Automatic guitar polishing device

A guitar, automatic technology, used in grinders, belt grinders, grinding/polishing equipment, etc., can solve the problems of poor manual grinding environment, short service life of abrasive belts, difficult installation of abrasive belts, etc. The effect of long service life of abrasive belt and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

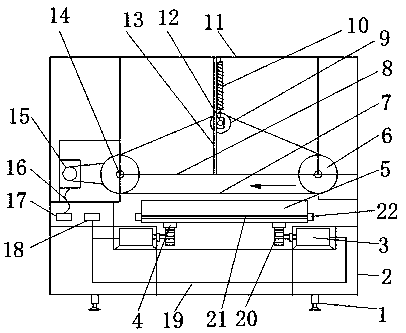

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0014] Example. An automatic guitar polishing device, constituted as figure 1 As shown, a box body 2 is included, the bottom of the lower end of the box body 2 is connected with a support seat 1, a first roller 14 is arranged in the upper end of the box body 2, and a first motor 15 is connected to one side of the first roller 14. The two sides of 14 are connected with horizontal connecting rod 8, and the other end of two horizontal connecting rods 8 is connected with the second roller 6 opposite to the inner side, and the middle position of horizontal connecting rod 8 is connected with vertical sliding rod 13, and the other end of vertical sliding rod 13 The fixed rod 11 is connected, the vertical sliding rod 13 is connected with the slider 12 through the chute, the slider 12 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com