Drill coping device

A drill bit and drill bit fixture technology, which is used in drilling tool accessories, grinding workpiece supports, drilling/drilling equipment, etc., can solve the problems of damaged drill bits, excessive grinding, and high manufacturing costs, avoiding safety accidents and reducing The effect of low grinding amount and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

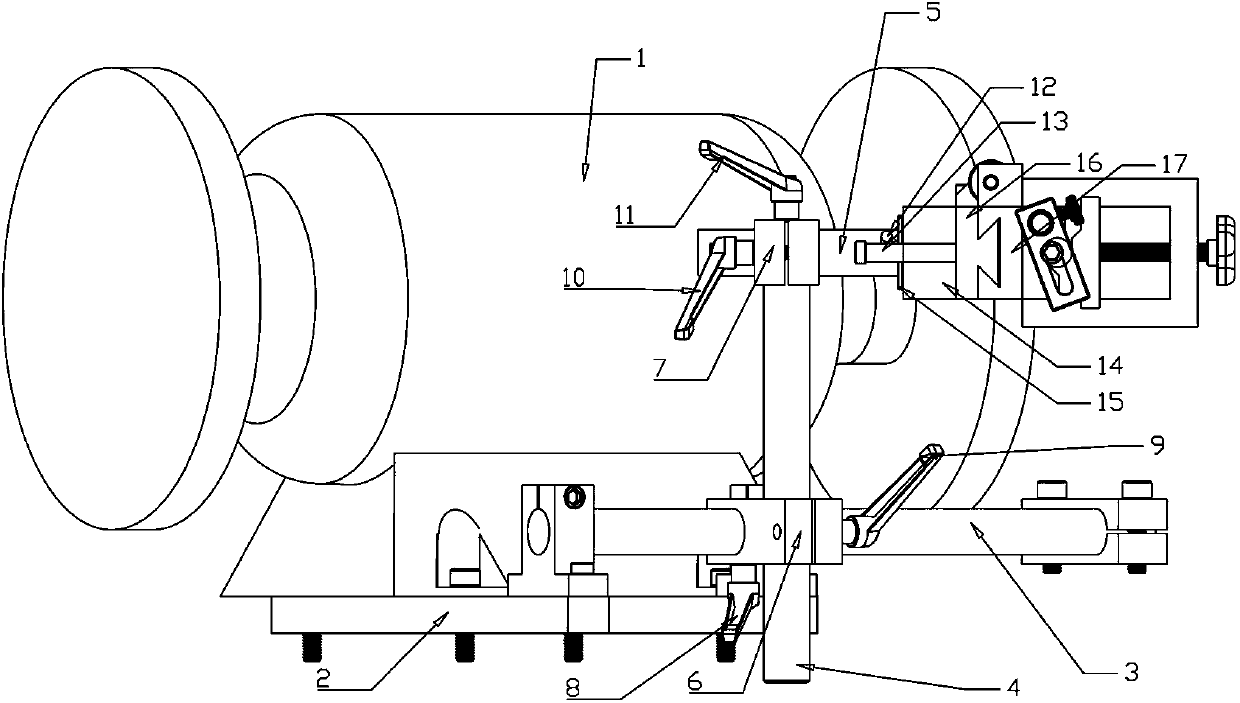

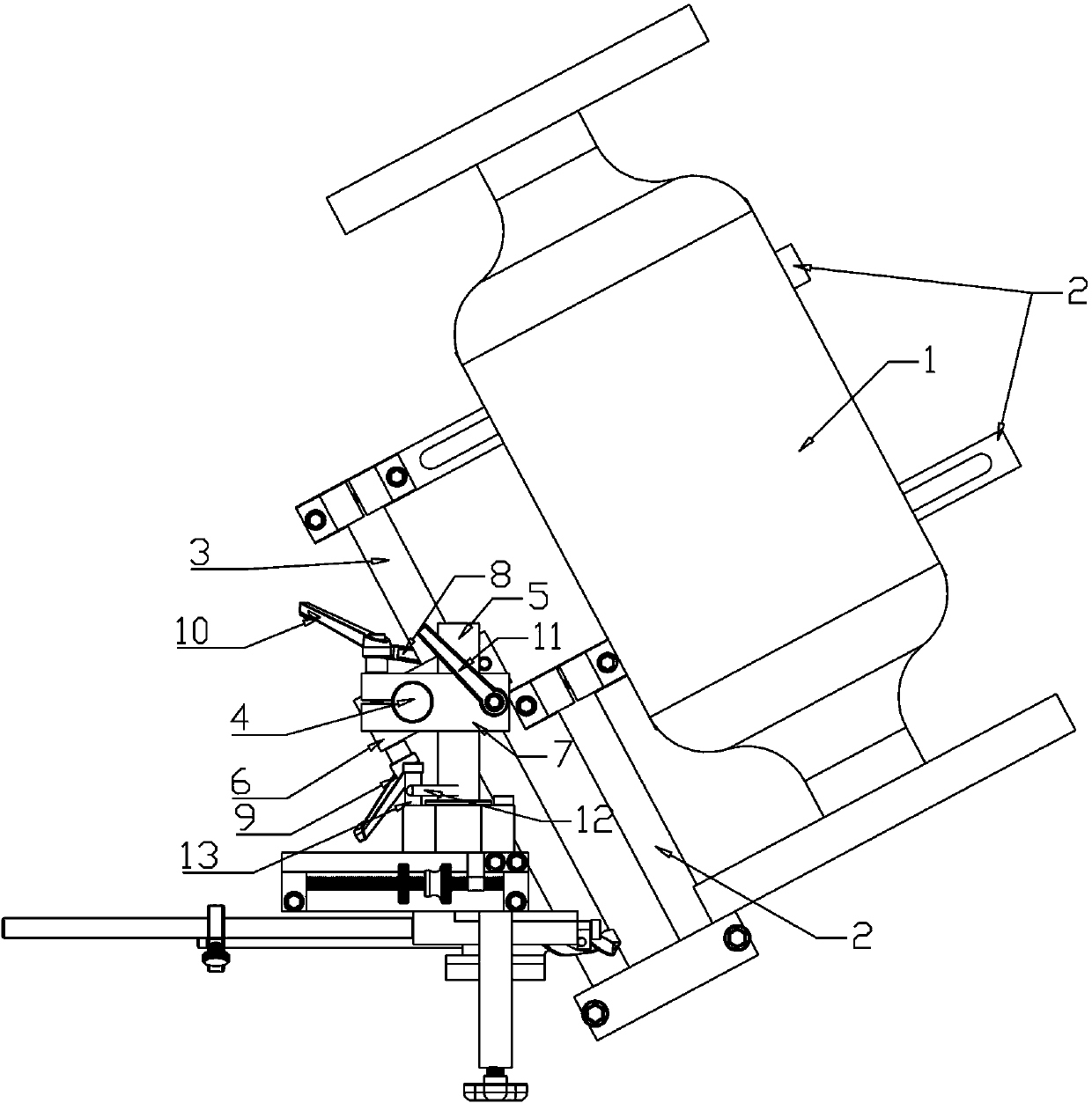

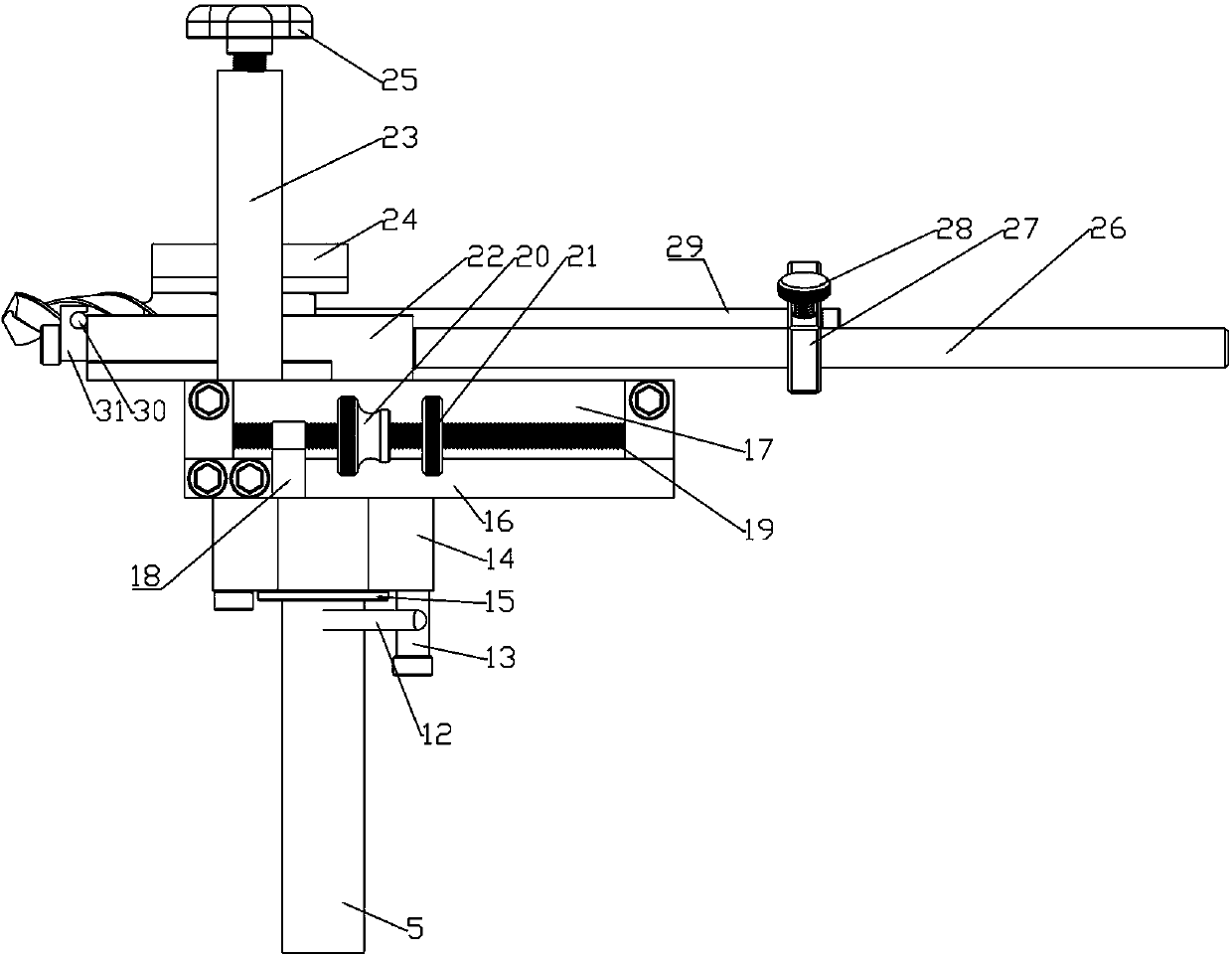

[0032] refer to Figure 1-12 As shown, the drill bit grinding device of the present invention comprises a bracket 2, a slide rail 3, a column 4, a main shaft 5, a slider assembly and a drill bit fixture. One end of the bracket 2 is connected to the grinder 1, and the opposite end is connected to the slide rail 3. The slide rail 3, the column 4 and the main shaft 5 are respectively connected by connecting blocks. The connecting blocks are provided with fasteners. By adjusting the tightness of the fasteners, the slide rail 3, the column 4 and the main shaft 5 are connected The relative position can be adjusted between them, the main shaft 5 is connected through the bearing 15, the bearing seat 14 and the slider base 16 in the slider assembly, the drill bit fixture is fixed on the slider 17 in the slider assembly, and follows the The slider assembly rotates. The connecting block is preferably a cross connecting block (the connecting block has a cross-shaped mounting hole), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com