Automatic processing and recovering robot for waste aluminium profiles produced during aluminium alloy machining

An automatic processing, aluminum alloy technology, applied in the direction of solid waste removal, etc., can solve the problems of long time consumption, high labor intensity, wasted labor, etc., and achieve the effect of improving efficiency, improving accuracy and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

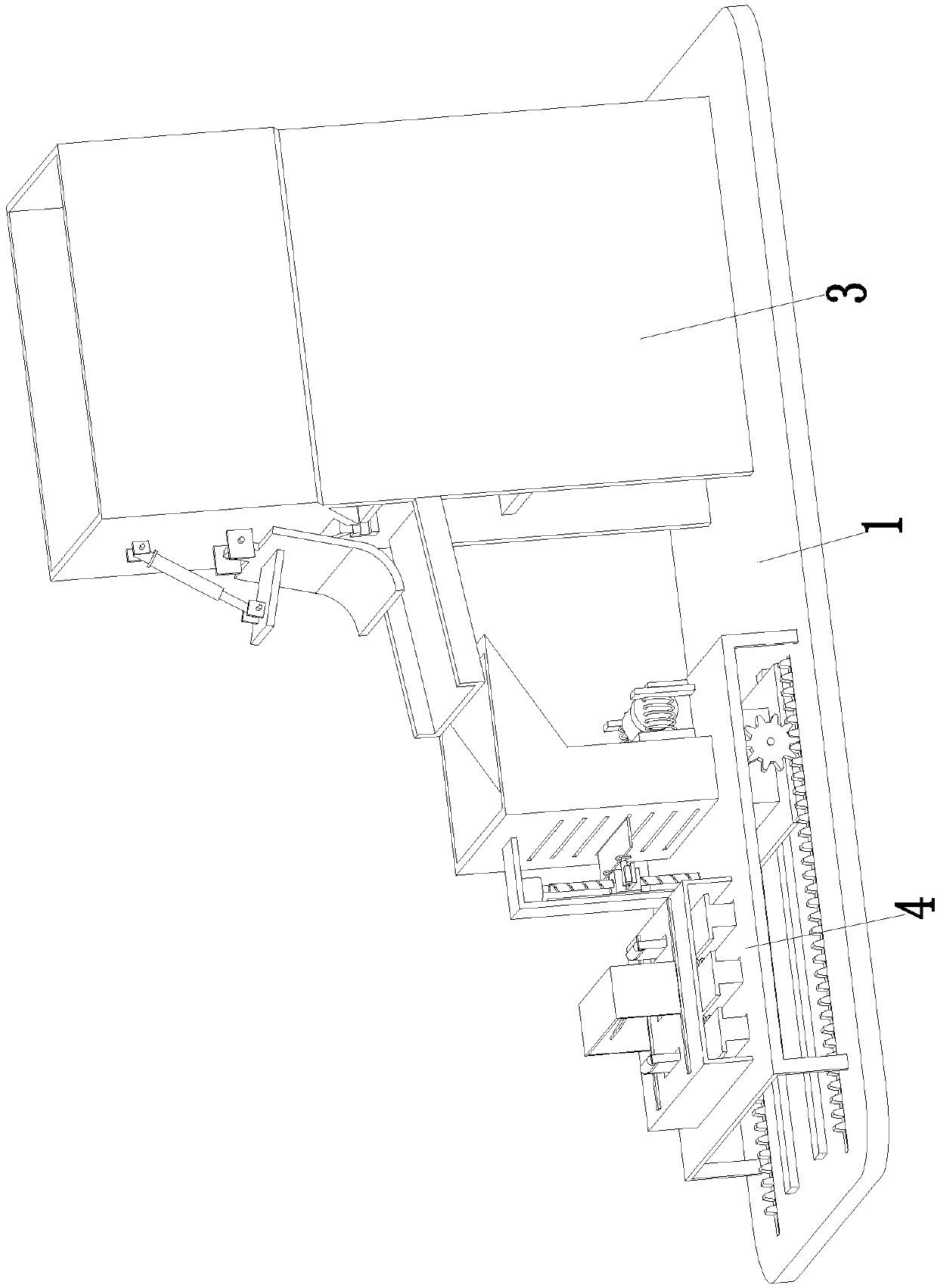

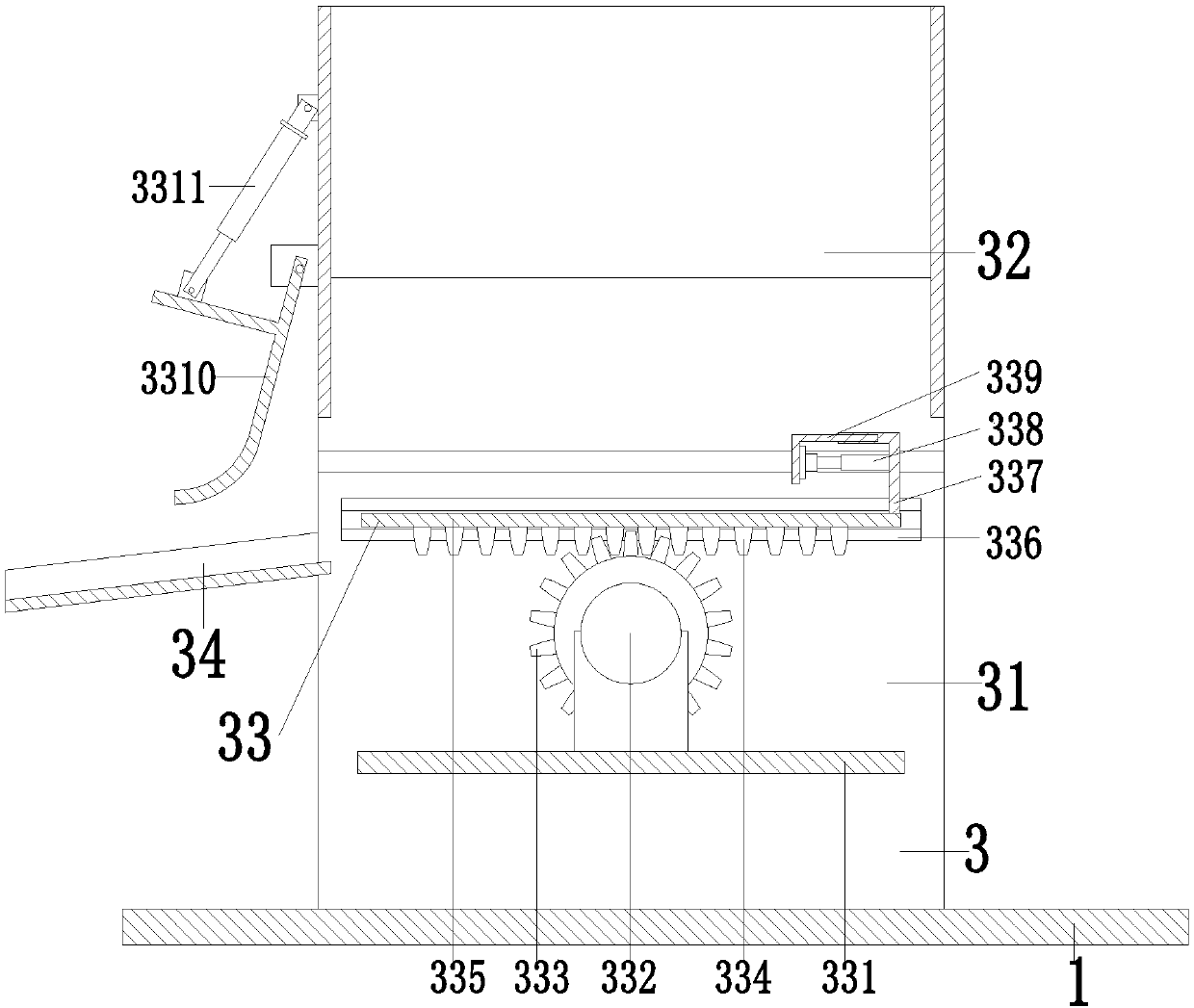

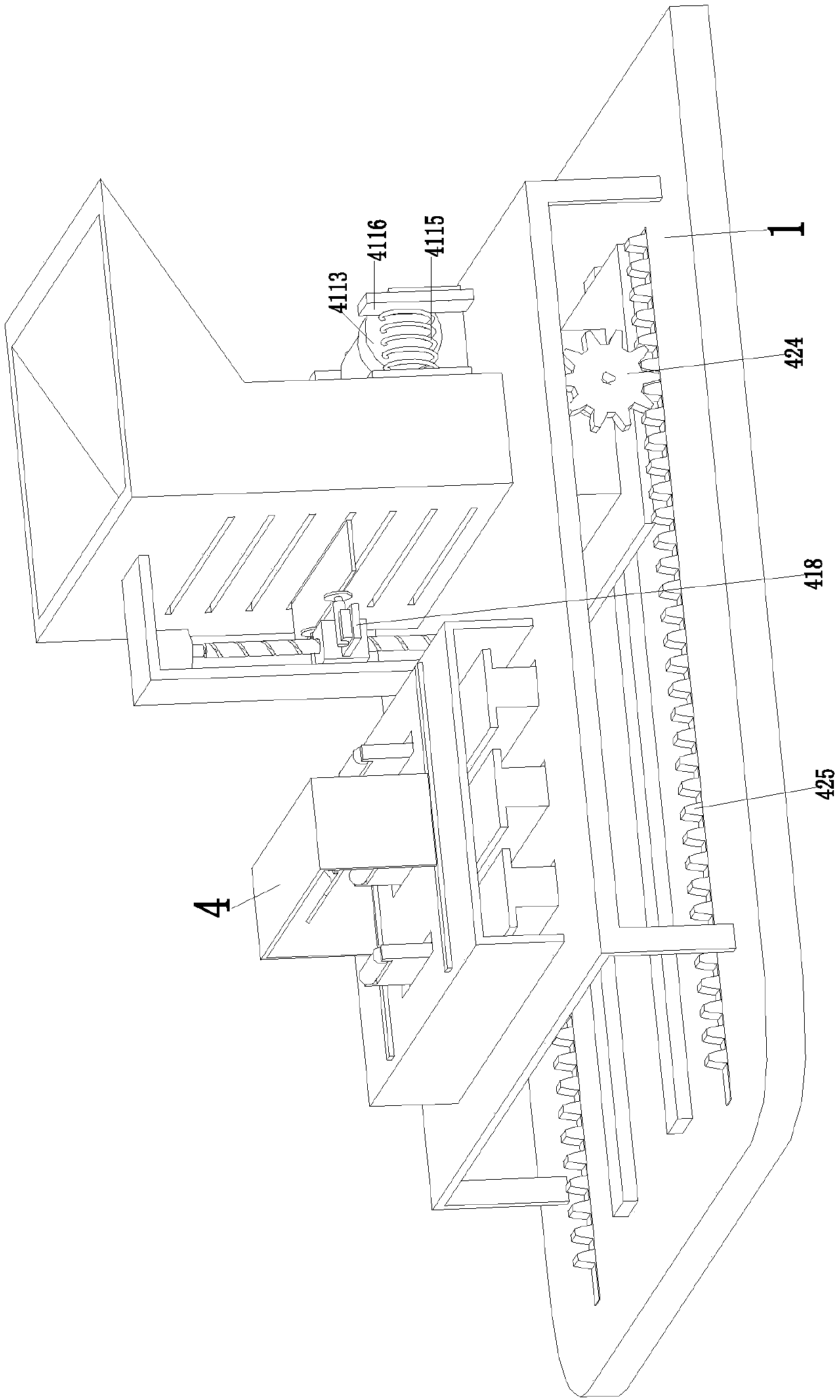

[0024] Such as Figure 1 to Figure 5 As shown, an automatic processing and recycling robot for aluminum waste profiles produced by aluminum alloy processing, including a base plate 1, on which a limiting device 3 and a flattening device 4 are installed in sequence from front to back, and the limiting device 3 can control the aluminum profiles. The processing quantity, the crushing device 4 can be used for beating aluminum profiles, and the limiting device 3 and the crushing device 4 are used in conjunction with each other to complete the process of automatic processing of waste aluminum profiles.

[0025] The limiting device 3 includes a limiting frame 32 installed on the base plate 1 by two limiting support frames 31, a limiting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com