Shape memory alloy strain sensor strain value detection method

A technology of strain sensor and memory alloy, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring device, etc., can solve the problems of inaccurate and lack of strain value measurement of shape memory alloy strain sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

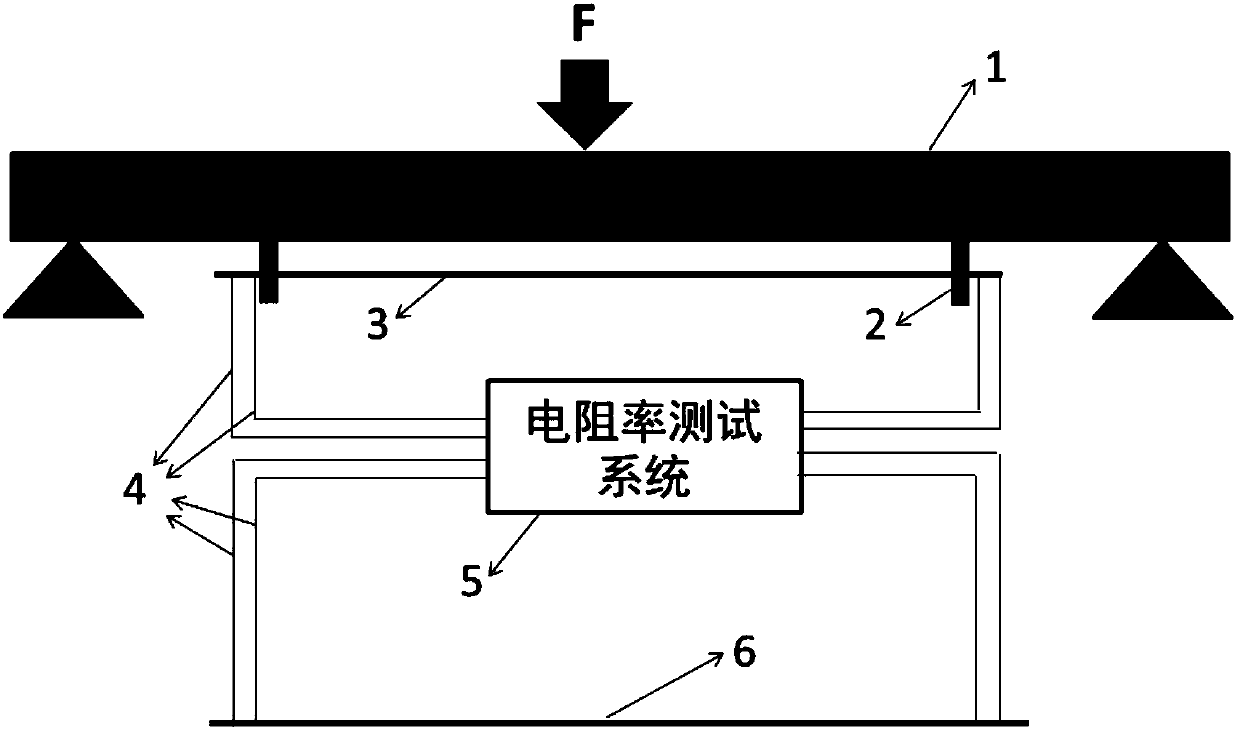

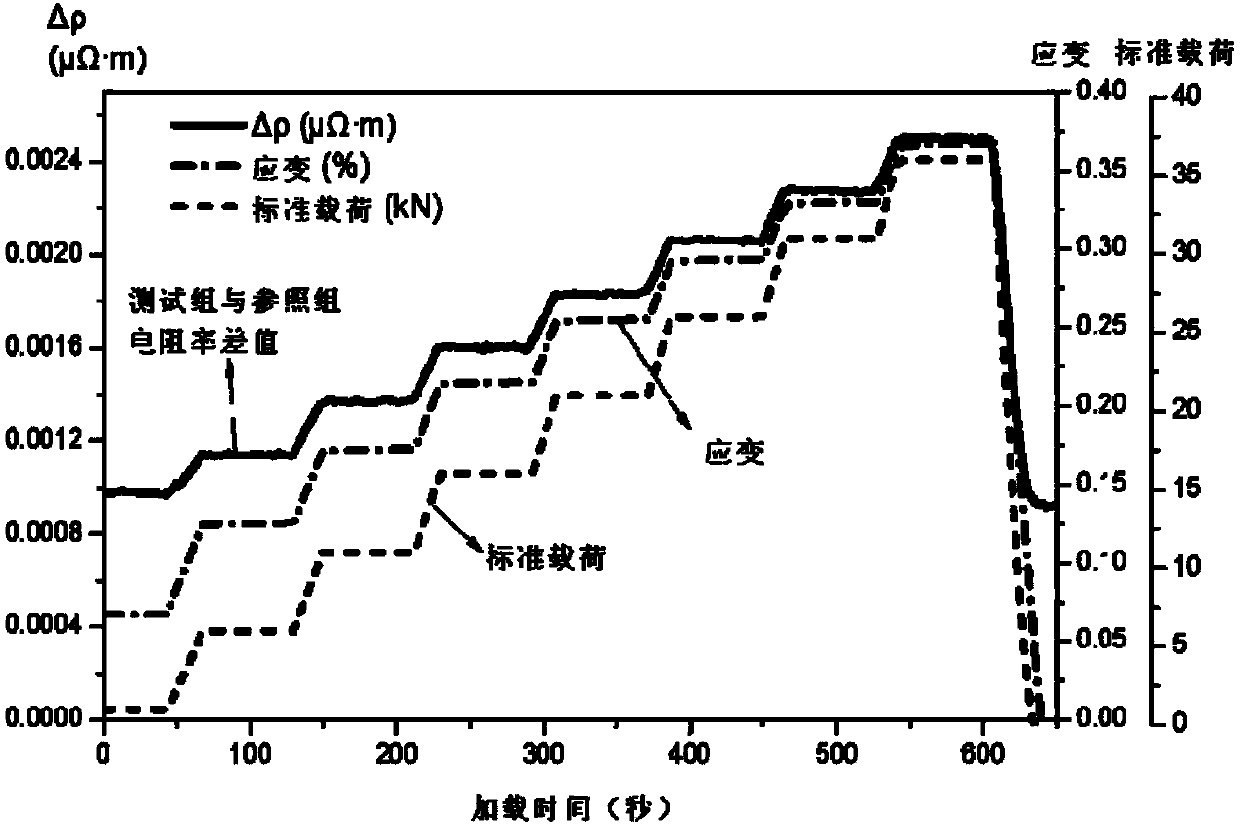

[0065] A method for measuring the strain value of a shape memory alloy strain sensor, using nickel-titanium shape memory alloy wire as a test sensor and a reference sensor respectively, the diameter of the wire is 0.15mm, and the alloy composition is calculated by mass percentage: nickel: 56%; Titanium 44%. Its martensitic transformation initiation temperature M s =-10°C, it is a superelastic alloy wire at room temperature. Such as figure 1 As shown, the length of the component to be tested is 120cm, the width and height are both 15cm, and the two ends of the component are supported by two fulcrums. Hold, and apply a certain prestress to make the test sensor taut, and then solder the 4 wires (two current input lines, two voltage signal output lines) of the resistivity test system to the test sensor. At the same time, connect the four leads of the other test channel to another unstressed reference sensor of the same material.

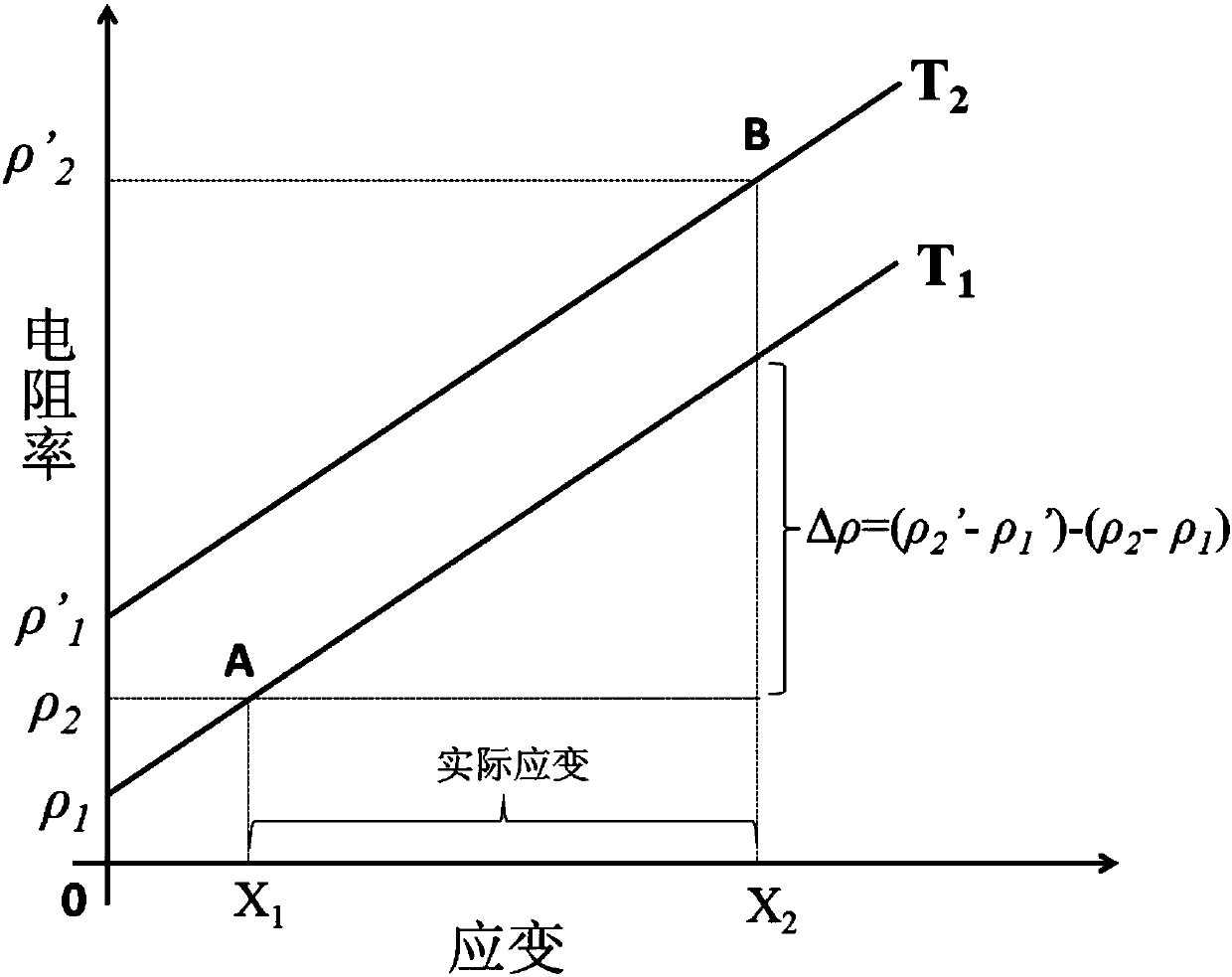

[0066] Such as figure 2 As shown, at the ini...

Embodiment 2

[0068] A method for measuring the strain value of a shape-memory alloy strain sensor. A nickel-titanium shape-memory alloy film is fixed on an adhesive-backed plastic film with a thickness of 10 microns, a width of 3 mm, and a length of 30 mm by adhesive tape to make a basic Shape memory alloy sensor. The thickness of the film is 10 microns. The film is aged and annealed at 400°C for 3 hours, and the martensite transformation end temperature of the film is -40°C. The composition of the film is calculated by mass percentage: nickel: 56%; titanium 44%. During the test, take two pieces of nickel-titanium shape memory alloy films with the same specifications, one is pasted on the object to be tested as a test sensor; the other is in a free state as a reference sensor. Weld the 4 wires (two current input wires, two voltage signal output wires) of the resistivity testing system to the test sensor with soldering. At the same time, connect the four leads of the other test channel to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com