Connecting bridge member of concrete external wall

A technology for concrete, exterior walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

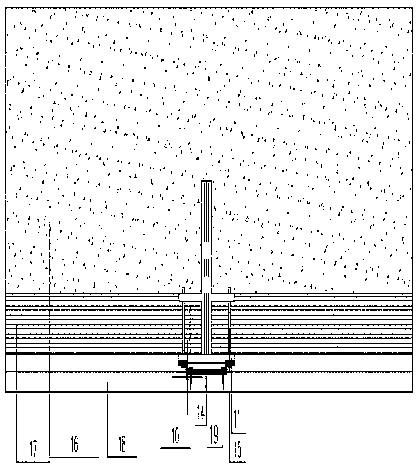

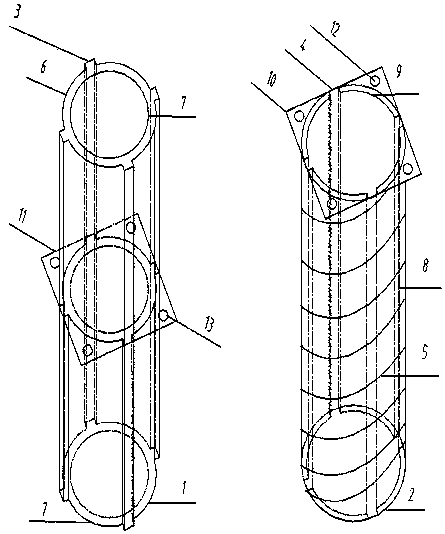

[0031] Such as Figure 1-2 As shown, a connecting bridge for concrete exterior walls, including an embedded hollow pipe (1), an outer hollow pipe (2), an outer convex tooth (3), an inner concave notch (4), a thread (5), an inner Outer wall of embedded hollow pipe fittings (6), inner wall of embedded hollow pipe fittings (7), outer wall of outer jacket hollow pipe fittings (8), inner wall of outer jacket hollow pipe fittings (9), connecting plate of outer jacket hollow pipe fittings (10), connecting plate of embedded hollow pipe fittings (11 ), reserved holes for the fasteners of the connecting plate of the outer hollow pipe fittings (12), reserved holes for the fasteners of the connecting plate of the embedded hollow pipe fittings (13), a few-shaped light keel (14), fasteners (15), concrete Structural walls (16), exterior wall insulation boards (17), exterior wall decorative panels (18) and light keel anchors (19); the connecting bridges of concrete exterior walls are divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com