Novel preparation method of production equipment of nylon coated wire

A nylon-coated wire and production equipment technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as unfavorable water resources protection, non-compliance with environmental protection, etc., and achieve low cost, cost reduction, and economical The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

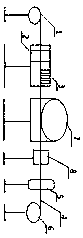

[0013] according to figure 1 Shown, a kind of preparation method of the production equipment of novel nylon coated wire, the production equipment of this novel nylon coated wire comprises pay-off frame 1, grinder, coating machine 7, extruder 8, traction roller 5 and take-up Machine 6.

[0014] Further, the grinding machine includes a grinding stone 2 and a cloth 3 , the grinding stone 2 and the cloth 3 are on an assembly line, the grinding stone 2 is divided into upper and lower parts, and the grinding stone 2 is at the front end of the cloth 3 .

[0015] Further, the grinding stone 2 is massive sandstone, quartz or granite.

[0016] Further, the cloth 3 is waste clothes cloth 3 and the like.

[0017] Further, the pay-off frame 1, grinder, coating machine 7, extrusion machine 8, traction roller 5 and wire take-up machine 6 are arranged in sequence on the same horizontal plane.

[0018] During the production process of the nylon coated wire, the iron wire 4 is released from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com