Switch cabinet convenient for installing long bus

A switchgear and bus bar technology, applied in the field of switchgear, can solve the problems of troublesome expansion or maintenance, time-consuming and labor-intensive maintenance work, high assembly process requirements, etc., and achieve the effect of convenient and fast installation, smooth installation, convenient expansion and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

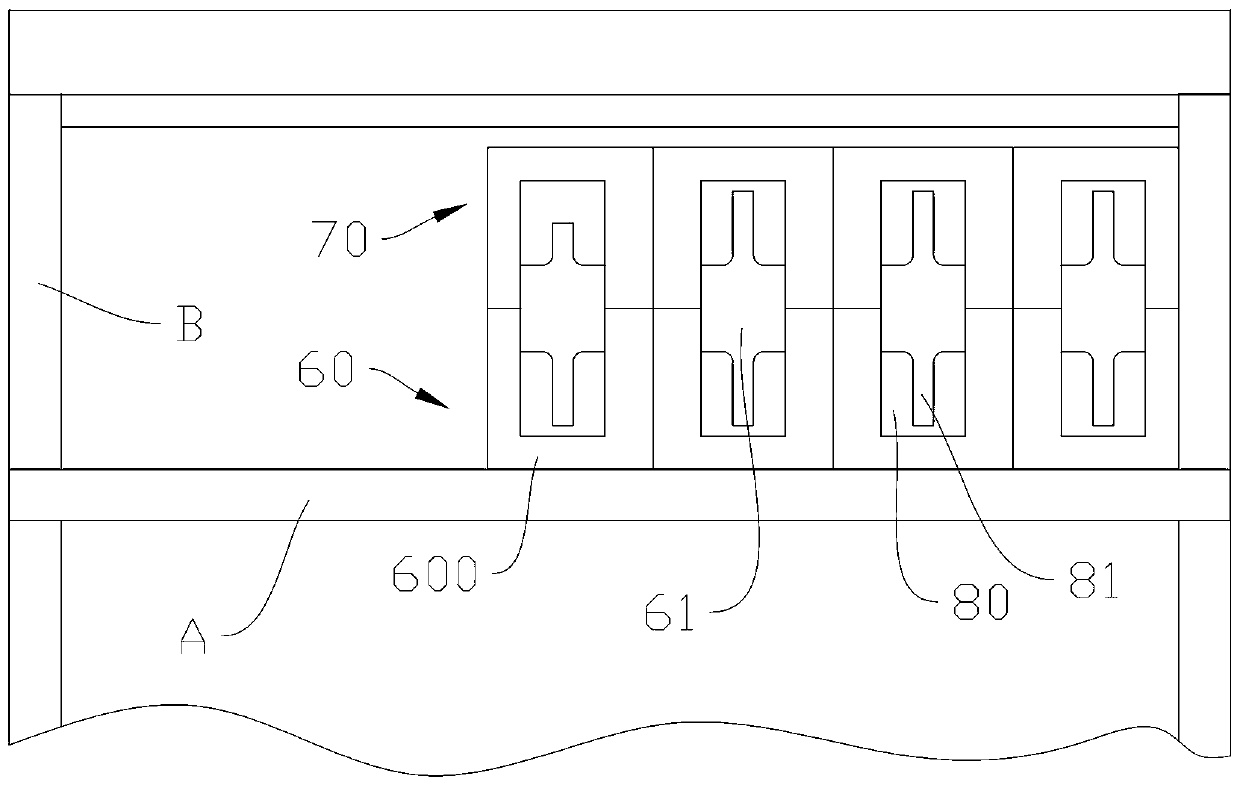

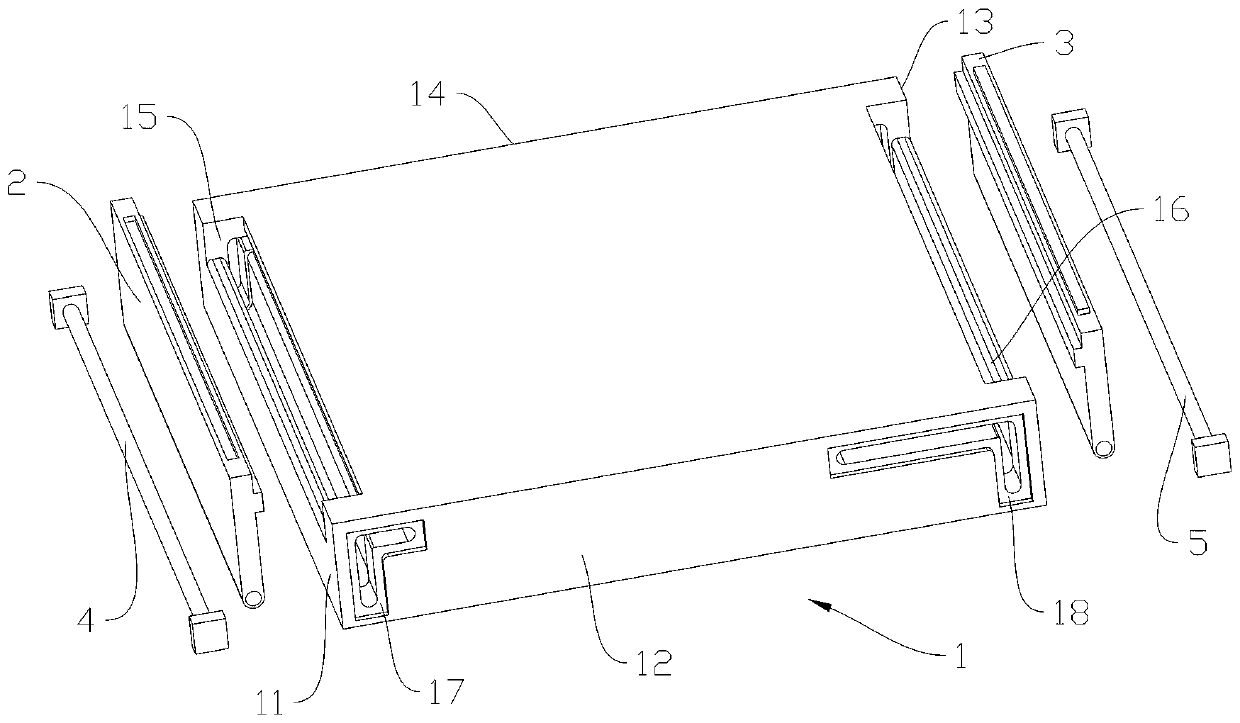

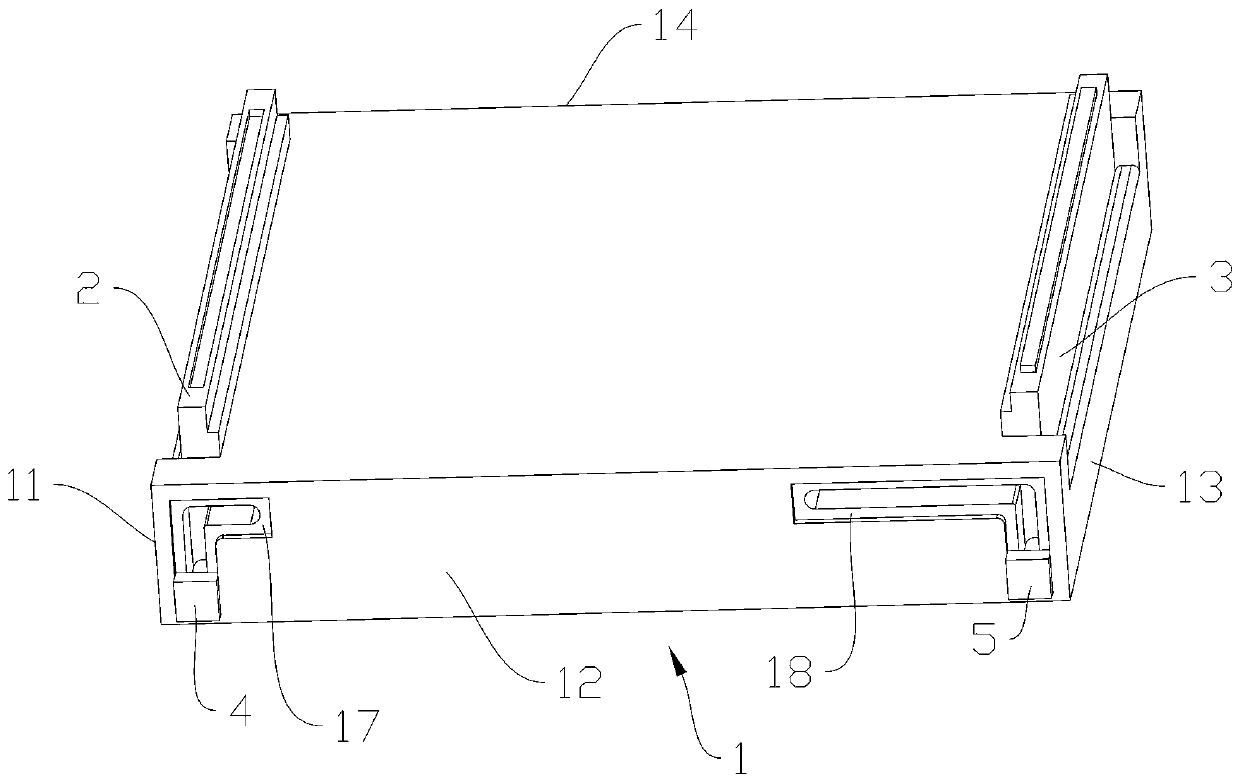

[0038] Example: such as Figure 1-8 As shown, a switchgear for easy installation of long busbars includes a switchgear body B, a detachable cabinet top on the switchgear body B, a busbar bridge A on the lower end of the cabinettop, and a busbar bridge A on the busbar The busbar frame; the cabinet top includes a plurality of cabinet top modules 100 that are slid into each other, and the cabinet top module 100 includes a cabinet top module body 1, and the cabinet top module body 1 has a first end 11, a second end 12, and a second end that are sequentially adjacent to each other. The three ends 13 and the fourth end 14 are characterized in that: the cabinet top module also includes a first slide insert 2 which can move in multiple directions at the first end 11 and a multi-directional movement at the third end 13. The moving second sliding insert 3 , the first control member 4 passing through between the second end 12 and the fourth end 14 and rotatably connected with the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com