Warp-knitting elastic fabric weaving method achieving double-sided yin-yang jacquard effect

An elastic fabric and double-sided technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as not meeting the development requirements of an innovative society, increasing production costs, and environmental protection issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

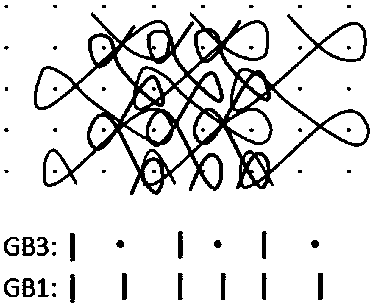

[0024] A method for weaving a warp-knitted elastic fabric with a double-sided yin-yang jacquard effect, comprising the following steps:

[0025] (1) Use the warp knitting design software for pattern design; specifically, use the warp knitting design software for pattern design to determine the different organizational structures of the jacquard area by filling in different colors on the design software, so that the A design pattern is formed on the fabric.

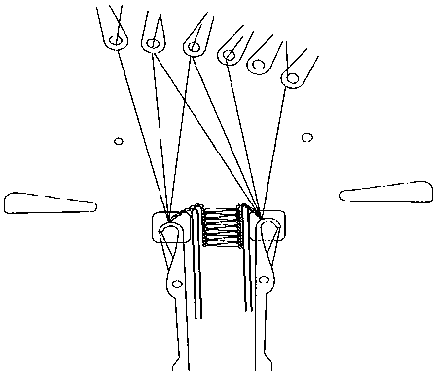

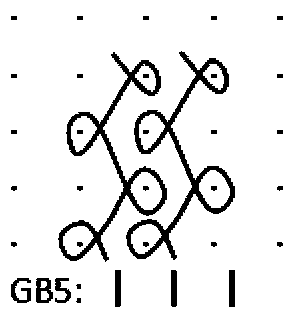

[0026] (2) Determine the weaving process conditions; specifically, the weaving process includes the following: using 5 bars GB1, GB2, JB4-1, JB4-2, and GB5 of the RDJ5 / 1 warp knitting machine to weave, and using different combs Different yarns and yarn threading methods are inserted into the bar to weave with different structures.

[0027] (3) Determine the yarn type and bar threading method used in the fabric weaving process according to the pattern effect and application range; specifically, the yarn types used in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com