Pure copper toughened biomedical titanium-based amorphous matrix composite material and preparation method thereof

A technology of biomedical and composite materials, applied in the chemical and medical fields, can solve the problems of low strength, difficult sintering, poor plasticity, etc., and achieve the effect of high strength, high toughness, and low modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

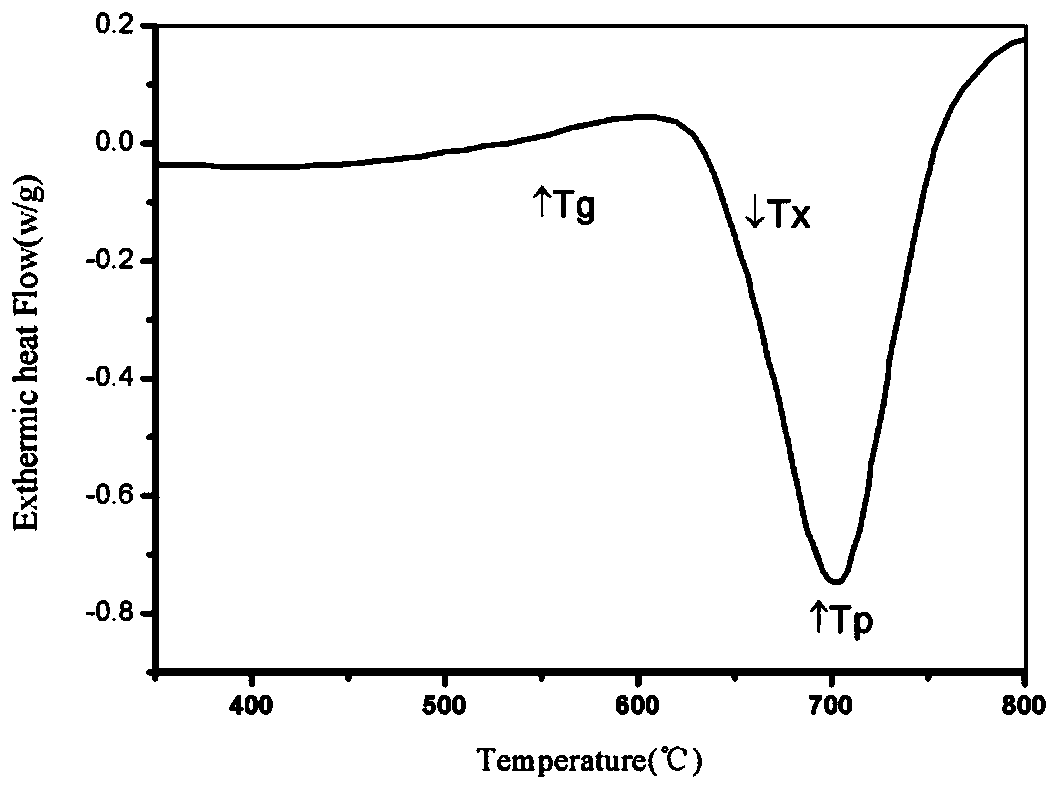

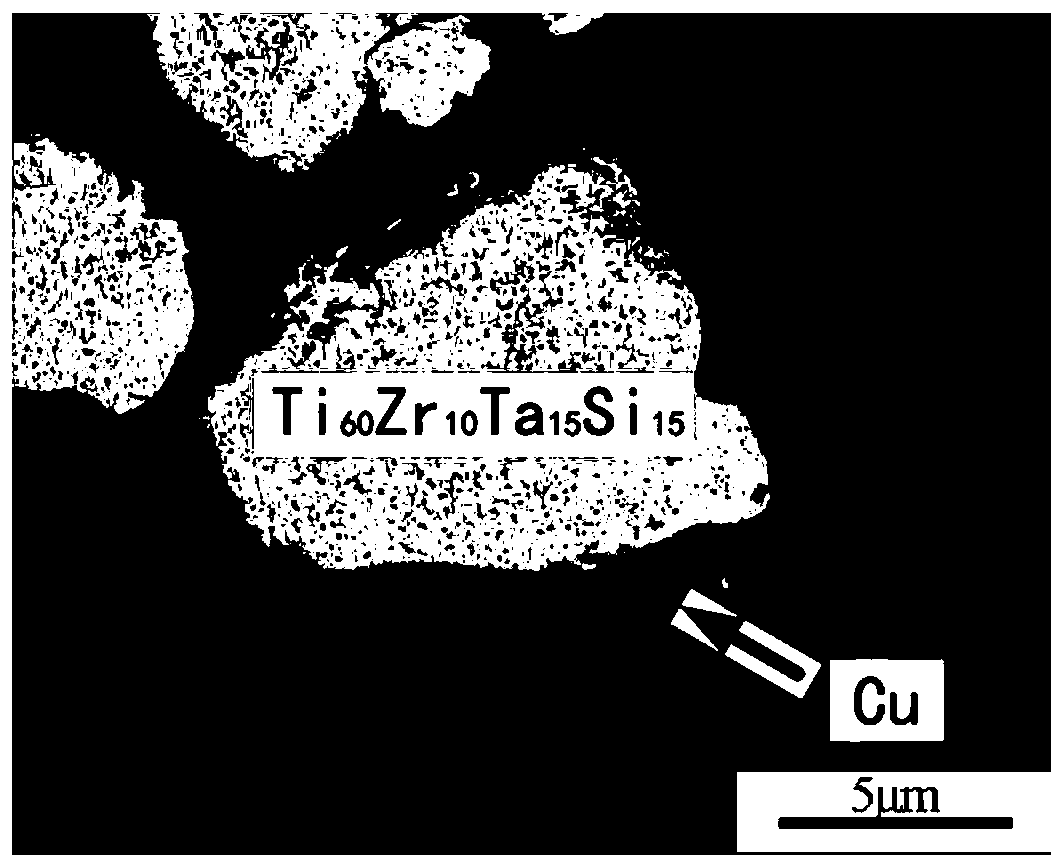

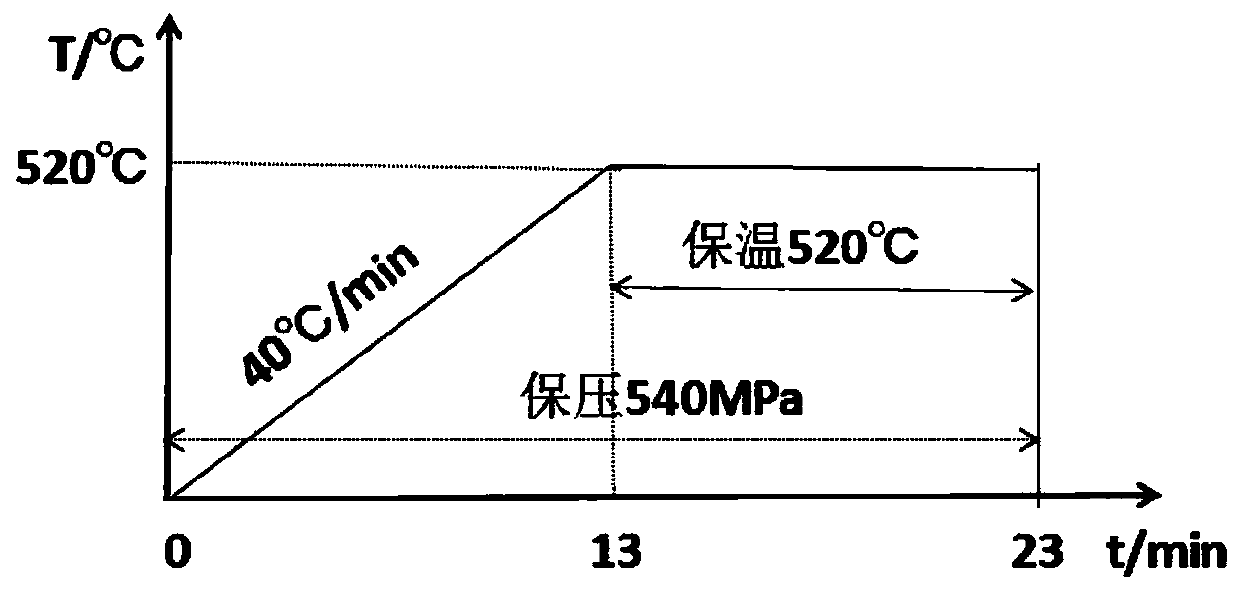

[0045] Please see attached figure 1 As shown, a preparation method of a pure copper toughened biomedical titanium-based amorphous matrix composite material is based on high-purity (99.9999%) powders of Ti, Ta, Si, and Zr that are non-toxic to the human body. Made into Ti by high energy ball milling method 60 Zr 10 Ta 15 Si 15 Nano amorphous spherical powder, comprising the steps of:

[0046] Step 1: Purity of 99.9999% Ti, Ta, Si, Zr respectively according to Ti 60 Zr 10 Ta 15 Si 15 (at.%) Nominal composition, ground into Ti by high-speed ball milling technology 60 Zr 10 -Ta 15 Si 15 Nano-amorphous spherical powder; the grinding balls are prepared according to the mass ratio of the large and small balls as 1:2, the diameters of the large and small balls are 8.731mm and 4.86mm, and the ball-to-material ratio is 20:1. Put it into a 250mL stainle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com