Novel formation slot device and realization method thereof

A realization method and a technology of forming a tank, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of affecting heating efficiency, easy scaling on the surface, small contact area, etc., so that it is not easy to pollute and the cost is cheap , the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

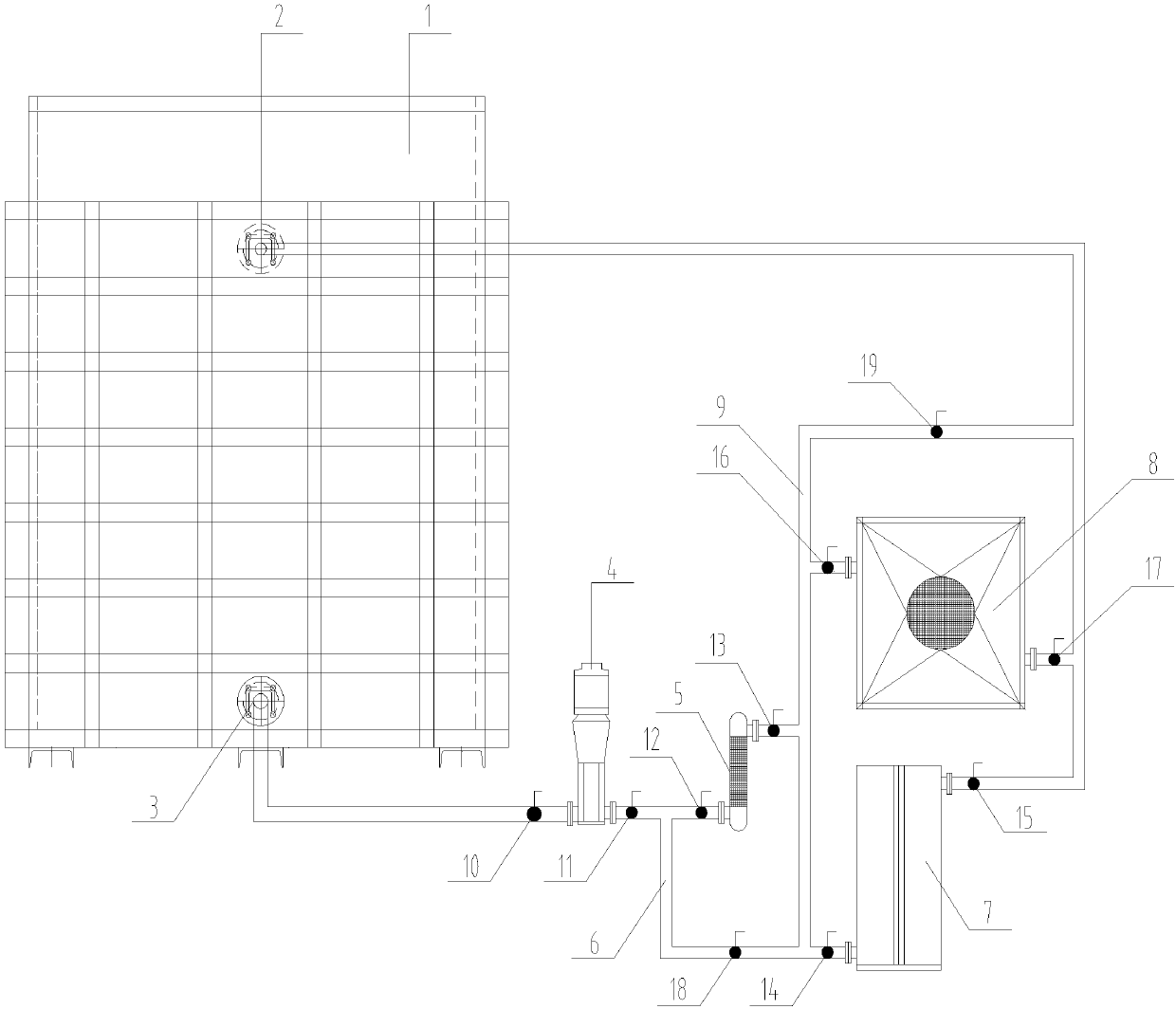

[0027] Such as figure 1 As shown, a new type of formation tank device includes a formation tank, a circulation inlet is provided at the upper end of the formation tank, and a circulation outlet is provided at the lower end of the formation tank. The circulation outlet is connected to a circulation pump through a pipeline, and the circulation pump is connected to a filter. There is a spare pipe between the filters, the spare pipe is connected to the inlet of the heater, the outlet of the filter is respectively connected to the spare pipe and the inlet of the heat exchanger, the inlet of the heat exchanger is also connected to a flow control pipe, and the heater’s The outlet port, the outlet port of the control pipe and the outlet port of the heat exchanger are directly at the circulation inlet.

[0028] In this embodiment, the pipelines on both sides of the circulating pump are provided with a first valve and a second valve; both sides of the filter are provided with a third va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com