Guiding mechanism for hardware stamping die

A stamping die and guiding mechanism technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of mold protection, mold damage, inconvenient mold, etc., achieve high practical performance, simple structure, easy to adjust and fix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

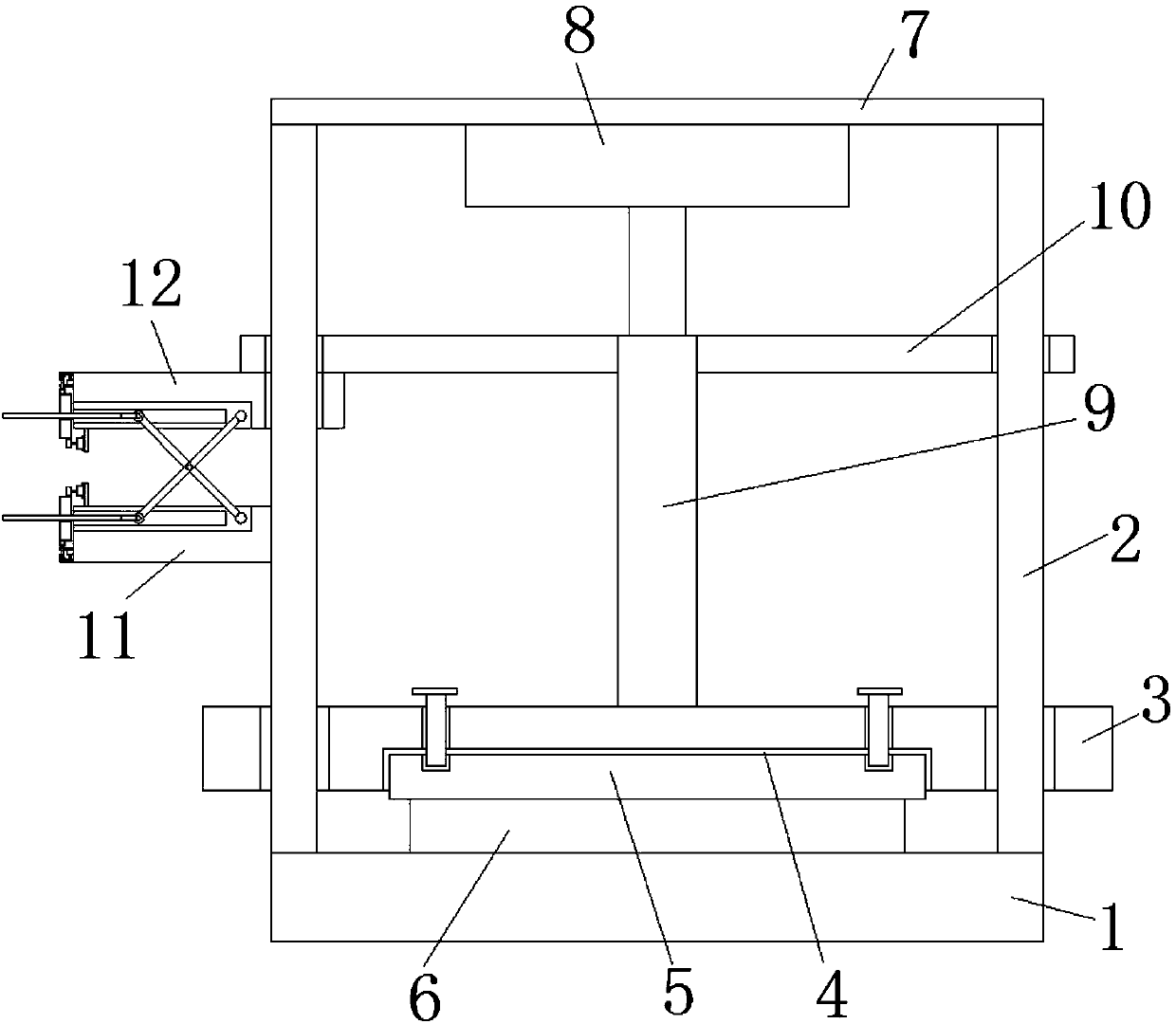

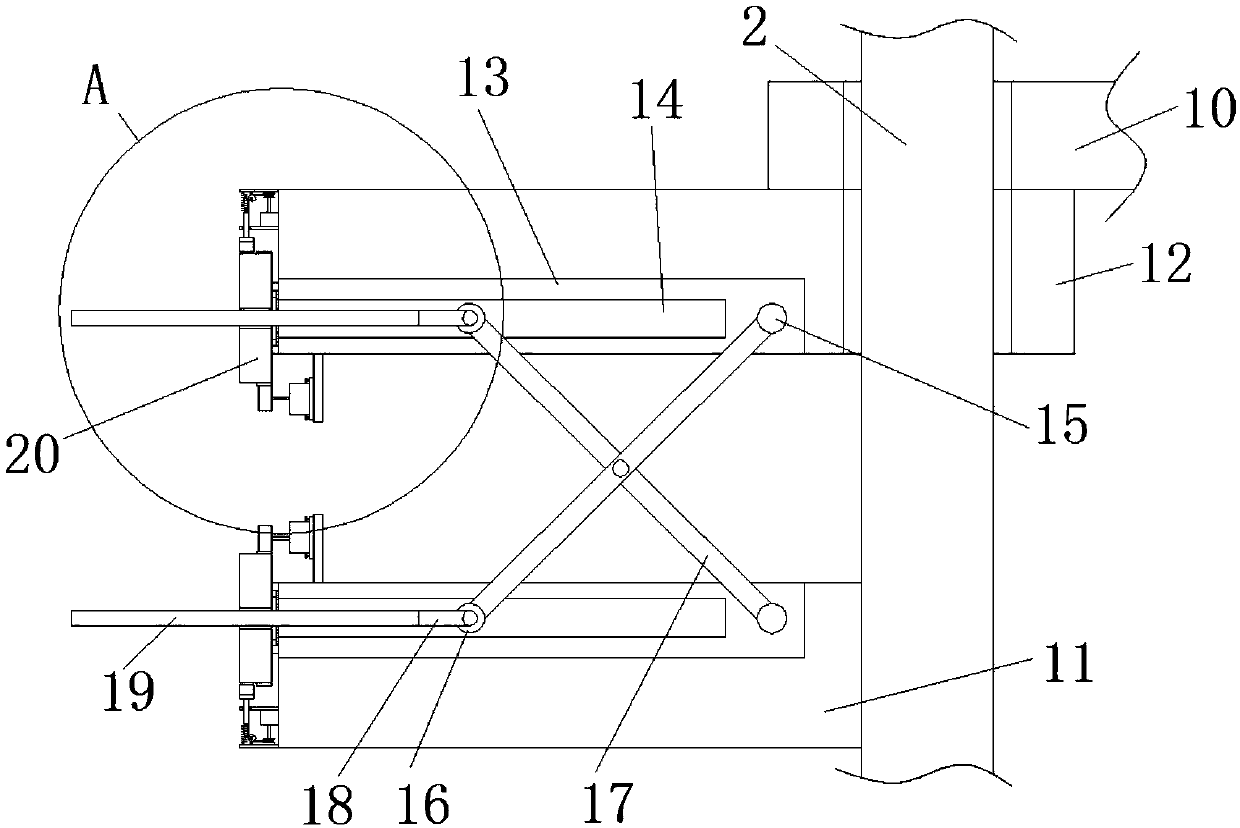

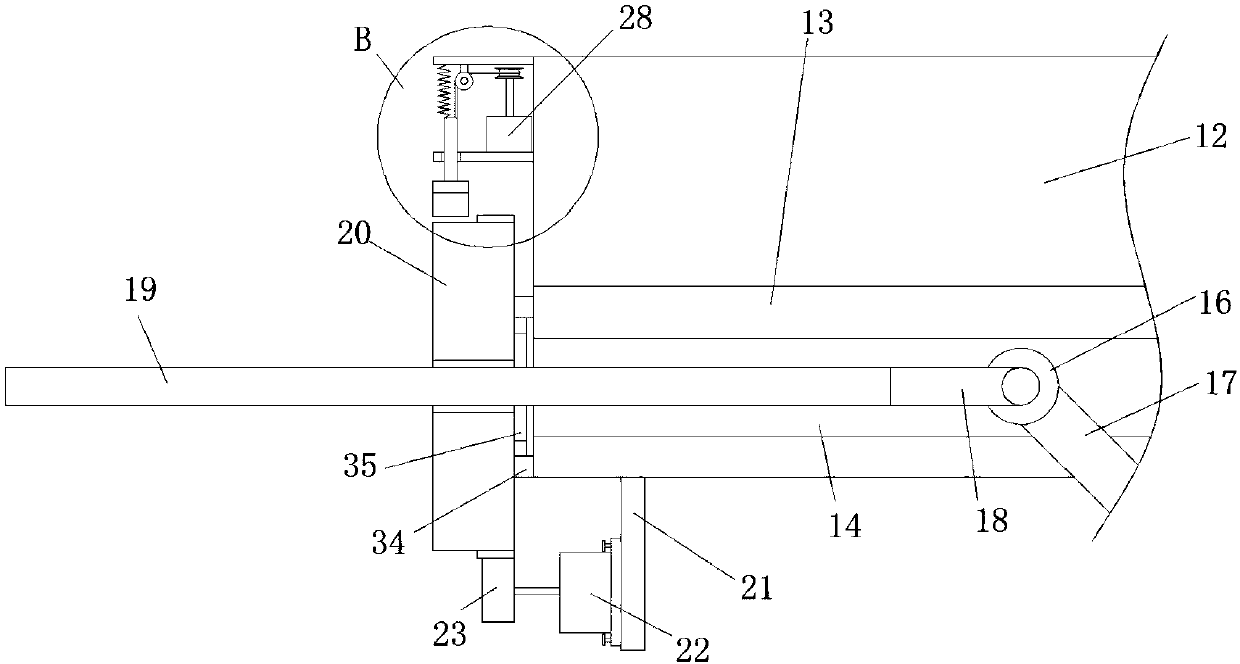

[0022] refer to Figure 1-5In this embodiment, a guide mechanism for a metal stamping die is proposed, including a stamping table 1, a guide column 2 is welded on both sides of the top of the stamping table 1, and the same lifting platform 3 is slidably installed on the two guide columns 2, The bottom of the lifting table 3 is provided with a mounting groove 4, and the internal thread of the mounting groove 4 is installed with a mounting plate 5. The bottom of the mounting plate 5 extends to the bottom of the lifting table 3 and is equipped with a mold body 6. The tops of the two guide columns 2 are welded with the same support plate 7, the bottom of the support plate 7 is fixedly installed with a hydraulic pump 8, the output shaft of the hydraulic pump 8 is welded with a drive rod 9, and the bottom of the drive rod 9 It is welded with the top of the lifting platform 3, and the outer sides of the two guide columns 2 are slidingly installed with limit rods 10, and the sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com