Disc type vibrating stirring machine

A mixer and disc technology, which is applied in the field of disc vibration mixers, can solve the problem of not reaching uniformity, and achieve the effects of increasing the number of effective collisions, shortening the mixing time, and enhancing the interface bond strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

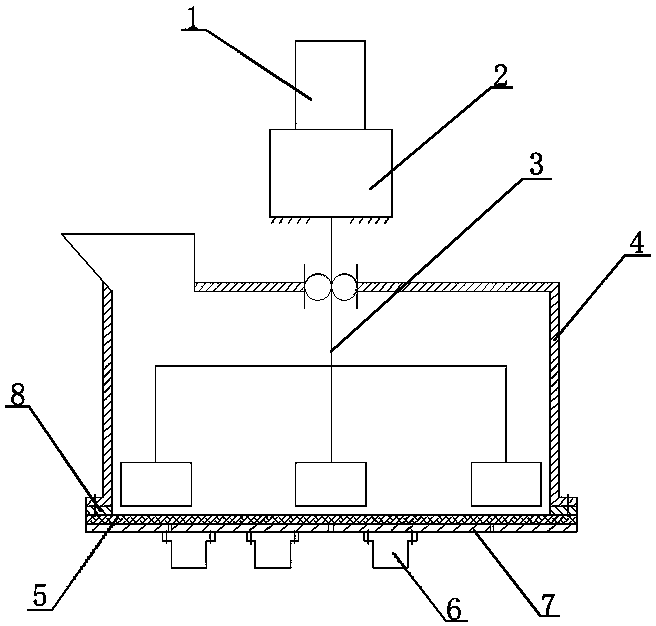

[0027] Such as figure 1 with 5 As shown, a disc vibrating mixer includes a mixing tank, a power unit and a mixing unit, the power unit is arranged above the mixing tank, the power unit includes a drive motor 1 and a reducer 2, the output shaft of the drive motor 1 and the reducer 2 The output shaft of the reducer 2 is connected to the upper end of the stirring shaft 3, and the lower end of the stirring shaft 3 extends into the mixing tank and is connected with the stirring assembly. The stirring assembly is composed of a stirring arm and a stirring blade, and the stirring arm is fixedly connected to the stirring shaft 3. The stirring blade is fixedly connected to the stirring arm, the mixing cylinder is composed of an upper cylinder body 4 and a lower cylinder body 5, the lower cylinder body 5 is a flexible plate body, the flexible plate body is a rubber plate or a polyurethane plate, and the lower cylinder body 5 is connected with the upper cylinder body The cylinder blocks ...

Embodiment 2

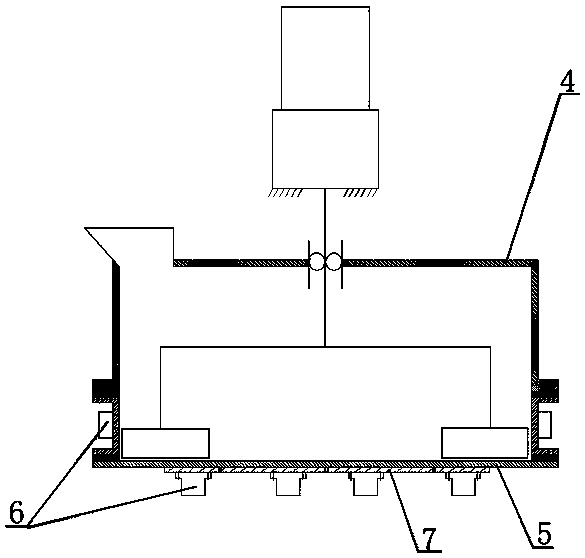

[0030] Such as figure 2 As shown, a disc vibrating mixer includes a mixing tank, a power unit and a mixing unit, the power unit is arranged above the mixing tank, the power unit includes a drive motor 1 and a reducer 2, the output shaft of the drive motor 1 and the reducer 2 The output shaft of the reducer 2 is connected to the upper end of the stirring shaft 3, and the lower end of the stirring shaft 3 extends into the mixing tank and is connected with the stirring assembly. The stirring assembly is composed of a stirring arm and a stirring blade, and the stirring arm is fixedly connected to the stirring shaft 3. The stirring blade is fixedly connected to the stirring arm, and the mixing cylinder is composed of an upper cylinder body 4 and a lower cylinder body 5, and the upper cylinder body 4 is composed of an upper cylinder body and a lower cylinder body, and the upper cylinder body and the lower cylinder body Connected by elastic elements, the lower cylinder body and the ...

Embodiment 3

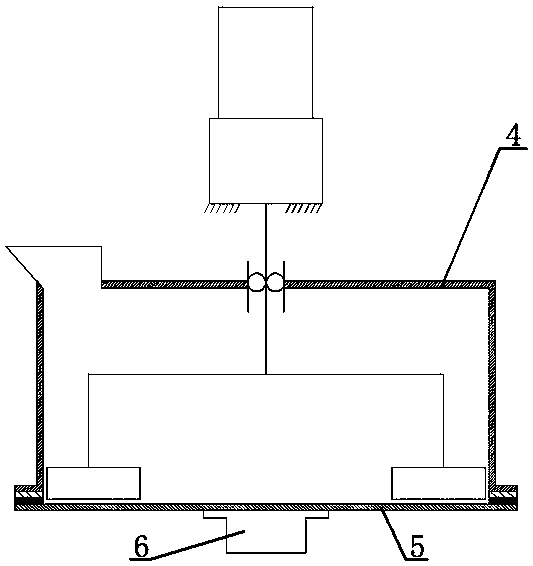

[0033] Such as image 3 As shown, a disc vibrating mixer includes a mixing tank, a power unit and a mixing unit, the power unit is arranged above the mixing tank, the power unit includes a drive motor 1 and a reducer 2, the output shaft of the drive motor 1 and the reducer 2 The output shaft of the reducer 2 is connected to the upper end of the stirring shaft 3, and the lower end of the stirring shaft 3 extends into the mixing tank and is connected with the stirring assembly. The stirring assembly is composed of a stirring arm and a stirring blade, and the stirring arm is fixedly connected to the stirring shaft 3. The stirring blade is fixedly connected to the stirring arm. The mixing cylinder is composed of an upper cylinder body 4 and a lower cylinder body 5. The lower cylinder body 5 is a rigid plate structure, and the lower port of the upper cylinder body 4 has a flange extending outward. , an elastic element is arranged between the flange of the upper cylinder 4 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com