Sand core chilling block combined structure and design method

A combined structure and design method technology, applied in the direction of mold cores, casting molding equipment, metal processing equipment, etc., can solve problems such as difficulty in placing cold iron, and achieve the effects of accurate size, reduced gas generation, and smooth outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for designing a combined structure of a sand core chill, comprising the following steps:

[0036] Step a: manufacture chilled iron 3 according to the casting process plan and casting structure requirements;

[0037] Step b: According to the casting process plan and the casting structure requirements, complete the design drawings of the parent sand core 1 and the combined sand core, the combined sand core includes the chill iron 3 and the sub-sand core 2;

[0038] Step c: manufacturing the parent sand core 1 according to the design drawing of the parent sand core 1;

[0039] Step d: Manufacture the combined sand core according to the design drawing of the combined sand core. When manufacturing the combined sand core, place the cold iron 3 first, and then manufacture the sub-sand core 2;

[0040] Step e: bonding the combined sand core and the parent sand core 1 together with an adhesive.

[0041] Further, step b includes:

[0042] Step...

Embodiment 2

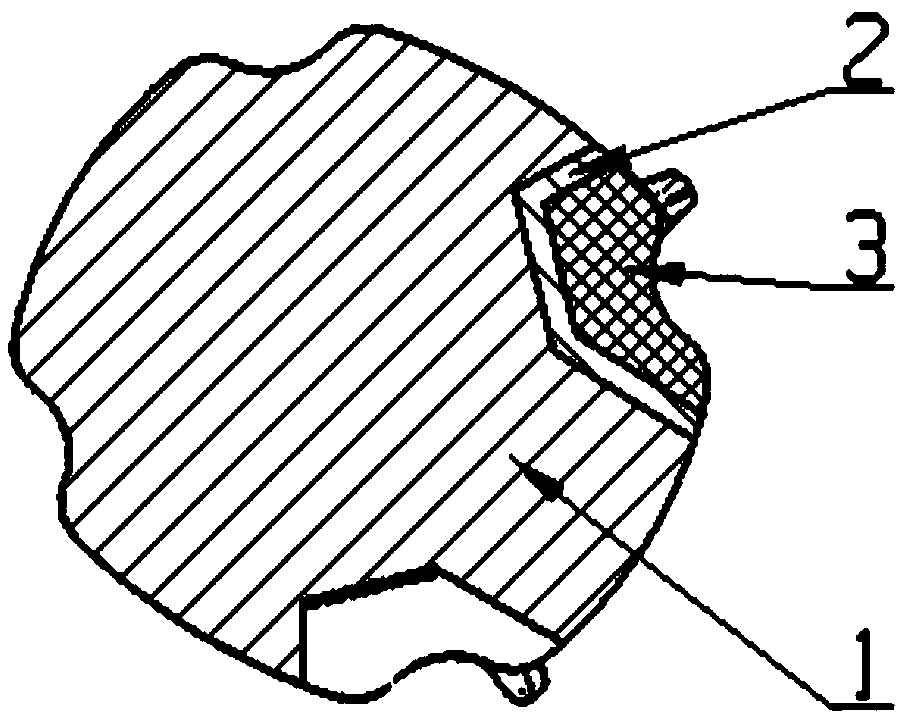

[0067] Such as figure 1 As shown, the present embodiment provides a combined structure of a sand core chill manufactured by the method provided in Embodiment 1, including:

[0068] A parent sand core 1 and a combined sand core; the combined sand core includes a sub-sand core 2 and a cold iron 3; the combined sand core is bonded together with the parent sand core by an adhesive.

[0069] Specifically, both the parent sand core 1 and the sub-sand core 2 are provided with a cavity, the chill iron 3 is located in the cavity of the sub-sand core 2, the sub-sand core 2 is located in the cavity of the parent sand core 1, and the sub-sand core 2 The size of the outer surface matches the size of the inner wall of the mold cavity of the parent sand core 1, and the outer surface of the sub-sand core 2 and the inner wall of the mold cavity of the parent sand core 1 are bonded together by an adhesive.

[0070] The adhesive used in this embodiment is one of cold glue or molding sand adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com