Anti-fracture water-cooling automatic water-removing wire-winding metal drawing machine equipment

A water-cooled, anti-fracture technology, applied in progressive dryers, lighting and heating equipment, dryers, etc., can solve problems such as product corrosion, broken metal wires, and easy sticking of water vapor to avoid rust and ensure drying , The effect of guaranteeing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

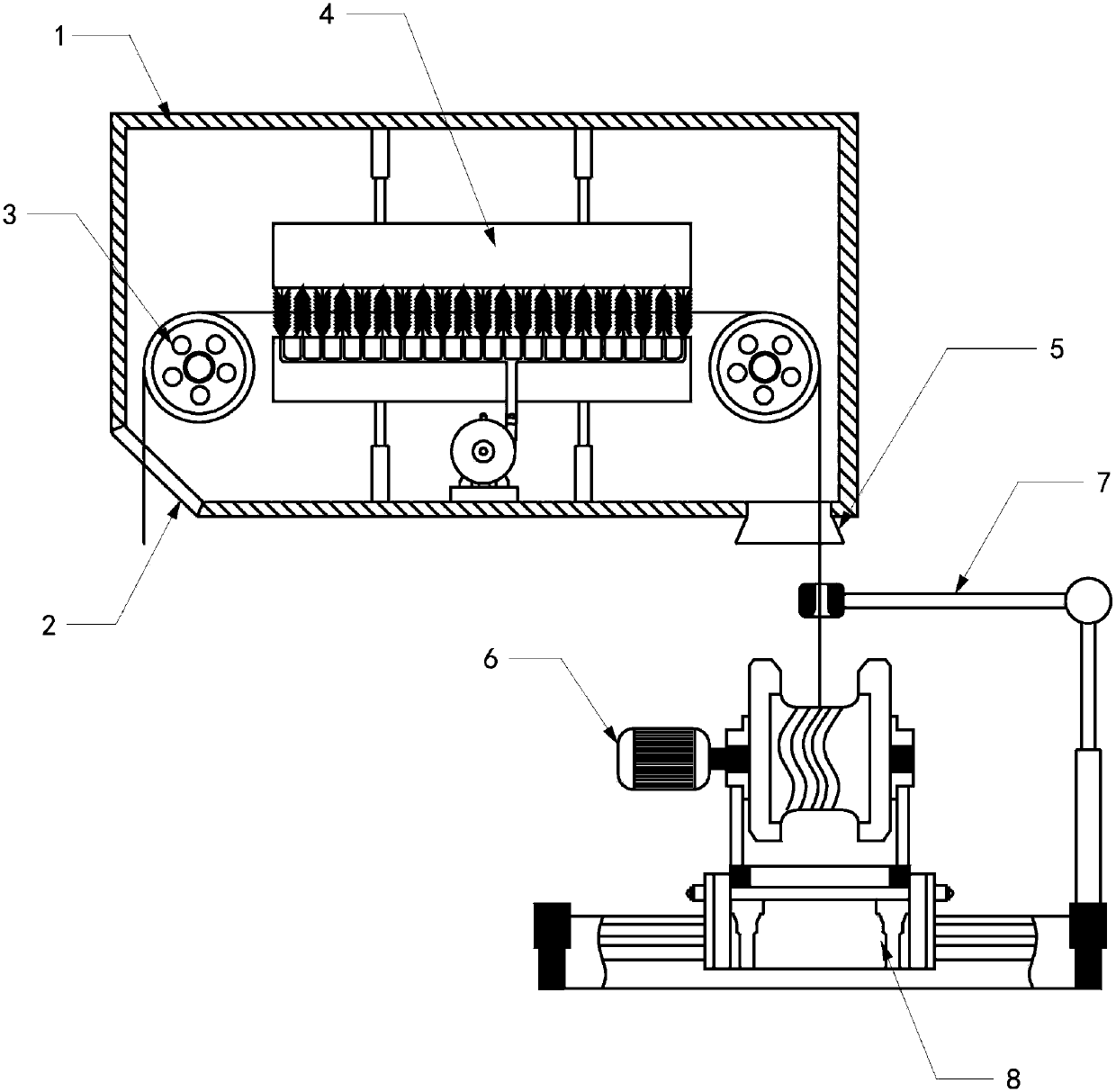

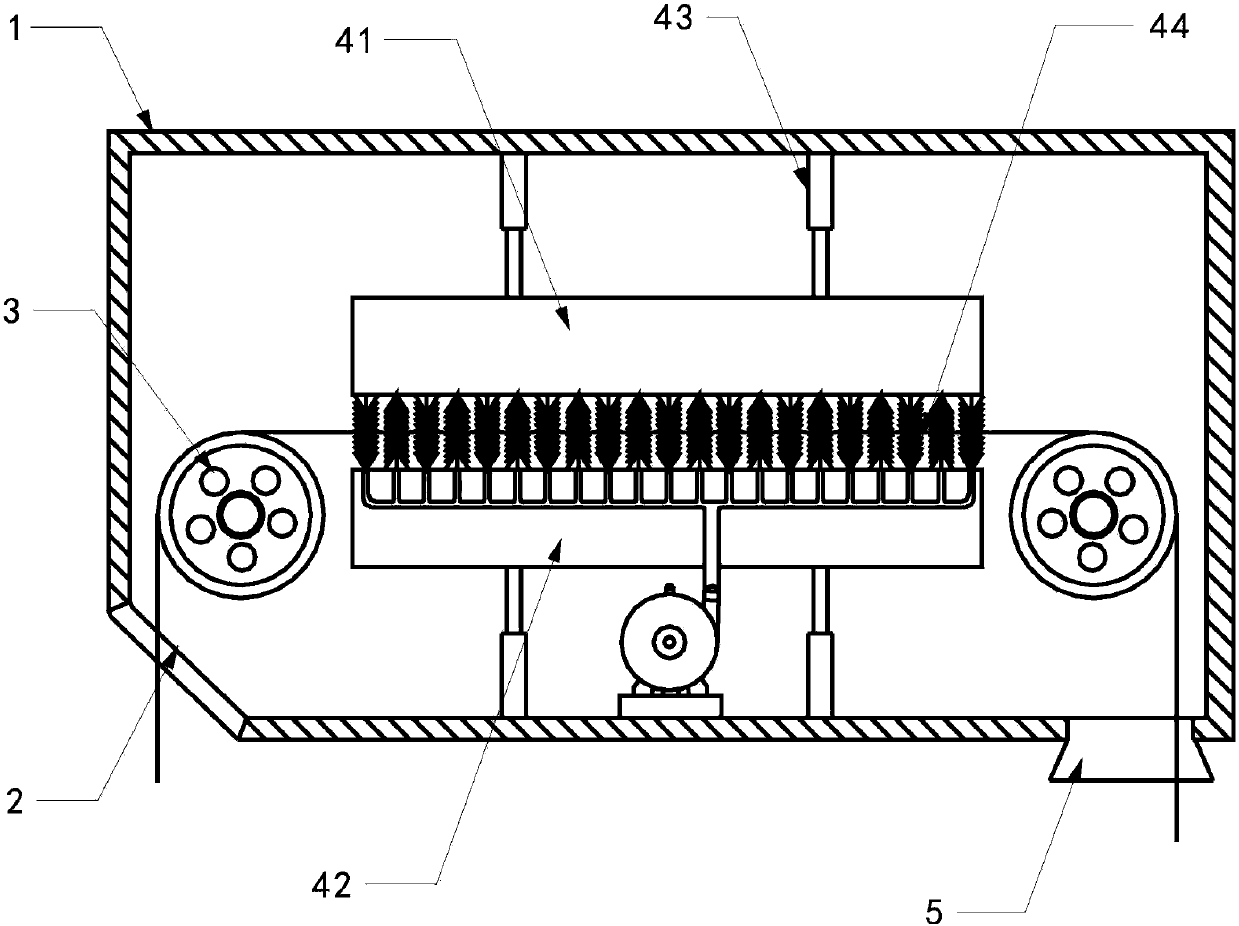

[0022] As shown in the figure, this embodiment provides an anti-breakage water-cooled automatic dewatering winding metal wire drawing machine equipment, which includes a housing 1, and the lower end of the housing 1 is provided with a through hole 2 for the metal wire to enter, and also includes The guide runner 3, the drying mechanism 4 for cleaning the surface moisture of the metal wire, and the wire outlet 5 arranged in sequence in the housing 1, the drying mechanism 4 is connected with the upper and lower walls of the housing 1, and the wire outlet 5 is arranged on the the tail of the casing 1;

[0023] It also includes a winding mechanism 6 for winding the wire, a limit mechanism 7 for limiting the swing range of the wire, and a displacement mechanism 8 for controlling the horizontal movement of the winding mechanism 6. The winding mechanism 6 is installed on the Below the wire outlet 5 , the winding mechanism 6 is fixed on the displacement mechanism 8 , and the limiting ...

Embodiment 2

[0027] In this embodiment, the following optimizations are made on the basis of Embodiment 1: the central axes of the first limiting block 41 and the second limiting block 42 of this embodiment are provided with semicircular grooves 45 for the passage of metal wires , the water-absorbing cotton brushes 44 are uniformly distributed in the semicircular groove 45 radially.

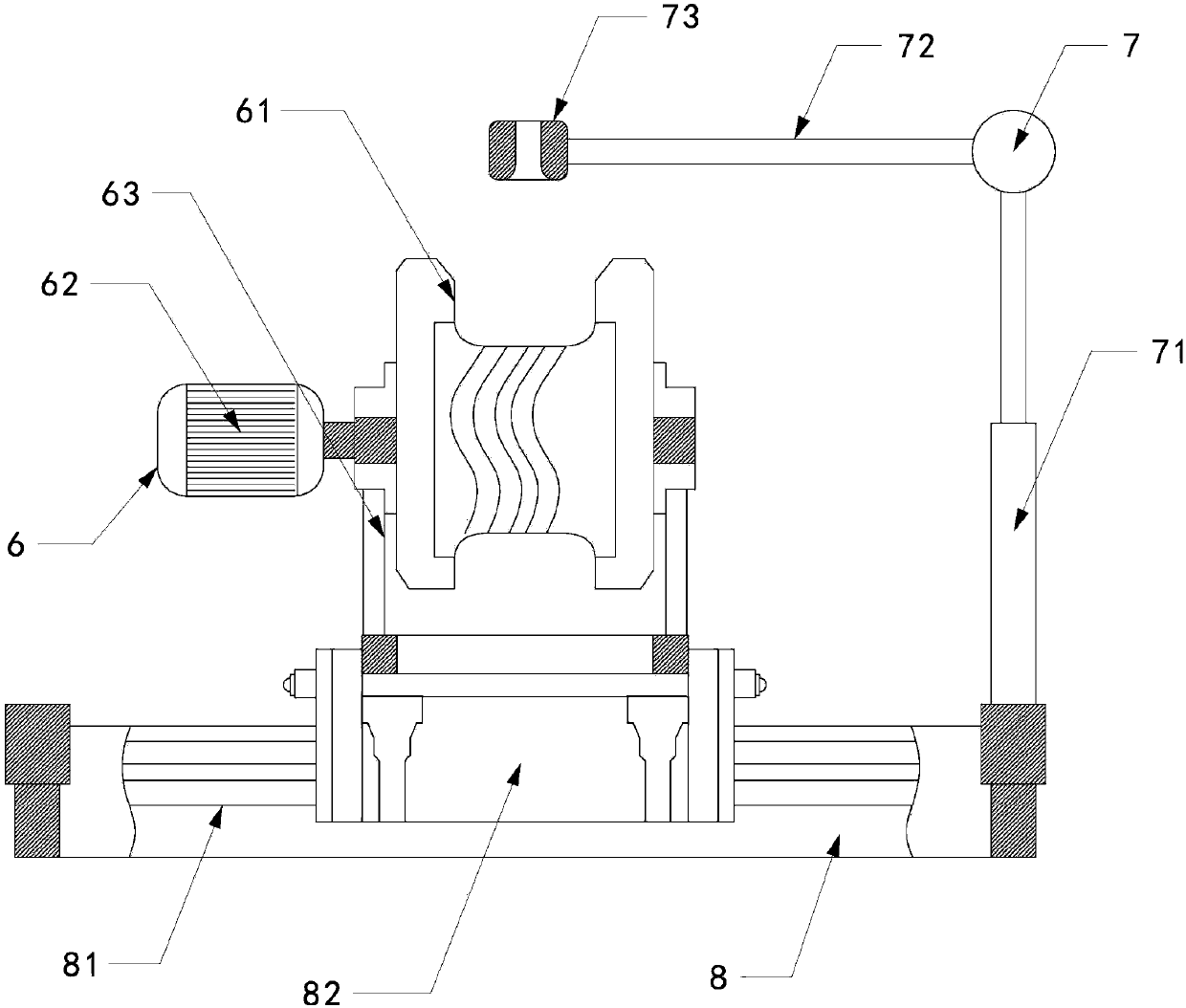

[0028] Further, the winding mechanism 6 of this embodiment includes a wire passing wheel 61, a winding motor 62, and a conversion bracket 63, and the wire passing wheel 61 is installed on the displacement mechanism 8 through the conversion bracket 63, and the winding motor 62 The output end meshes with the connecting end of the wire passing wheel 61; the wire passing wheel 61 includes a fixed shell and a rotating inner core, the rotating inner core is connected with the winding motor 62 through a rotating shaft, and the fixed shell is moved by the conversion bracket 63 and the displacement mechanism 8 Compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com