3D printing concrete constructional column bottom vertical steel bar anchoring component and construction method

A technology of 3D printing and vertical reinforcement, which is applied in the direction of building components, building structures, columns, etc., can solve the problems of difficult connection between layers of vertical reinforcement, poor quality of joints, and difficult construction, etc., to achieve the reduction of interlayer The effect of linking construction difficulty, fast construction speed and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

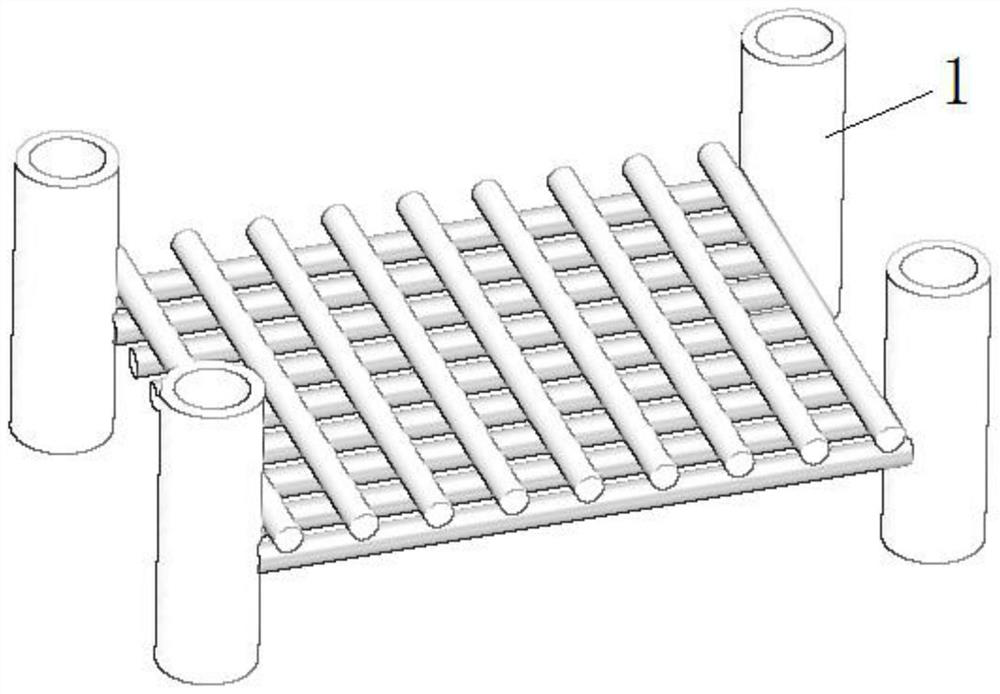

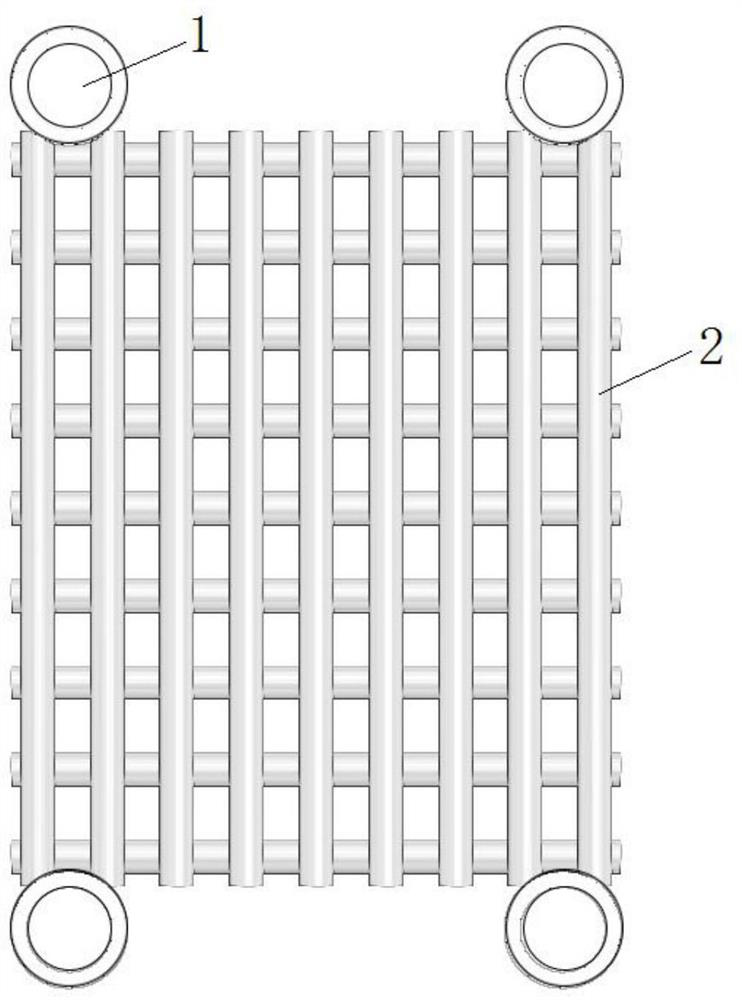

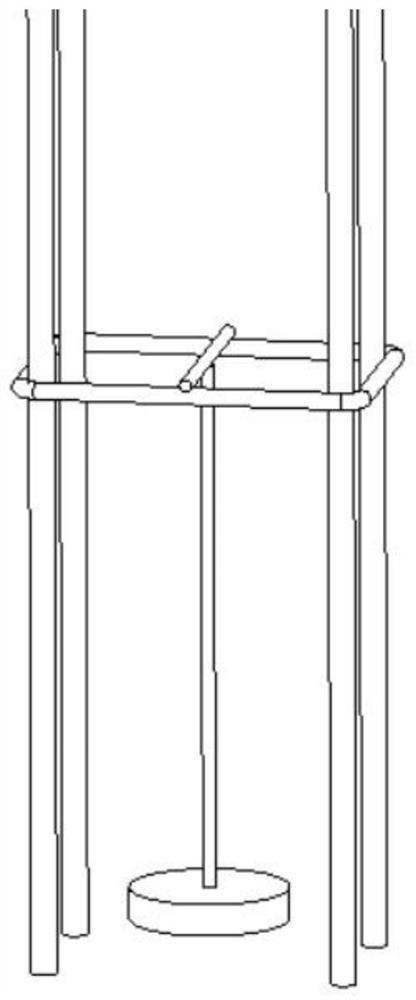

[0044] Specific implementation mode one: see Figure 1-12 This embodiment will be described. The 3D printed concrete structural column bottom vertical reinforcement anchorage component described in this embodiment includes a combined steel sleeve prefabricated component 5, a number of overlapping steel bars 9, a number of fixed bolt prefabricated components, a lapped end plate prefabricated component and a reinforcement cage 12, The combined steel sleeve prefabricated component 5 is pre-embedded on the concrete beam or slab 3, and a number of overlapping steel bars 9 are longitudinally placed inside the combined steel sleeve prefabricated component 5, and each fixed bolt prefabricated component is installed on one overlapping steel bar 9 , a prefabricated reinforcement cage 12 is installed on the overlapping reinforcement 9, and a prefabricated member of an overlapping end plate is installed on the lower part of the reinforcement cage 12, and the vertical overlapping reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com