6R robot inverse kinematic geometry solving method based on screw theory

A technology of robot kinematics and inverse kinematics, applied in manipulators, complex mathematical operations, program-controlled manipulators, etc., and can solve problems such as inapplicability to six-degree-of-freedom robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

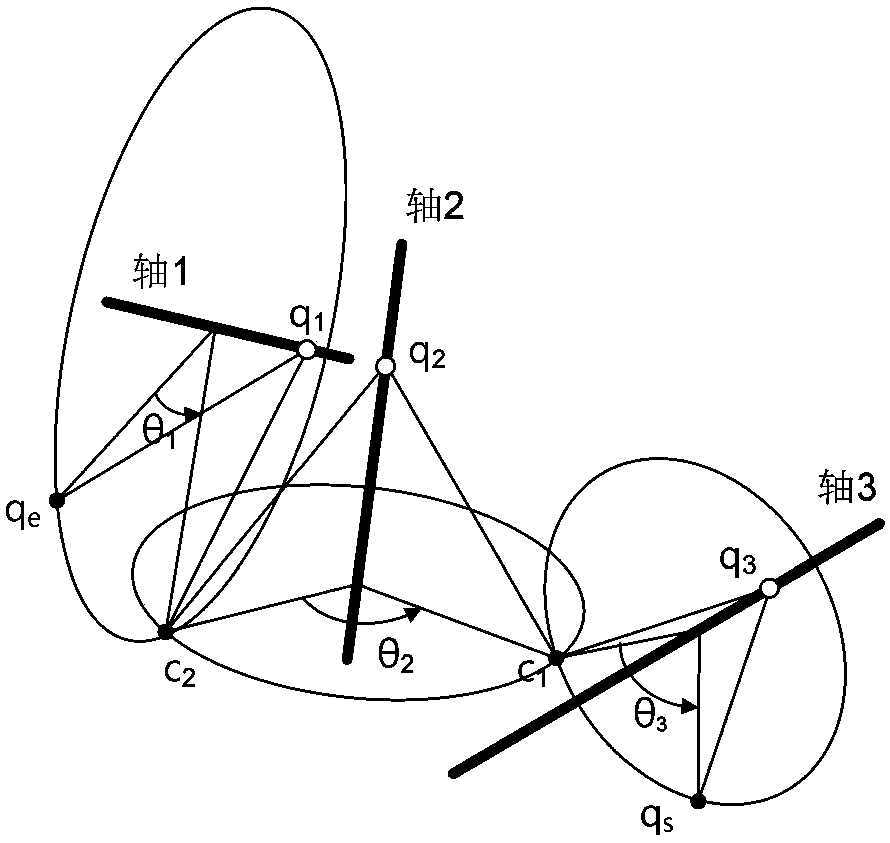

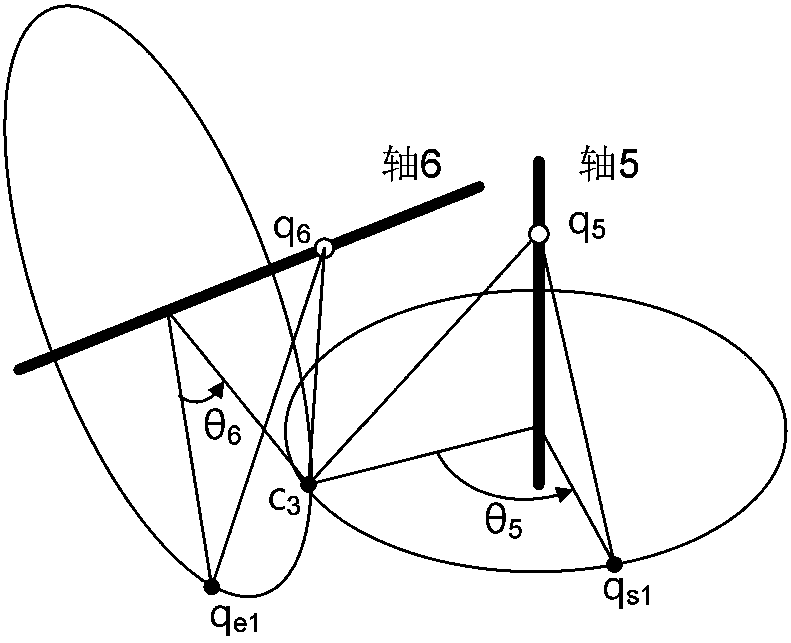

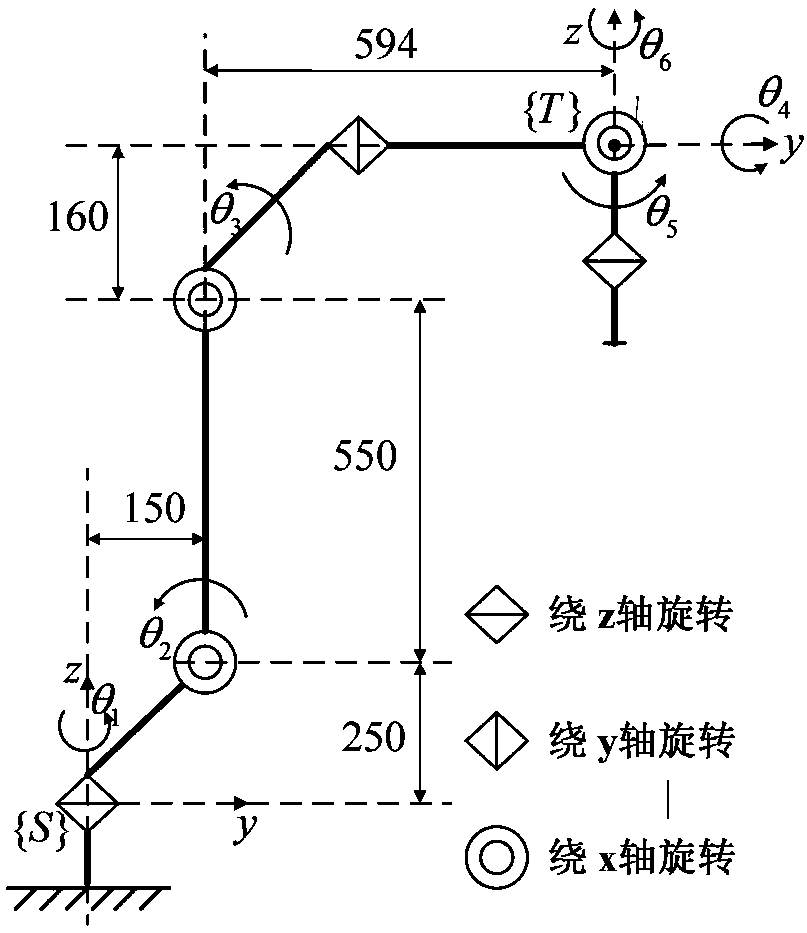

[0017] The following is attached Figure 1-3 The present invention will be described in detail.

[0018] S1 determines the kinematics parameters of the 6R robot and establishes a positive kinematics model

[0019] Such as image 3 As shown, the position vector and rotation vector of each joint in the known initial state of the 6R robot are as follows:

[0020]

[0021]

[0022] where r i , 1≤i≤6 means the position vector of joint i in the base coordinate system, ω i Indicates the rotation vector of the i joint.

[0023] Based on the screw theory, the forward kinematics model of the 6R robot is expressed as,

[0024]

[0025] where g st (θ), g st (0) respectively represent the initial pose and target pose of the robot end, Indicates the exponential product form of the rotation motion of the i joint,

[0026]

[0027] where θ i is the i-th joint angular displacement; is the i joint rotation vector ω i Another form of representation, by ω i =[ω 1 ω 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com