Screen printing machine achieving low-temperature curing

A screen printing machine, low-temperature technology, applied in the field of low-temperature curing screen printing machines, can solve the problems of low degree of automation, long time consumption, high energy consumption, and achieve the effects of no potential safety hazards, improved production efficiency, and low curing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

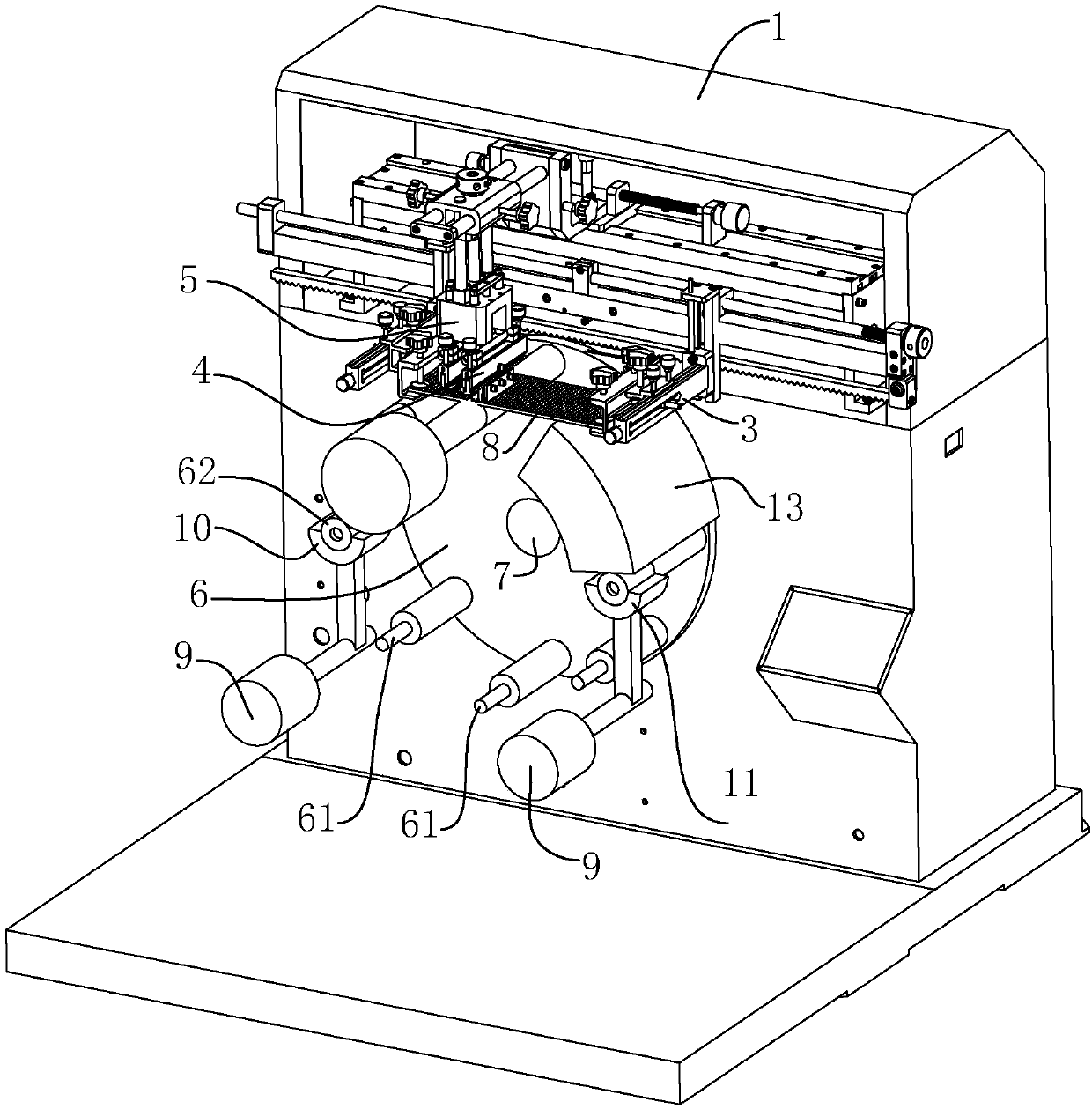

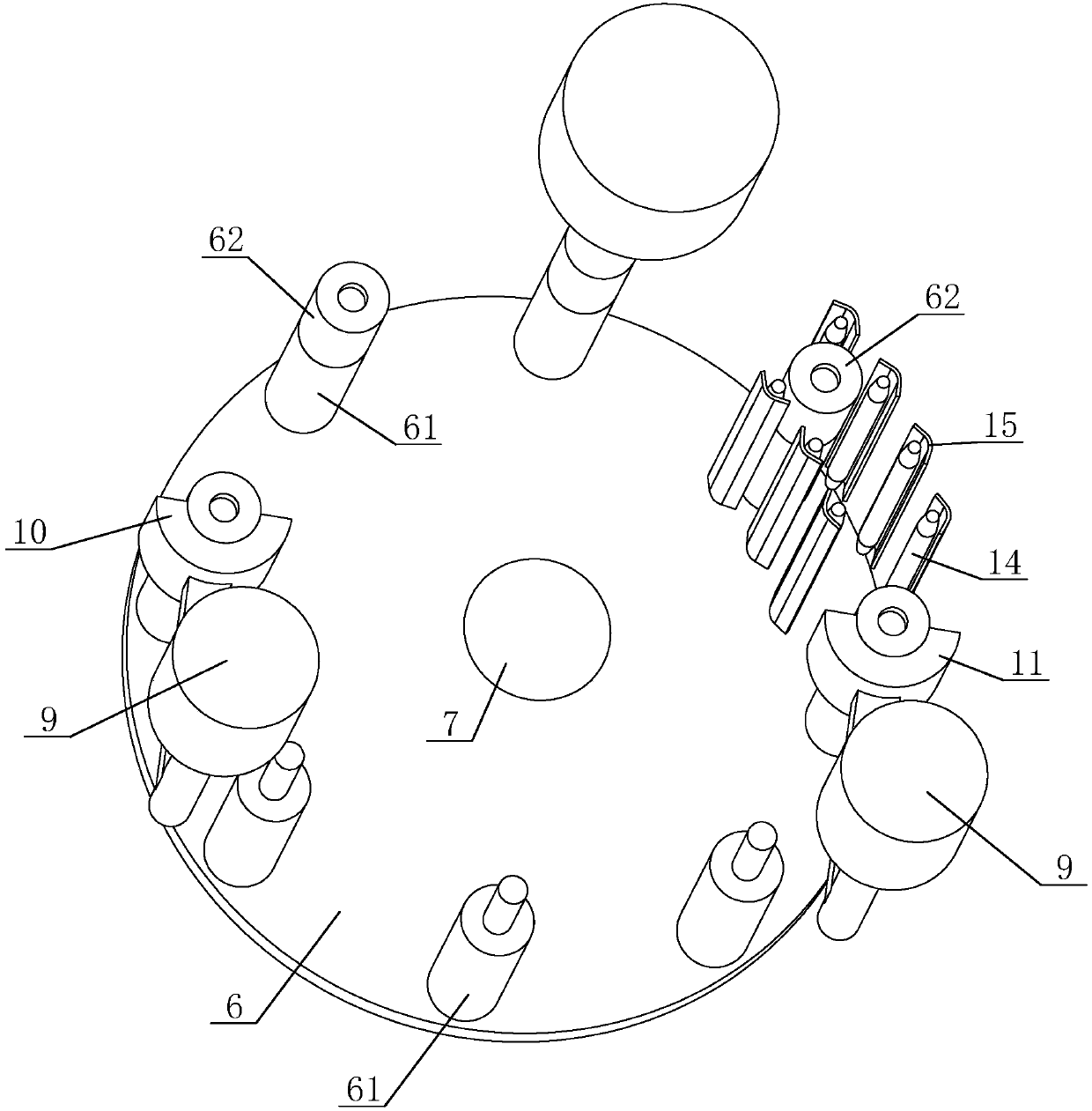

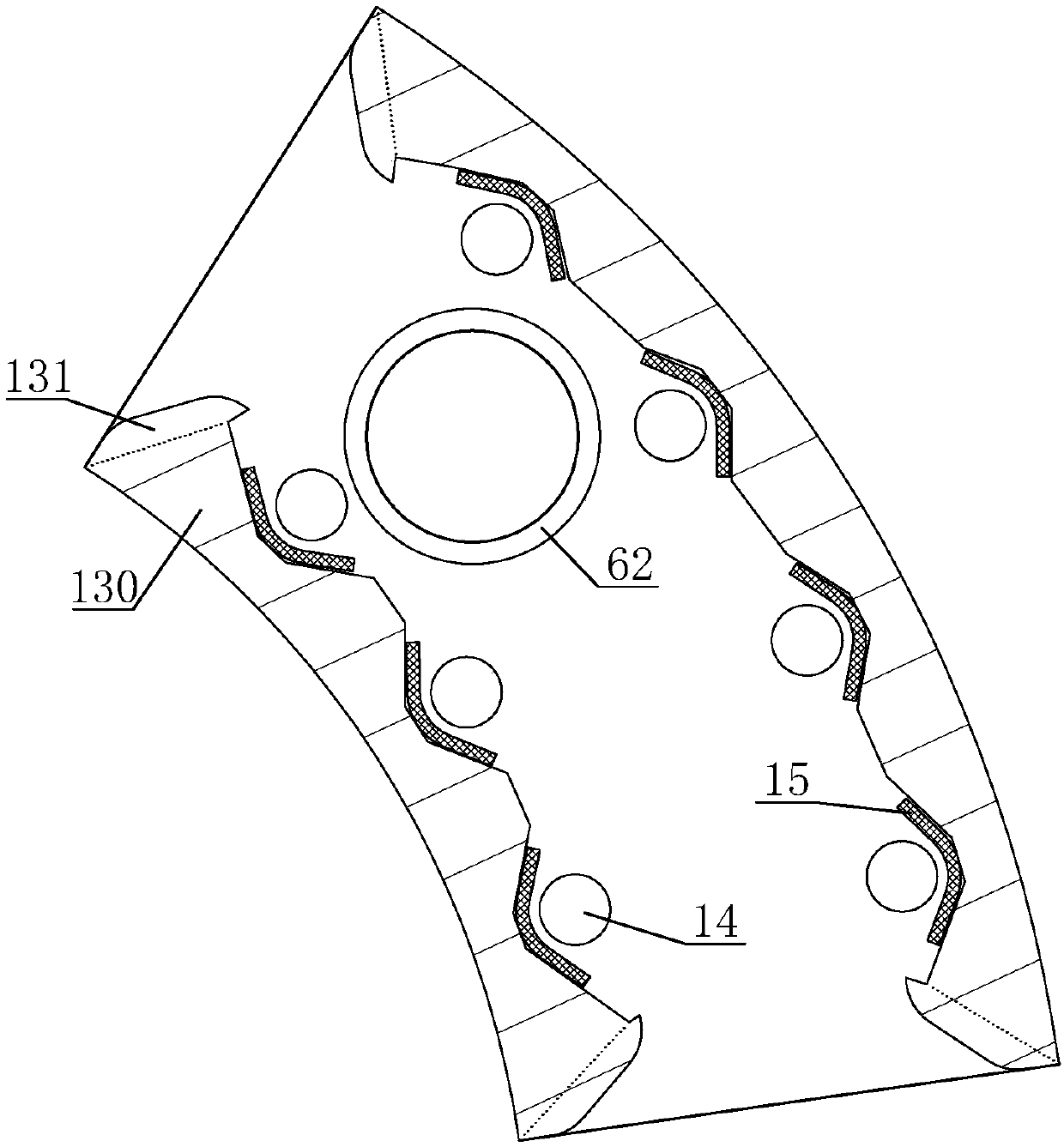

[0026] Such as Figures 1 to 3 The shown low-temperature curing screen printing machine includes a frame 1, and a screen printing device, a printing plate device, a conveying device, a pressing device 12 and a curing device installed on the frame 1.

[0027] The printing plate device includes a first driving member, a horizontal slide rail 2 fixed on the frame 1, a screen clamping mechanism 3 installed on the horizontal slide rail, and a screen 8 fixed on the screen clamping mechanism. The first driving member drives the screen clamping mechanism to reciprocate along the horizontal slide rail 2 and drives the screen 8 to reciprocate.

[0028] The screen printing device includes a screen printing device including an inking mechanism that delivers ink to the screen 8, a scraper 4 installed perpendicular to the screen 8, and a second driving member 5 that drives the scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com