Hydration induction pretreatment and judgment method before fracturing of shale reservoir

A shale reservoir and pretreatment technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as undiscovered fracture network, and the complexity of fracturing fracture network cannot fully meet production needs, etc. Achieve the effects of maximizing single well production, improving network complexity, and strong field operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

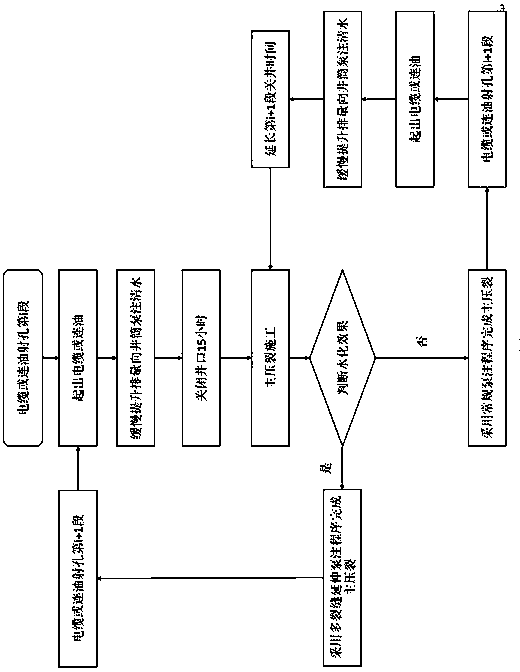

[0028] The invention discloses an on-site construction process of hydration induction pretreatment before fracturing of shale reservoirs. figure 1 As shown, the method includes the following steps:

[0029] (1) Use cable or coiled tubing to perforate the i-section of the reservoir;

[0030] (2) Take out the cable or coiled tubing;

[0031] (3) Slowly increase the displacement and pump clean water into the wellbore for trial extrusion to ensure that the pumping pressure is lower than the safety pressure of the equipment and no large-scale fractures occur in the reservoir, and the maximum displacement does not exceed 5m 3 / min;

[0032] (4) Continuously pump a certain volume of clean water into the wellbore;

[0033] (5) Shut down the well after the clean water pumping is completed, and the shut-in time is longer than 15 hours;

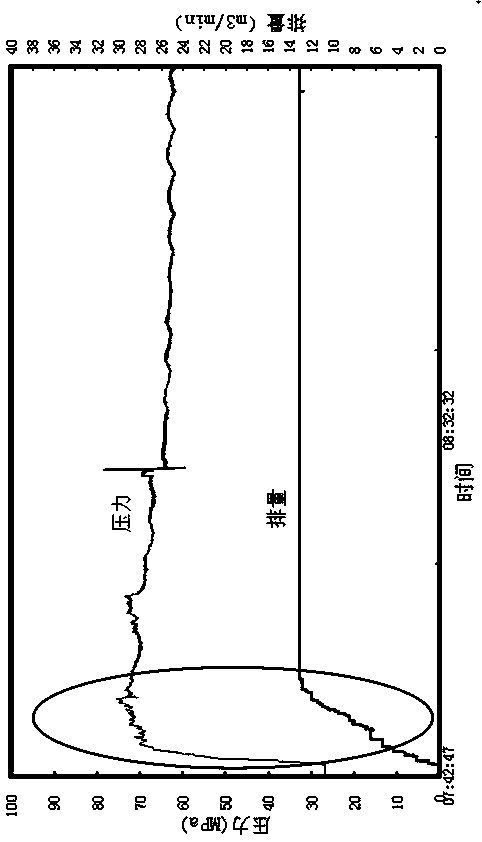

[0034] (6) During the process of main fracturing to increase displacement, if there are multiple sudden drop points or pressure fluctuation zones i...

Embodiment 2

[0041] As the best implementation mode of the present invention, its steps are as follows:

[0042] (1) Carry the perforating gun through the cable or coiled tubing to complete the perforation of the target layer, and then pull out the cable or coiled tubing to avoid downhole complex situations such as perforating gun falling off or coiled tubing deformation.

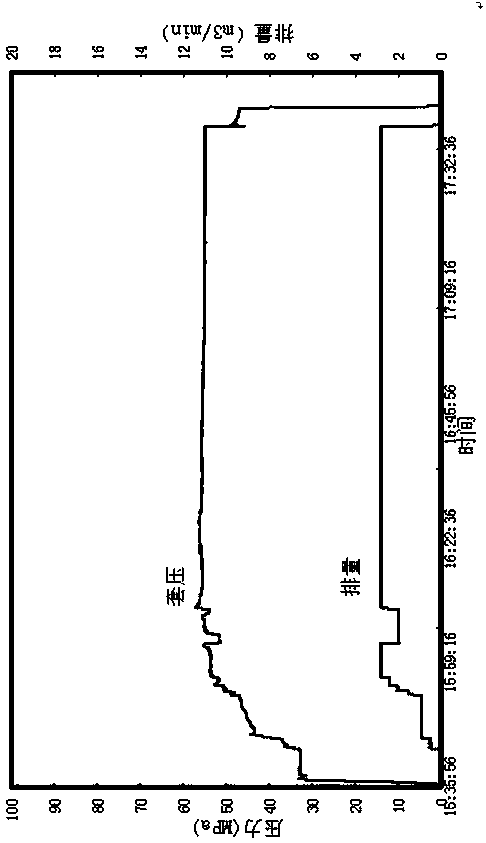

[0043] (2) The initial displacement when pumping clean water is 0.5m 3 / min, observe the pressure change, gradually increase the displacement to 3m after the pressure is stable 3 / min, the rate of displacement does not exceed 0.25m 3 / min / min; if the construction pressure is low, the maximum displacement can be increased to 5m 3 / min, and ensure that the entire pumping process does not cause large-scale fractures in the reservoir. (attached figure 2 )

[0044] (3) The total volume of clean water pumped into the wellbore should be greater than 20% of the liquid volume in the design of the main fracturing scheme to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com