Prefabricated building and component anchoring method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

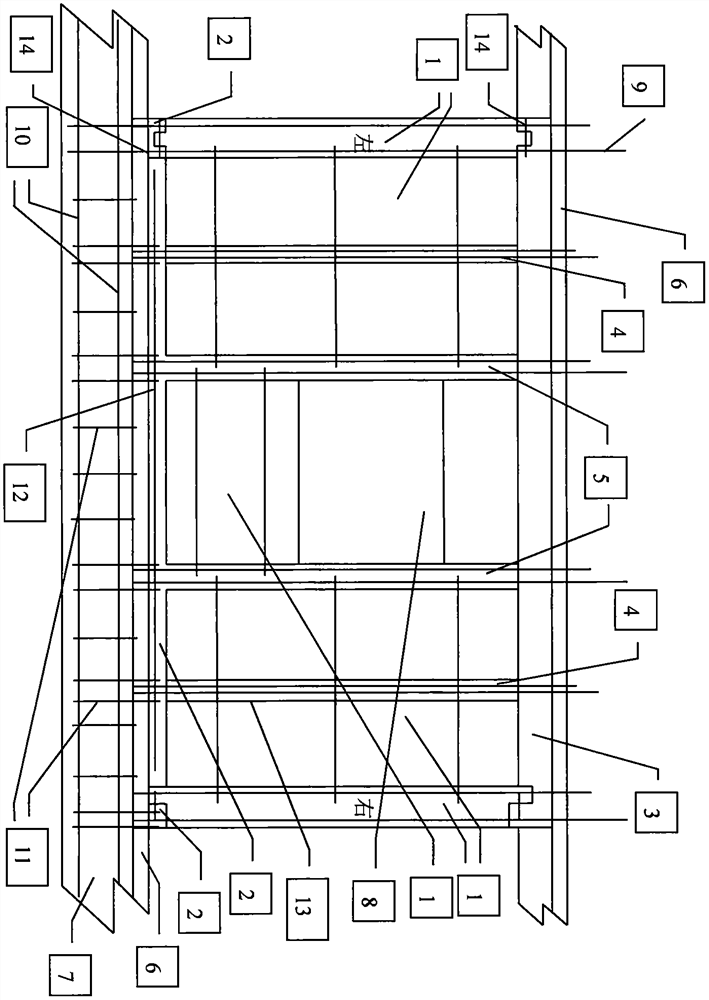

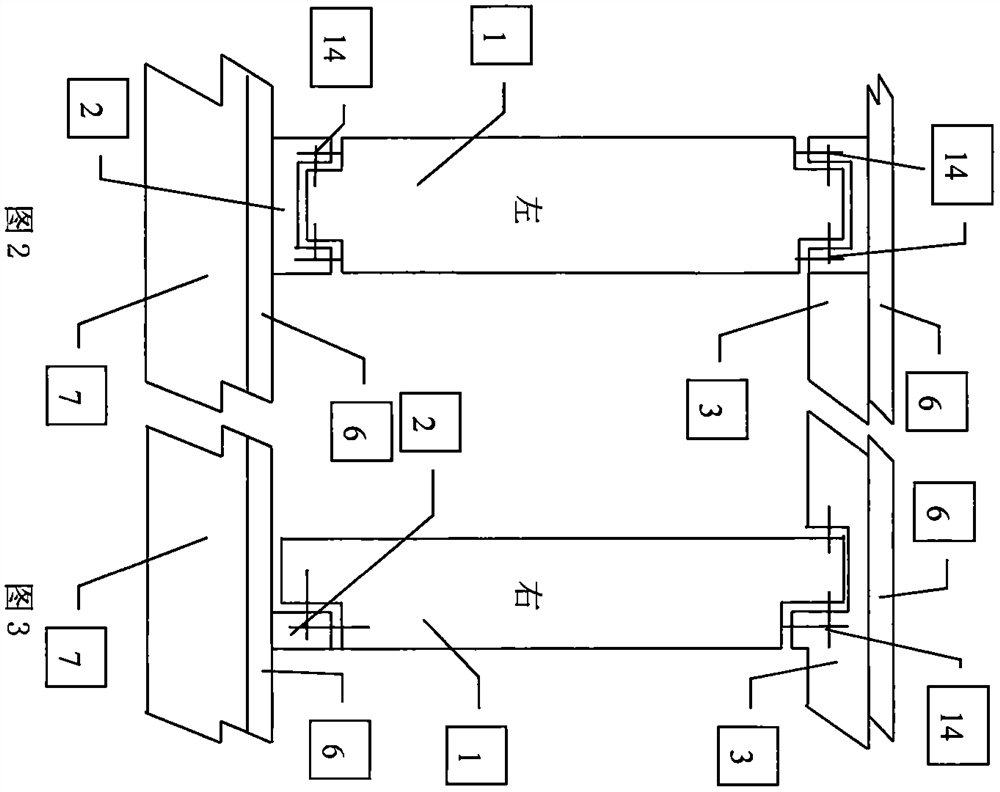

[0022] In order to make the technical means realized by the present invention, creation feature, reach purpose and effect easy to understand, the building of a full shear wall raft (strip) foundation without basement is further set forth the present invention below as an embodiment, for It is convenient to understand the anchoring methods of 2 kinds of prefabricated wall panels in the application of the present invention, figure 1 The two kinds of anchoring methods of prefabricated wall panels are illustrated by means of cross-sectional diagrams, without specific dimensioning, figure 1 The anchoring method of the prefabricated wall panel on the left adopts the anchoring method that the prefabricated wall panels with "convex" shape at both ends are respectively anchored into the inverted "concave" shaped cast-in-place concrete beam and the "concave" shaped cast-in-situ anchor beam; figure 1 The anchoring method of the prefabricated wall panel on the right adopts the method of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com