Seal ring on cover plate component, cover plate component, upper cover component and electric appliance

A sealing ring and cover assembly technology, which is applied to engine sealing, engine components, cooking utensil lids, etc., can solve problems affecting customer experience, condensed water condensation, etc., and achieve good customer experience, good sealing effect, and enhanced rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

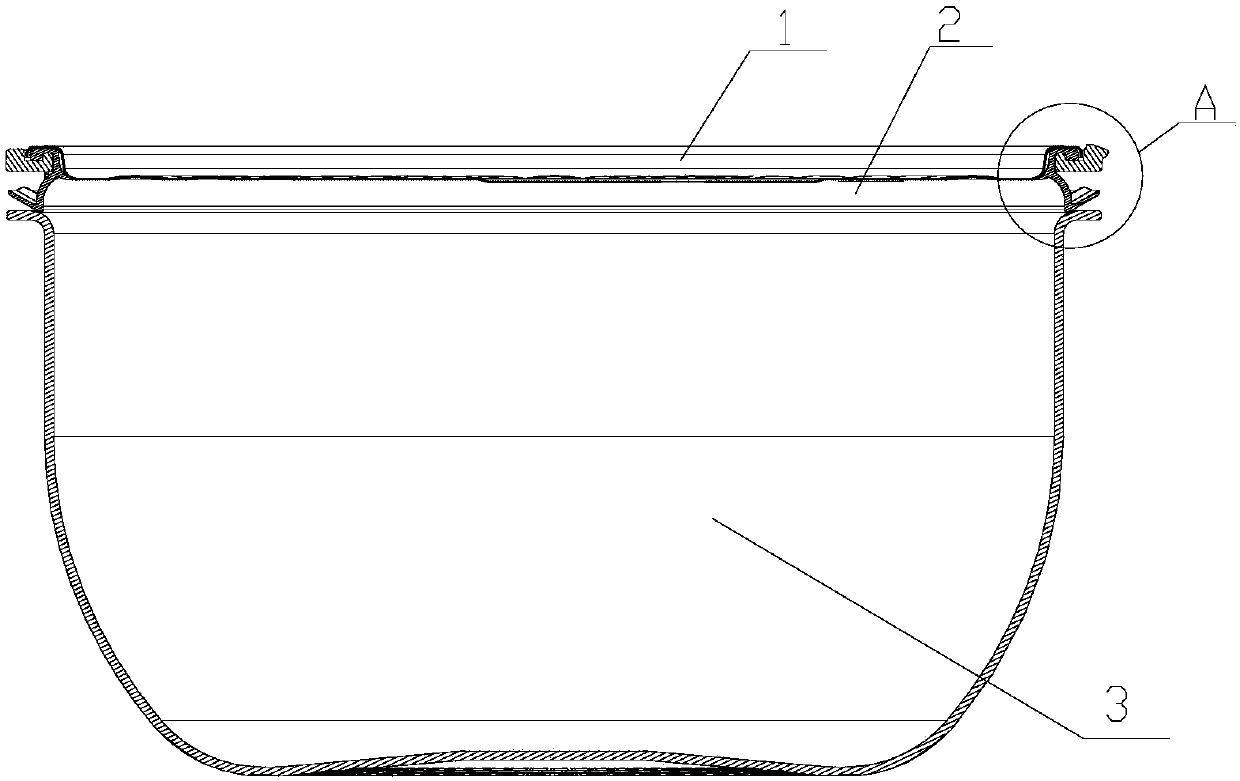

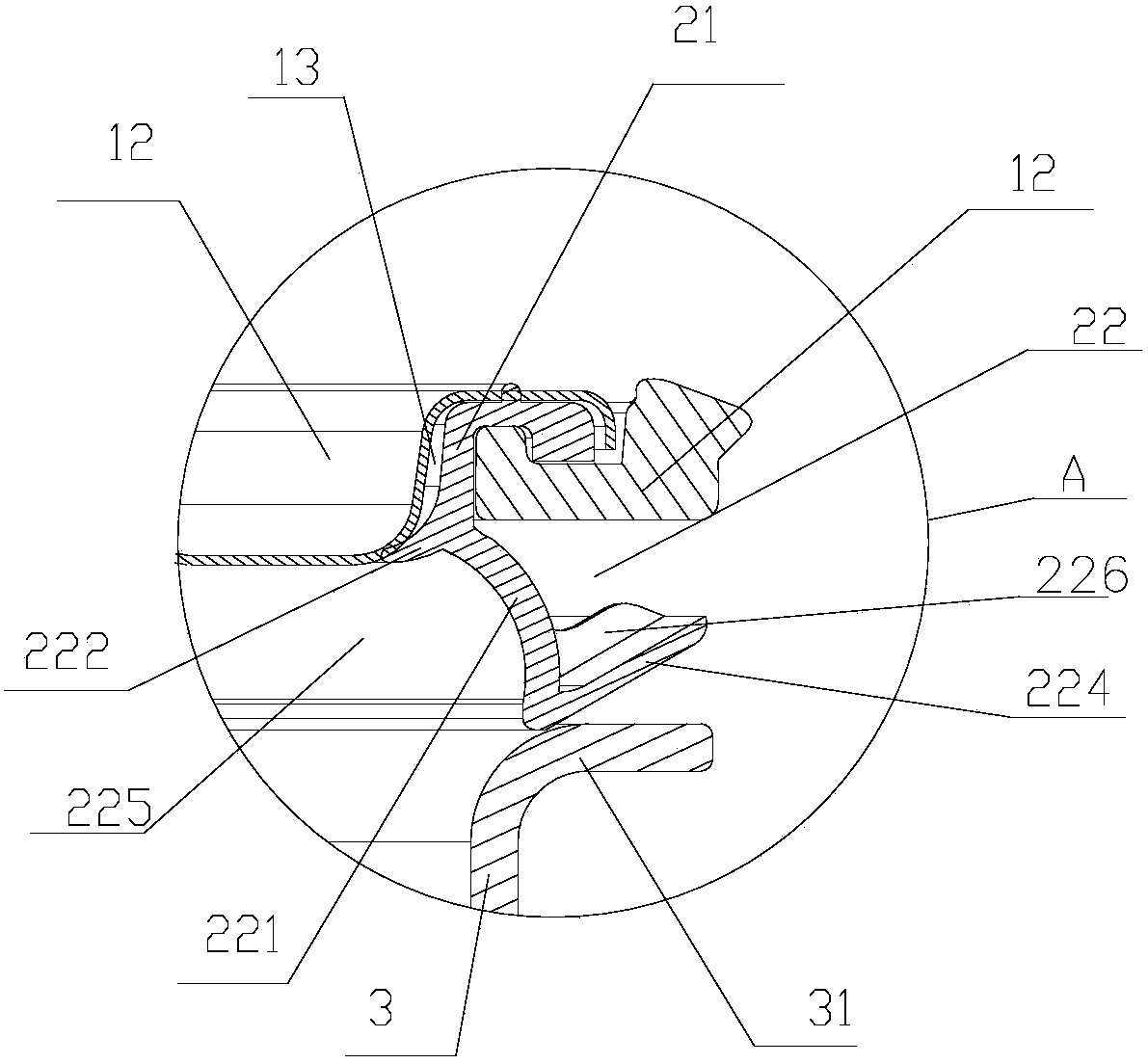

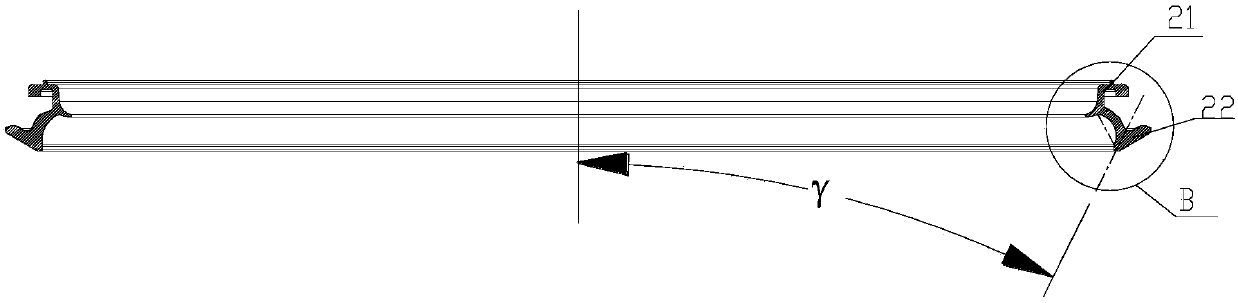

[0042] Such as Figure 1 to Figure 5 As shown, the sealing ring on a cover plate assembly of this embodiment includes an integrally connected installation part 21 and a sealing part 22. On one side of the assembly 1 , the sealing portion 22 extends from one side of the cover assembly 1 in a direction away from the cover assembly 1 ; when the cover assembly 1 is fastened on the cooking vessel 3 , the sealing part 22 abuts on the open edge 31 of the cooking vessel 3 and the side of the sealing part 22 outside the cooking vessel 3 is provided with a reinforcing rib 226 for enhancing the rigidity of the sealing part as a whole, so that the cover plate When the component is fastened to the cooking vessel, the sealing part is not easily deformed after being squeezed, and the sealing effect is better.

[0043] Such as Figure 1 ~ Figure 4As shown, the sealing part 22 preferably adopts a V-shaped structure. The V-shaped structure can be formed by connecting two uniform and smooth ri...

Embodiment 2

[0060] A cover assembly of this embodiment, such as figure 1 As shown, the cover plate assembly 1 includes a cover plate body 12, a ring-shaped pressure plate 11 and a sealing ring 2 as described in Embodiment 1, and the pressure plate 11 is crimped on the peripheral edge of the cover plate body 12 And an annular gap 13 is formed between the cover plate body 12, the mounting part 21 is sealed and crimped in the annular gap 13 and is located on the inner ring side of the pressure plate 11, and the longitudinal section is "Γ" shaped The mounting part 21 is crimped in the annular gap 13, so that the clamping between the mounting part 21 and the pressure plate 11 is firmer; the sealing part 22 extends from the annular gap 13 in a direction away from the cover plate assembly 1 and the annular The gap 13 is sealed and covered. The cover plate assembly of this embodiment is provided with a V-shaped structure sealing ring, and a reinforcing rib is provided on the inner side of the be...

Embodiment 3

[0062] This embodiment provides an upper cover assembly, including a cover body and the cover assembly 1 as described in Embodiment 2, and the other side of the cover assembly 1 is connected to the cover body. In this embodiment, reinforcing ribs are provided on the side of the sealing part located outside the cooking vessel, which enhances the overall rigidity of the sealing part, so that when the cover plate assembly is fastened to the cooking vessel, the sealing part is not easily deformed after being squeezed. The sealing effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com