A device and method for tensile testing of brittle tendons

A technology of tensile test and reinforcement, applied in the direction of measuring device, applying stable tension/pressure to test material strength, analyzing material, etc., can solve problems such as cross-section damage, achieve simple device, save test cost, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A device for tensile testing of brittle tendons, comprising a casing 1, a binding nut 2, a ball-and-socket nut 3, and a ball-end tie rod 4.

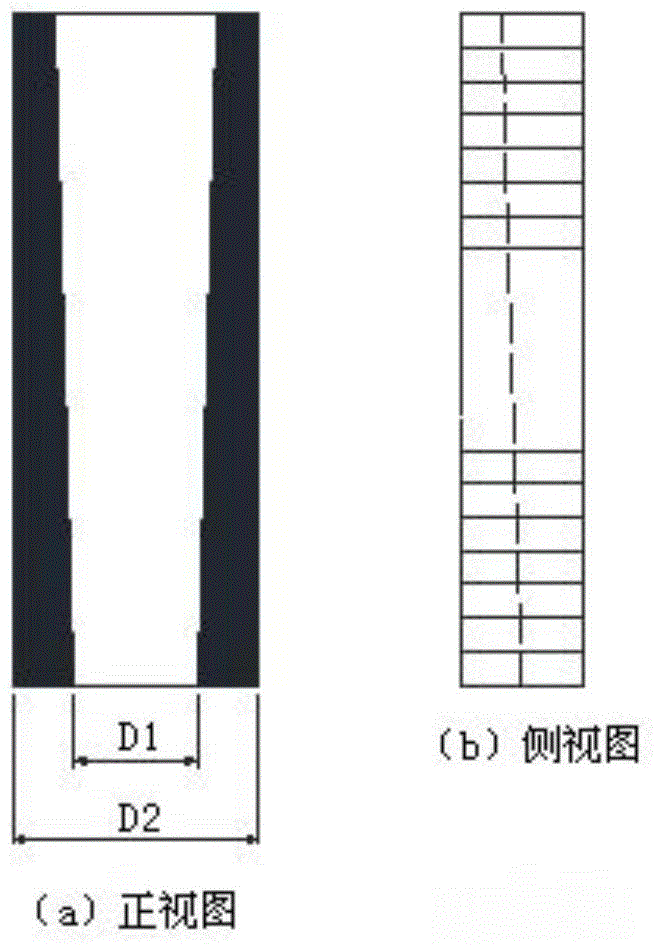

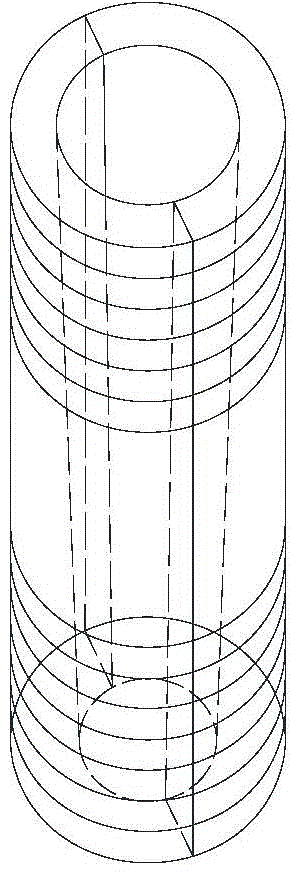

[0032] Such as figure 1 and figure 2 As shown, the casing 1 is assembled from two half-pipes, and a frustum-shaped cavity is formed inside after the assembly. The outside of the casing 1 is in the shape of a cylinder, and the surface of the cylinder is provided with external threads.

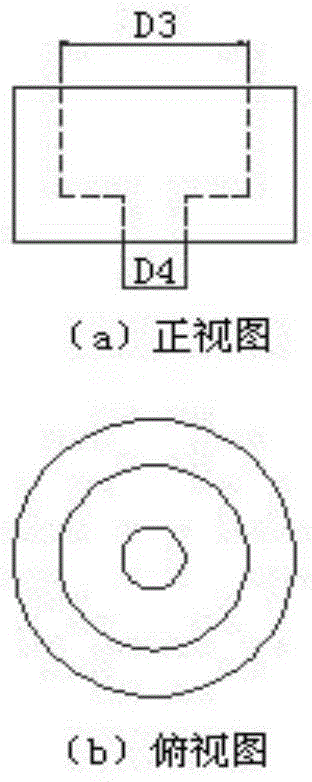

[0033] Such as image 3 and Figure 4 As shown, the binding nut 2 is screwed on the end of the sleeve 1 with a smaller inner diameter.

[0034] Such as Figure 5-7 As shown, there is a hemispherical cavity inside the ball-and-socket nut 3, one end of the ball-joint tie rod 4 is spherical, the ball-joint tie rod 4 can pass through the ball-and-socket nut 3, and the ball head at the end of the ball-joint tie rod 4 is placed in a hemispherical shape. In the cavity, it can rotate flexibly.

[0035] Such as Figure 8 As shown, after the ball joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com