Solidifying method for bottom pouring type poured steel ingot

A bottom-casting and steel ingot technology is applied in the solidification field of bottom-casting cast steel ingots, which can solve the problems of segregation of large and high-quality steel ingots, easy to cause waste, poor solidification quality, etc., so as to improve production efficiency, improve solidification quality, and solve elements The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

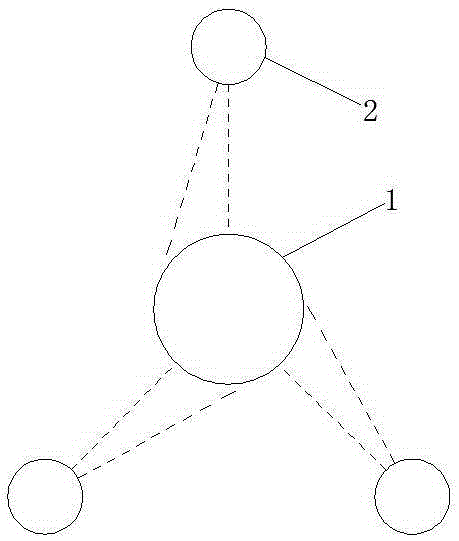

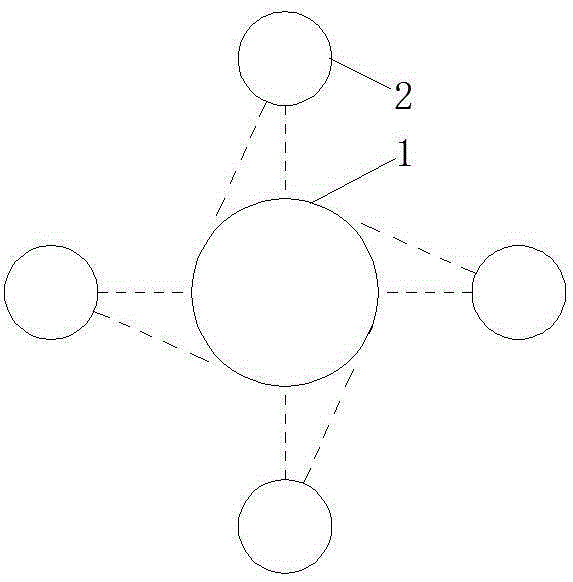

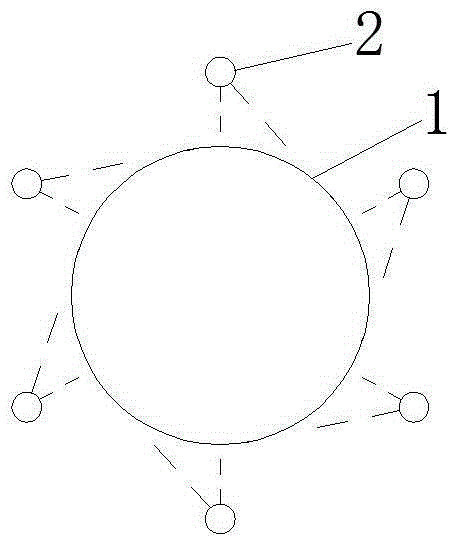

[0049] Cool the Cr5 steel ingot 1 with a diameter of 220cm and take λ as 0.7. After the casting of the steel ingot 1 starts, six fans with a set speed of 3000r / min are used to blow air to the bottom cast steel ingot 1 to accelerate the cooling. 2 The distance from the outer wall of the steel ingot 1 is maintained at 50 cm and is evenly arranged around the steel ingot 1. The ventilator 2 adopts a tangential circular method to blow and cool the steel ingot 1 for 9.4 hours.

[0050] After the ingot 1 is solidified, a low-magnification inspection is carried out, and it is concluded that the product grade of the ingot 1 is 0.5; the flaw detection is carried out on the ingot 1, and the conclusion is qualified.

Embodiment 2

[0052] Air cooling is performed on the Cr5 steel ingot 1 with a diameter of 200cm, and λ is 0.6. After the casting of the steel ingot 1 starts, six fans with a set speed of 3000r / min are used to blow air to the bottom cast steel ingot 1 to accelerate the cooling. 2 Maintain a vertical distance of 70cm from the steel ingot 1 and evenly arrange it around the steel ingot 1. The ventilator 2 adopts a tangential circular method to blow and cool the steel ingot 1 for 9.3h.

[0053] After the ingot 1 is solidified, a low-magnification inspection is carried out, and it is concluded that the product grade of the ingot 1 is 0.5; the flaw detection is carried out on the ingot 1, and the conclusion is qualified.

Embodiment 3

[0055] Air cooling is performed on Cr5 steel ingot 1 with a diameter of 180cm, and λ is 0.5. After the casting of steel ingot 1 starts, six fans with a set speed of 3000r / min are used to blow air to the bottom casting steel ingot 1 to accelerate cooling. 2 Maintain a vertical distance of 90cm from the steel ingot 1 and evenly arrange it around the steel ingot 1. The ventilator 2 adopts a tangential circular method to blow and cool the steel ingot 1 for 8 hours.

[0056] After the ingot 1 is solidified, a low-magnification inspection is carried out, and it is concluded that the product grade of the ingot 1 is 0.5; the flaw detection is carried out on the ingot 1, and the conclusion is qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com