Novel workbench used for edge covering process during carpet processing

A workbench and carpet technology, which is applied in the field of workbenches used in the hemming process of new carpet processing, can solve the problems of affecting the quality and effect of hemming, inconvenient movement, heavy weight, etc., to improve utilization efficiency, avoid airflow concentration, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the drawings and embodiments:

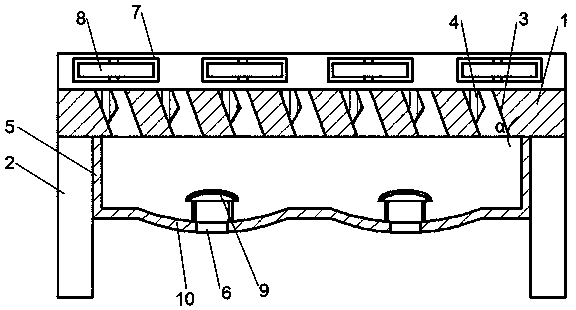

[0025] Such as figure 1 As shown, a new type of workbench for the edging process of carpet processing includes a table 1 on which carpets are placed. The lower end of the table 1 is provided with a support pillar 2 and an air guide hole 3 is formed in the table 1 and the air guide hole 3 Inclined to the direction in which the carpet moves, the air guide hole 3 has a rectangular cross section, a flow increasing block 4 is arranged on the upper part of the inner wall of the air guide hole 3, and an air storage chamber 5 connected to the air guide hole 3 is arranged below the table 1, An interface 6 communicating with the air pump is formed in the bottom wall of the air storage chamber 5, an arc-shaped buckle cover 9 with an opening facing the interface 6 is provided above the interface 6, and the lower wall of the air storage chamber 5 forms an arc-shaped The gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com