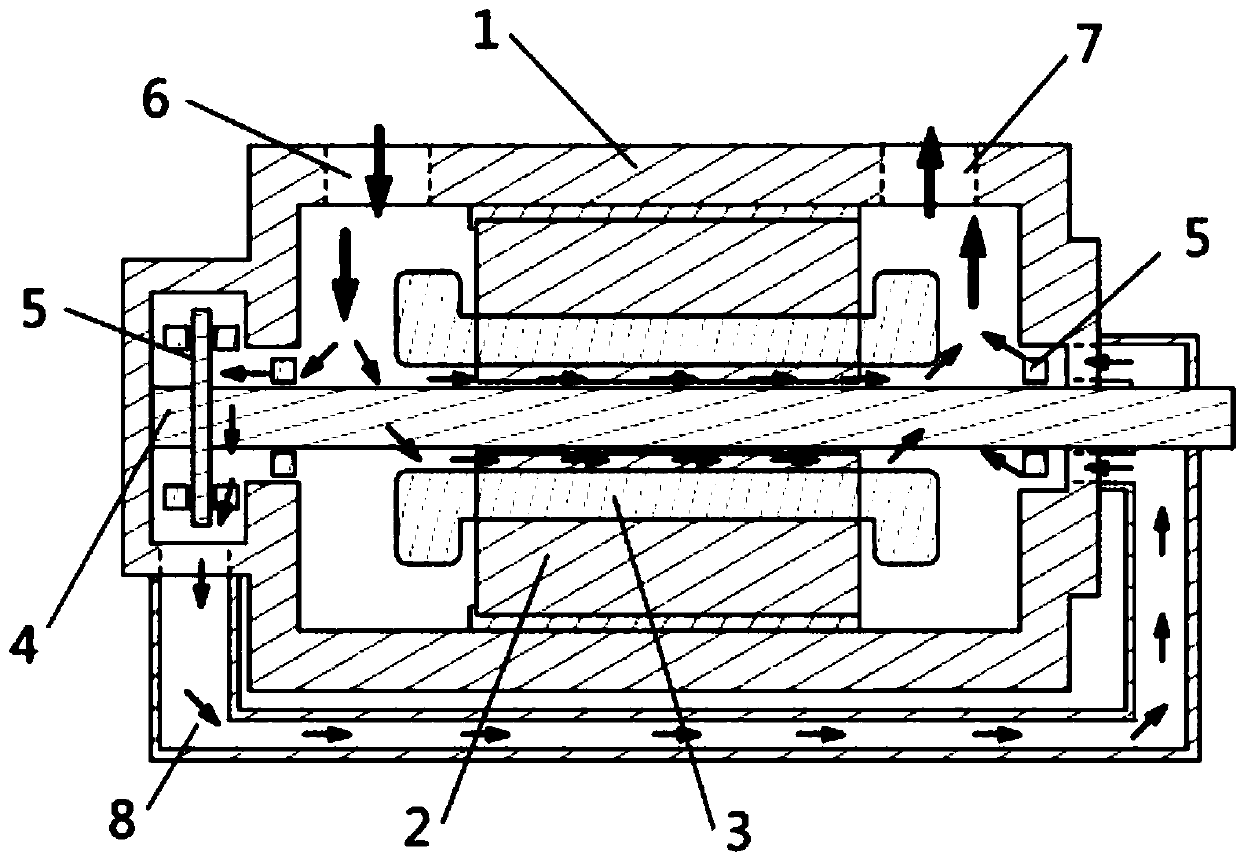

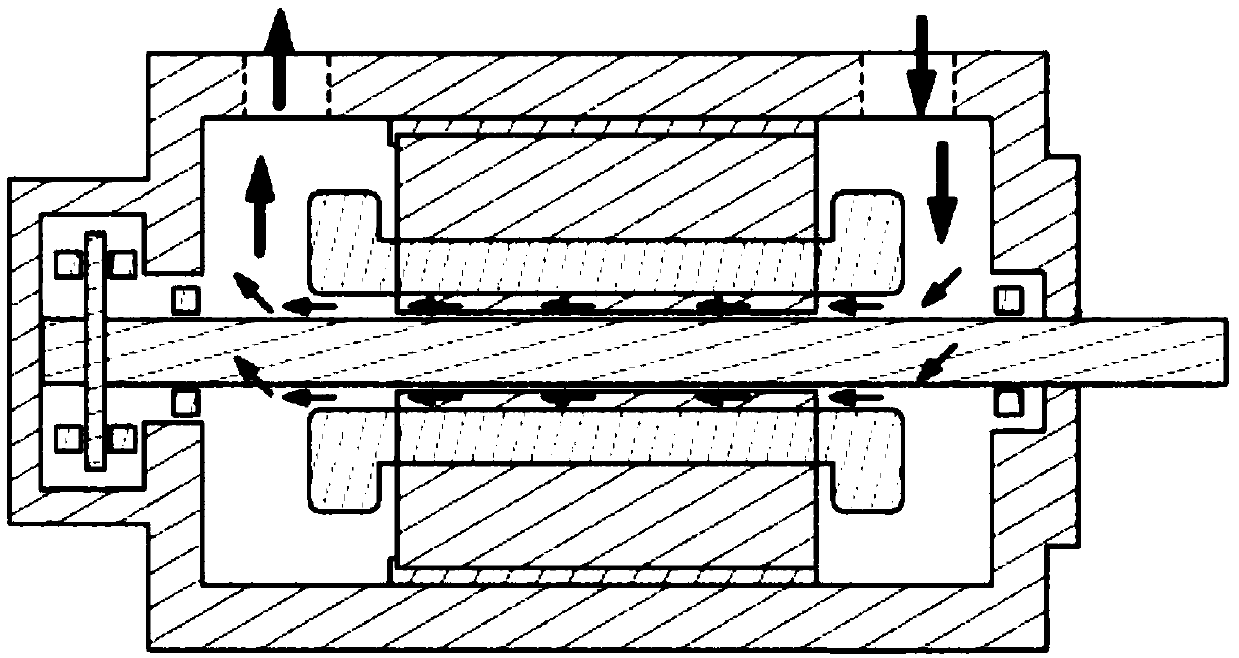

[0028] Such as figure 1 , Figure 5 , Figure 7 As shown, this embodiment provides a magnetic levitation high-speed motor with a new air-cooled structure, including a casing 1, a stator 2, a stator winding 3, a rotor 4, and a magnetic levitation bearing 5, and the casing is designed with an air inlet 6 and an air outlet Tuyere 7. The air-cooled bypass of the present invention has designed ventilation interlayer 8 to realize function on casing 1.

[0029] Such as figure 1 As shown, when the cooling air enters from the air inlet 6, there is a cooling air path for cooling the stator 2, the stator winding 3 and the rotor 4, and another cooling air can also pass through the gap between the magnetic suspension bearing and the rotor, and Along the air-cooled bypass, it flows to the other end of the magnetic suspension bearing for cooling the magnetic suspension bearing. In the present embodiment, the ventilation interlayer 8 and the casing 1 are integrally formed, so that the ...

Embodiment 2

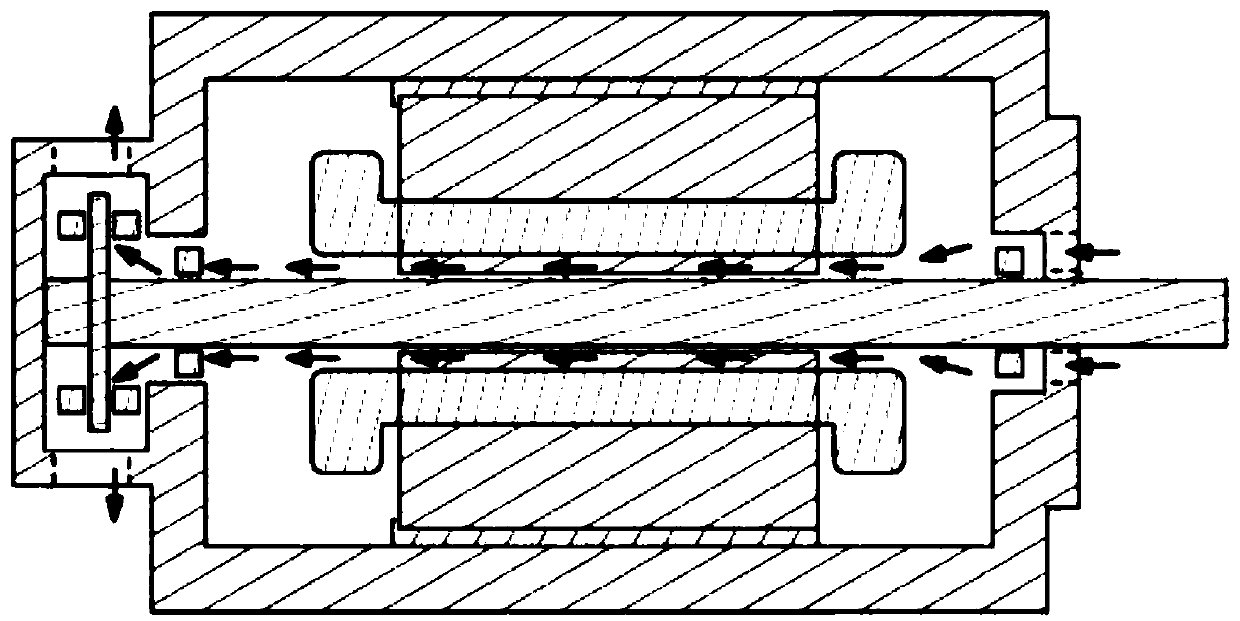

[0032] Such as Figure 6 , Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the structure of the air-cooled bypass is that a wind collecting hood 10 is installed at both ends of the magnetic suspension bearing, and the two wind collecting hoods are connected by a ventilation pipe 11, and the ventilation pipe 11 It is integrated with the casing 1 by welding or tube expansion technology. In this embodiment, there are 8 ventilation tubes 11 for connecting the two wind collecting hoods 10 . In addition, a support plate 12 is welded between the ventilation pipe 11 and the casing 1, and this design is beneficial to enhance the overall stability of the high-speed motor. The working principle of the air-cooled bypass in this embodiment is consistent with that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com