One-component silane-modified polyether sealant with high elasticity and low modulus and preparation method thereof

A technology of silane-modified polyether and low modulus, which is applied in the field of sealant, which can solve the problems of non-paintable limited application range, lack of high elasticity, low modulus, insufficient UV resistance, etc., and achieve excellent tensile strength and fracture Elongation, low production cost, good ductility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

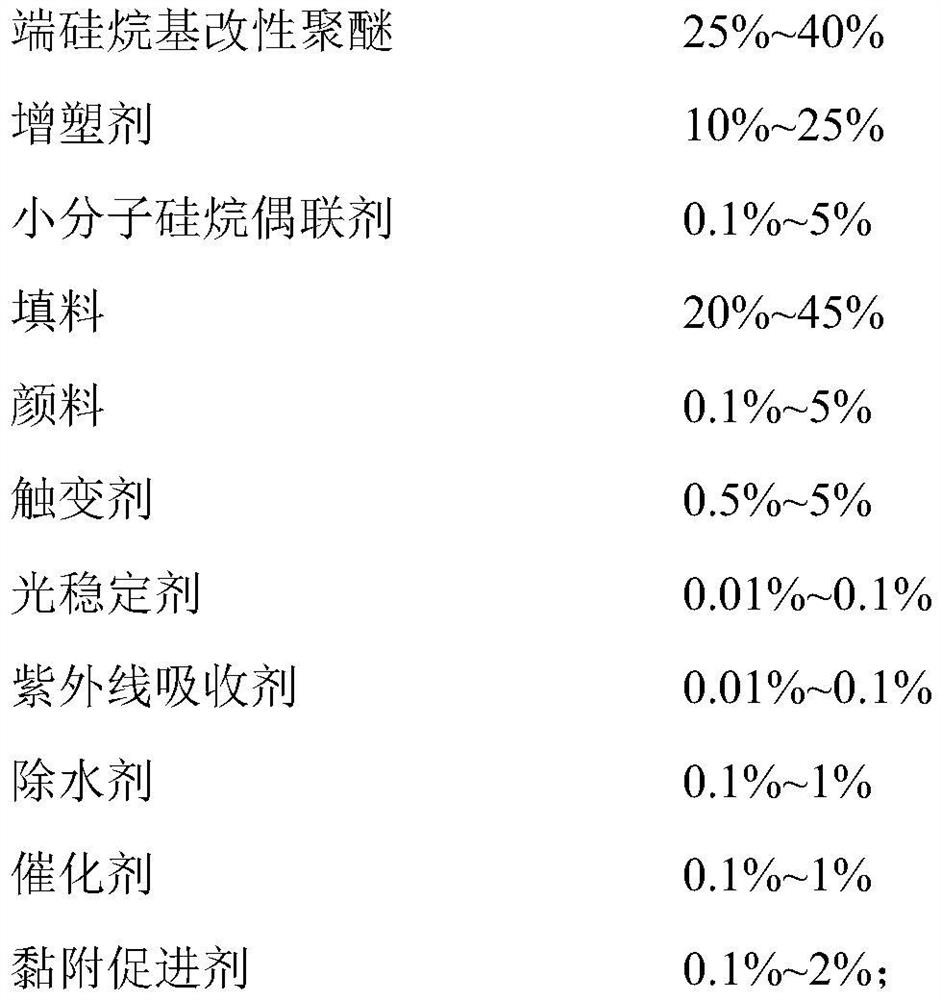

[0041] A high-elasticity and low-modulus one-component silane-modified polyether sealant, made of the following components in parts by weight:

[0042]

[0043] The small-molecule silane coupling agent is a small-molecule compound that contains urethane bonds and is terminated by siloxane at both ends.

[0044] The small-molecule silane coupling agent is obtained by stirring and refluxing at 30°C to 70°C for 60min to 180min at both ends of an aminosilane coupling agent, an isocyanatosilane coupling agent and an organic solvent under the condition of being isolated from air. Blocked silane coupling agent;

[0045]Alternatively, the small molecule silane coupling agent is a two-terminal siloxane obtained by stirring and refluxing at 30°C to 60°C for 30min to 120min under the isolation of air from organic polyamines, isocyanate silane coupling agents and organic solvents. Blocked silane coupling agent;

[0046] Alternatively, the small molecule silane coupling agent is an am...

Embodiment 2

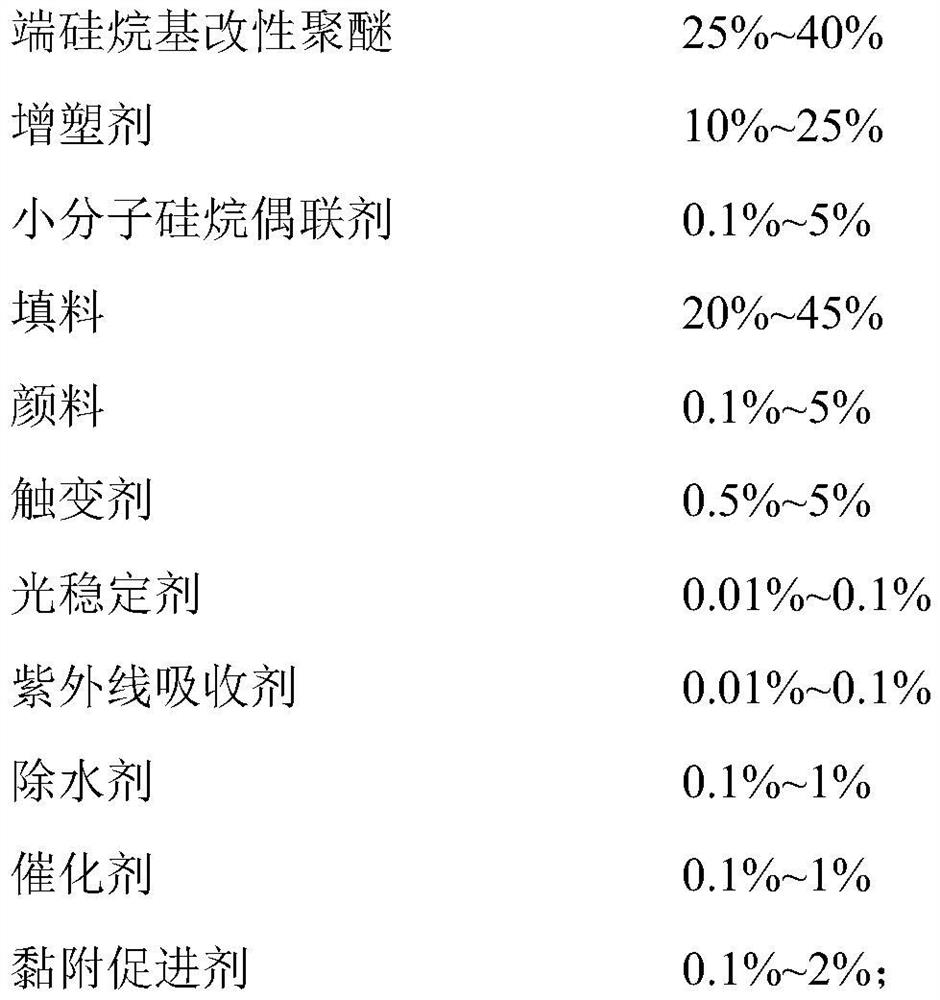

[0074] A high-elasticity and low-modulus one-component silane-modified polyether sealant, made of the following components in parts by weight:

[0075]

[0076] The small molecule silane coupling agent is a small molecule compound that contains urethane bonds and is terminated by siloxane at both ends.

[0077] Wherein, the synthesis of small molecule silane coupling agent: in the 250ml four-neck flask with reflux, stirring and dropping funnel, add the xylene solvent of 150g and the aminosilane coupling agent of adding 11.05g, heat up to 60°C, and then use a constant pressure dropping funnel to drop 10.25g of isocyanate-based silane coupling agent, and continue stirring for 80 minutes to obtain a silane coupling agent with urethane bonds capped at both ends.

[0078] In this embodiment, the aminosilane coupling agent is a silane coupling agent containing a primary amino group, and the silane coupling agent containing a primary amino group is γ-aminopropyltrimethoxysilane. ...

Embodiment 3

[0095] A high-elasticity and low-modulus one-component silane-modified polyether sealant, made of the following components in parts by weight:

[0096]

[0097]

[0098] The small molecule silane coupling agent is a small molecule compound that contains urethane bonds and is terminated by siloxane at both ends.

[0099] Wherein, the synthesis of small molecule silane coupling agent: in the 250ml four-neck flask with reflux, stirring and dropping funnel, add the n-hexane solvent of 150g and the aminosilane coupling agent of adding 11.1g, heat up to 75°C, and then use a constant pressure dropping funnel to drop 12.4 g of isocyanate-based compounds, and continue to stir for 60 minutes to obtain a silane coupling agent with urethane bonds terminated at both ends.

[0100] In this example, the aminosilane coupling agent is a silane coupling agent containing a primary amino group, and the silane coupling agent containing a primary amino group is γ-aminopropylmethyldimethoxysil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com