Tires comprising working layers formed from separate wires

A technology for working tire canopy and tires, applied in heavy tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of reducing tire quality and cost, and achieve the effect of light weight and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

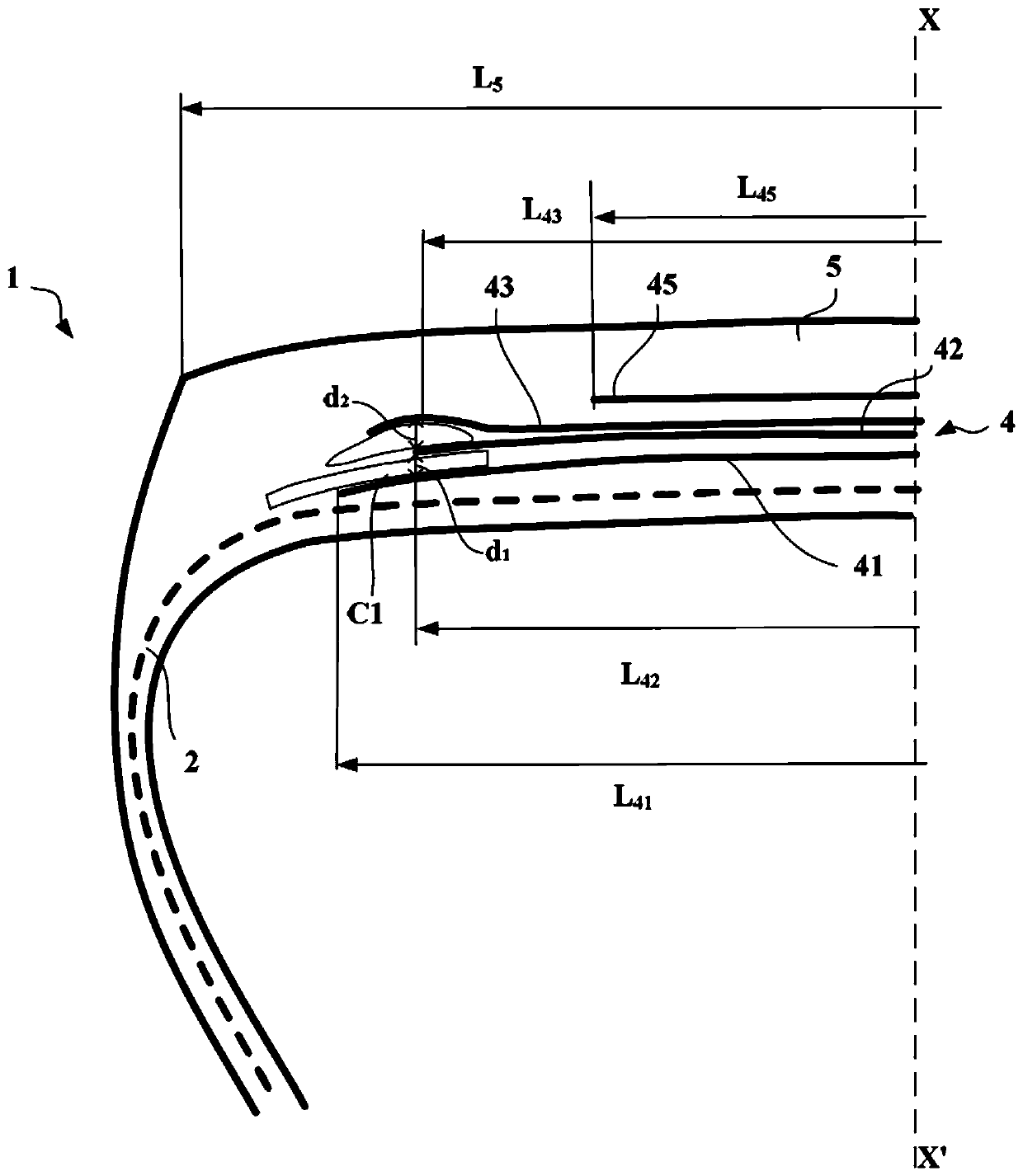

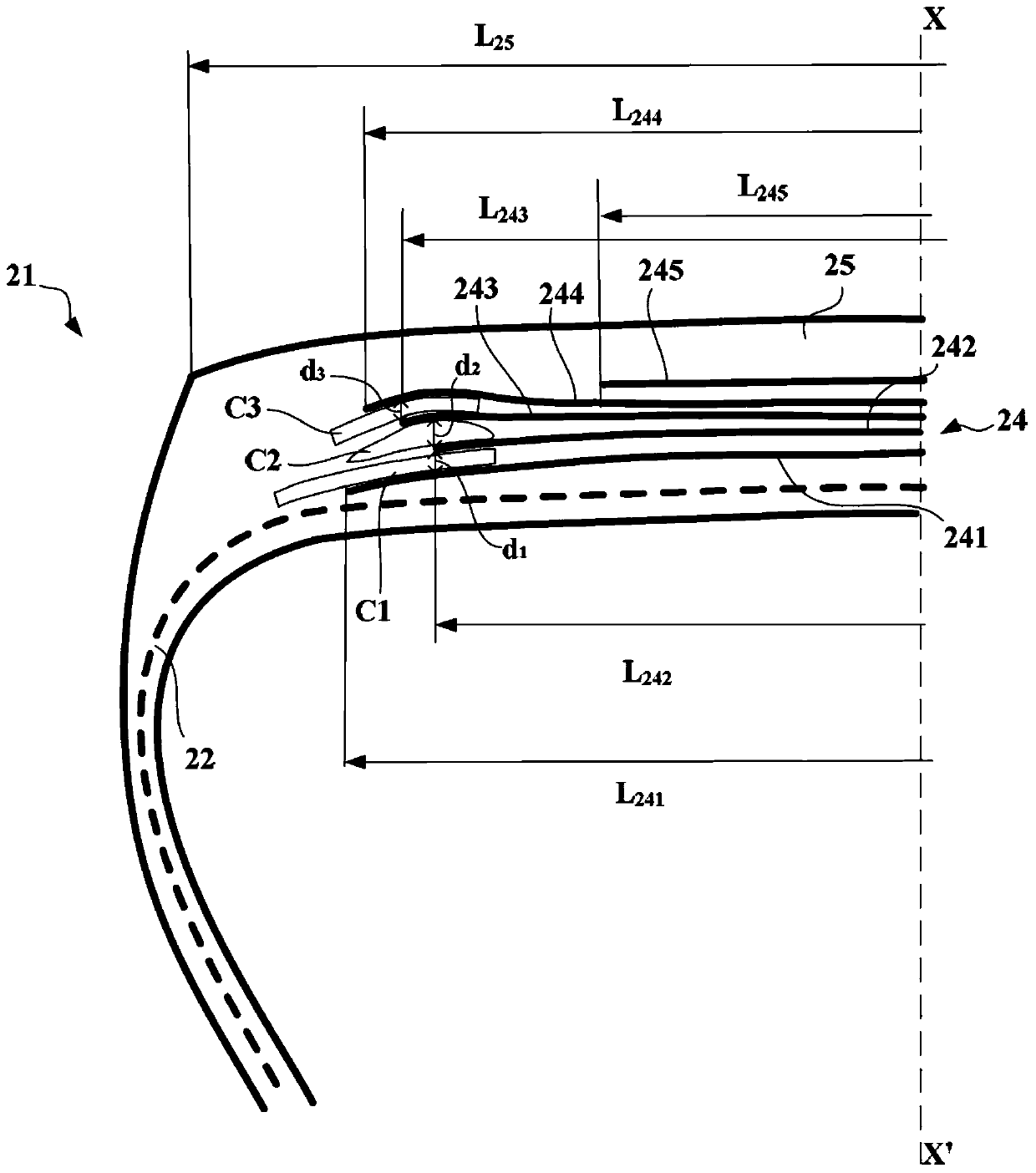

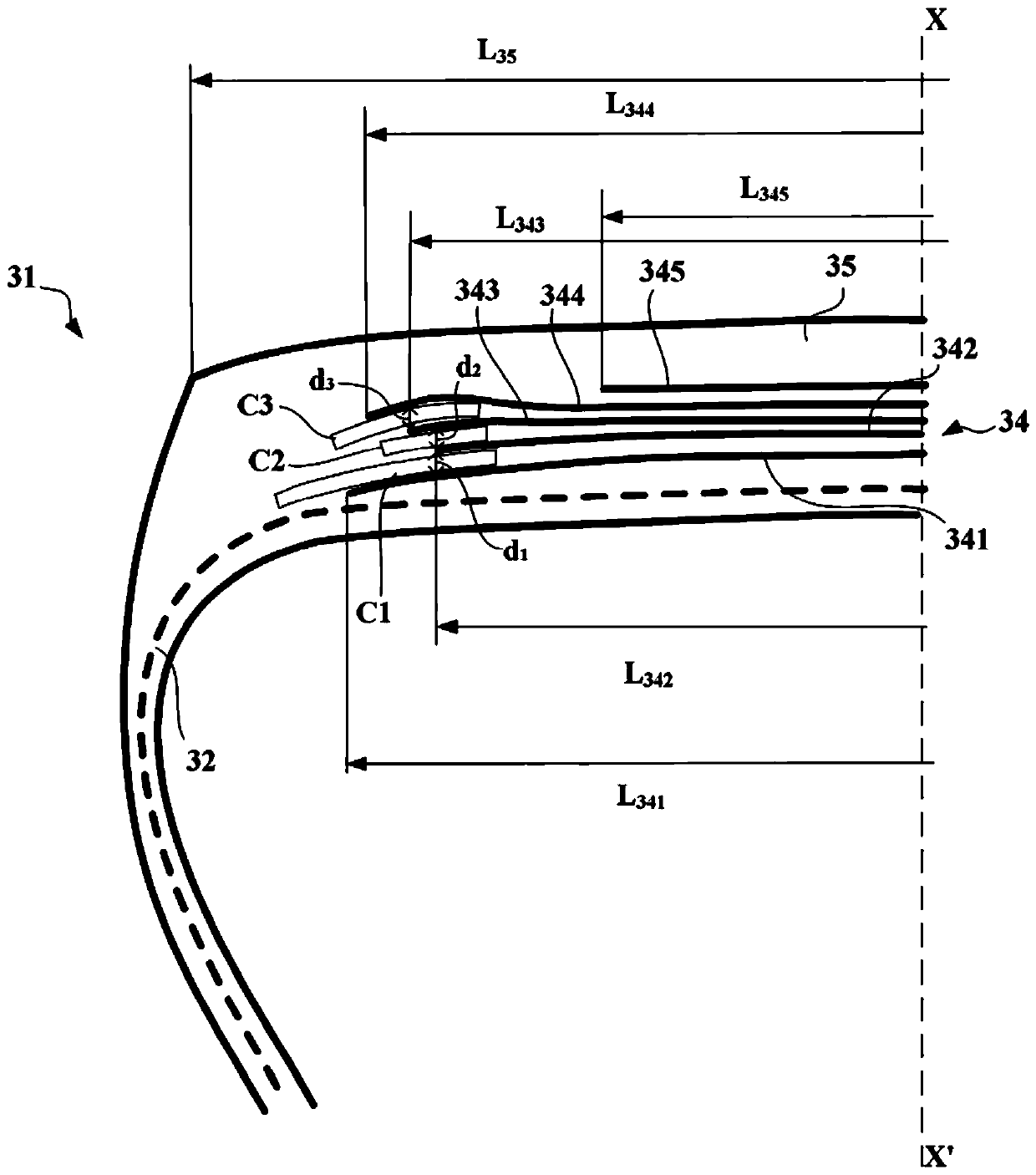

[0131] To simplify understanding, the drawings are not drawn to scale. The drawings only show a half view of the tire, which extends symmetrically with respect to the axis XX', which represents the circumferential median plane or equatorial plane of the tire.

[0132] In the figure, the tire 1-41 of size 385 / 55R 22.5 has an aspect ratio H / S equal to 0.55, H is the height of the tire 1-41 on its mounting rim, and S is the maximum axial width. The tire 1-41 includes radial carcass reinforcements 2-42 anchored in two beads (not shown in the figure). The carcass reinforcement 2-42 is formed of a single layer of metal cords. They further include treads 5–45.

[0133] in figure 1 According to the present invention, the carcass reinforcement 2 is hooped by the crown reinforcement 4, which is formed from the inside to the outside in the radial direction as follows:

[0134] -A first working layer 41 formed of metal wires oriented at an angle equal to -18°,

[0135] -A second working layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com