Automatic rust removing machine for steel rails

A technology for derusting machines and rails, applied in the direction of grinding drive devices, grinding machine parts, grinding machines, etc., can solve problems such as difficult implementation, rail wear loss, and reduced reliability of machine tools, so as to achieve simple and reliable structure, The effect of high rust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

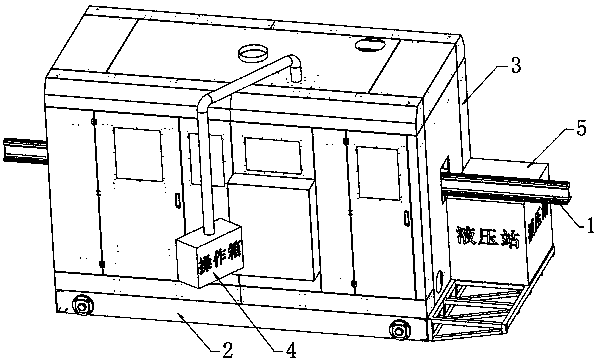

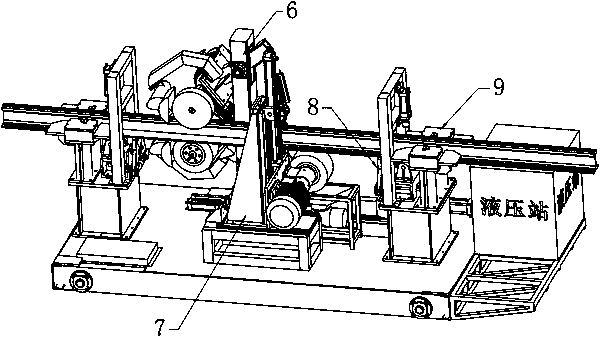

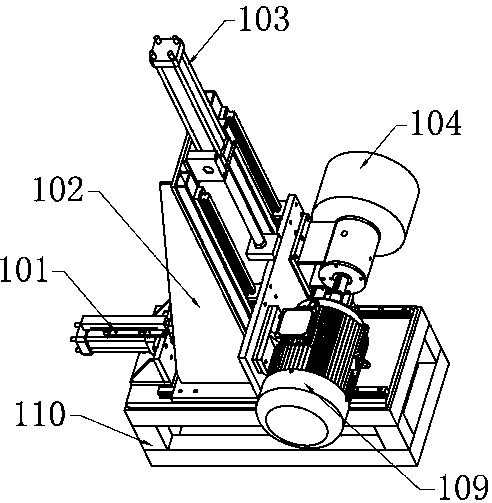

[0026] An automatic derusting machine for rails comprises a base trolley 2, the base trolley 2 is provided with an integral cover 3 of the derusting machine, the steel rail 1 to be derusted passes through the integral cover 3 of the derusting machine, and the integral cover of the derusting machine 3 There are rail top and rail bottom derusting devices 6, end surface derusting devices 7, clamping and centering positioning devices 8 and rail guide devices 9, and two rail guide devices 9 are arranged on the rail 1 to be derusted, and each rail The inner side of the guide device 9 is provided with a tightening and centering positioning device, and a rail top and rail bottom derusting device 6 and an end surface derusting device 7 are provided between the two clamping and centering positioning devices 8 . The rail top and rail bottom derusting device 6 of the present invention can automatically judge the position of the base metal of the rail through the current feedback of the fla...

Embodiment 2

[0028] An automatic derusting machine for rails, characterized in that it includes a base trolley 2, the base trolley 2 is provided with an overall cover 3 of the derusting machine, the steel rail 1 to be derusted passes through the overall cover 3 of the derusting machine, the The overall cover 3 of the derusting machine is equipped with a rail top and rail bottom derusting device 6, an end surface derusting device 7, a clamping and centering positioning device 8 and a rail guide device 9, and two rail guide devices are arranged on the rail 1 to be derusted 9. A tightening and centering positioning device is provided on the inner side of each rail guide device 9, and a rail top and rail bottom derusting device 6 and an end surface derusting device 7 are provided between the two clamping and centering positioning devices 8.

[0029] The end surface derusting device 7 and the rail top and rail bottom derusting device 6 are arranged separately on the base trolley 2 one after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com