Consumable electrode and its preparation method and application in melting and forming of titanium alloy ingot

A technology of consumable electrodes and alloy ingots, applied in the field of alloy casting, can solve problems such as difficulty in controlling the uniformity of alloy composition, and inability to overcome the problem of element segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

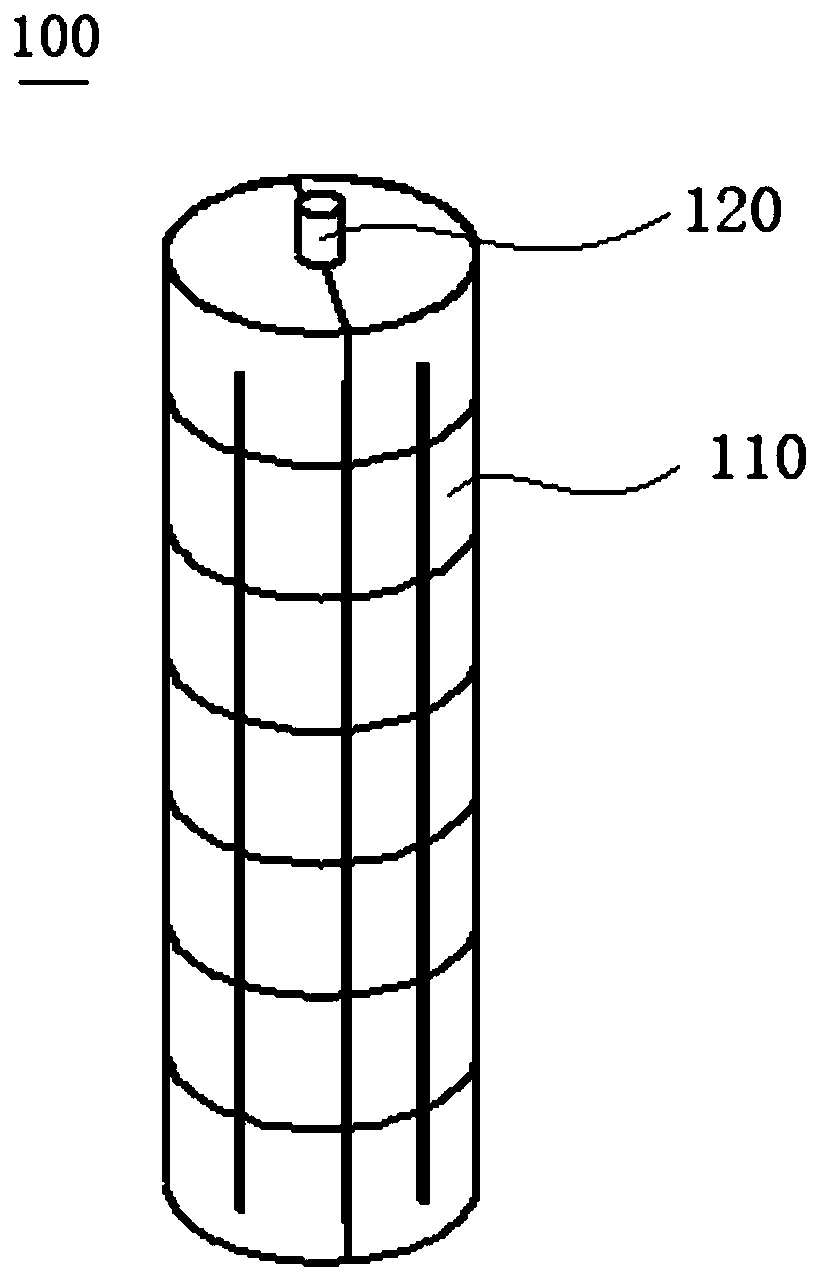

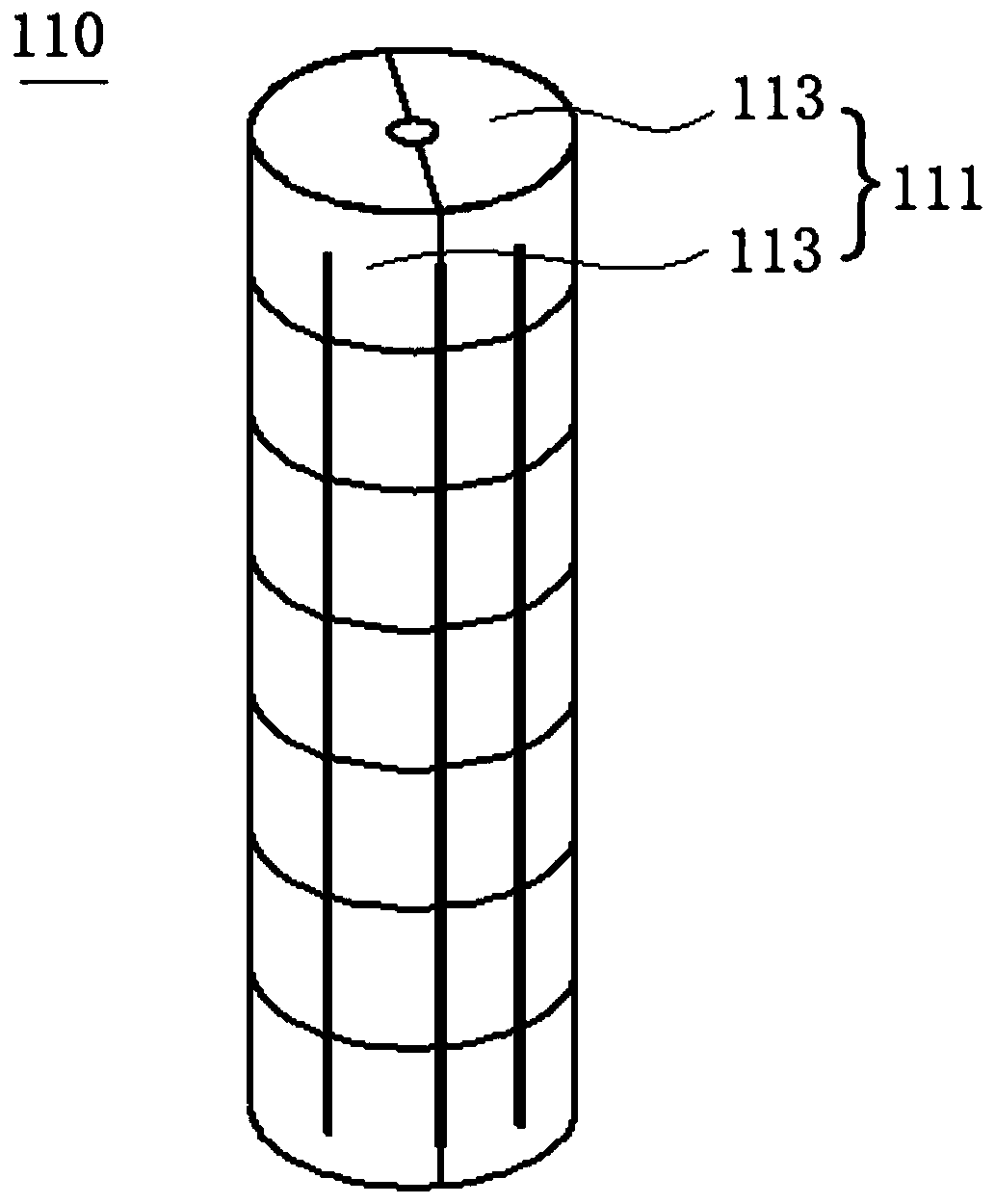

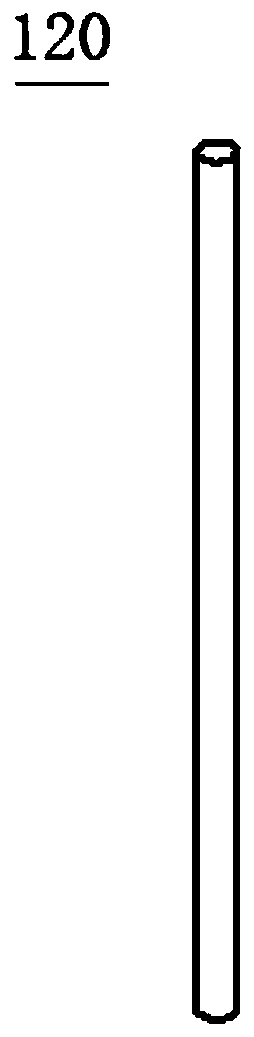

[0047] The method for preparing the above-mentioned consumable electrode according to one embodiment includes the following steps S1-S3.

[0048] Step S1: According to the type and content of each element required by the alloy ingot to be prepared corresponding to the consumable electrode, configure the raw material of the consumable electrode body, and make the raw material of the consumable electrode body into the above-mentioned consumable electrode body .

[0049] It can be understood that the raw materials for configuring the main body of the consumable electrode according to the types and contents of the elements required by the alloy ingot to be prepared corresponding to the consumable electrode can be obtained by conventional methods in the field.

[0050] Further, in step S1, the step of making the raw material of the consumable electrode main body into a consumable electrode main body provided with through holes in the axial direction includes the following steps: ma...

Embodiment 1

[0068] The preparation method of Ti1023 alloy ingot containing positive segregation of Fe element is as follows. The main component of Ti1023 alloy is Ti-10V-2Fe-3Al. Among the main elements, Fe is an element that is prone to positive segregation.

[0069] Preparation of the main body of the consumable electrode: According to the GB3620.1-2007 standard, the addition value of each element of the alloy is set to provide raw materials, wherein the target value of Fe in the ingot is 1.85wt%, and the Fe in the main body of the consumable electrode is 1.88wt%. dispensed. According to the ratio of height to diameter of the ingot and the ratio of the crucible in the melting process, the raw materials are pressed into such figure 2 The semi-circumferential sub-electrode block shown has an outer diameter of Φ340 mm, and the weight of the sub-electrode block is not more than 40 kg. The two sub-electrode blocks are spliced around the central rod along the circumferential direction t...

Embodiment 2

[0077] The preparation method of Ti1023 alloy ingot containing positive segregation of Fe element is as follows. The main component of Ti1023 alloy is Ti-10V-2Fe-3Al. Among the main elements, Fe is an element that is prone to positive segregation.

[0078] Preparation of the main body of the consumable electrode: According to the GB3620.1-2007 standard, the addition value of each element of the alloy is set to provide raw materials, wherein the target value of Fe in the ingot is 1.85wt%, and the Fe in the main body of the consumable electrode is 1.92wt%. dispensed. According to the ratio of height to diameter of the ingot and the ratio of the crucible in the melting process, the raw materials are pressed into such figure 2 The semicircular sub-electrode block shown has an outer diameter of Φ420mm, and the weight of the sub-electrode block is not more than 50 kg. The two sub-electrode blocks are spliced around the central rod along the circumferential direction to form an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com