Piston compressor safety protection device

A technology for a safety protection device and a compressor, applied in the field of compressors, can solve problems such as failure to prevent damage to the compressor, and achieve the effects of avoiding equipment loss, having a practical and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

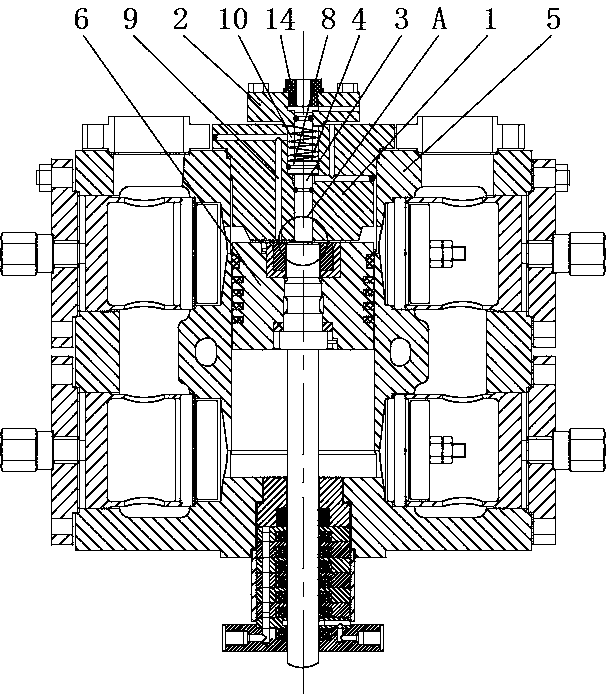

[0034] Such as Figures 1 to 5 As shown, a safety protection device for a piston compressor includes an installation body 1, a press-fit body 2, a contact push rod 3, an elastic element 4 and a trigger mechanism (not shown in the figure);

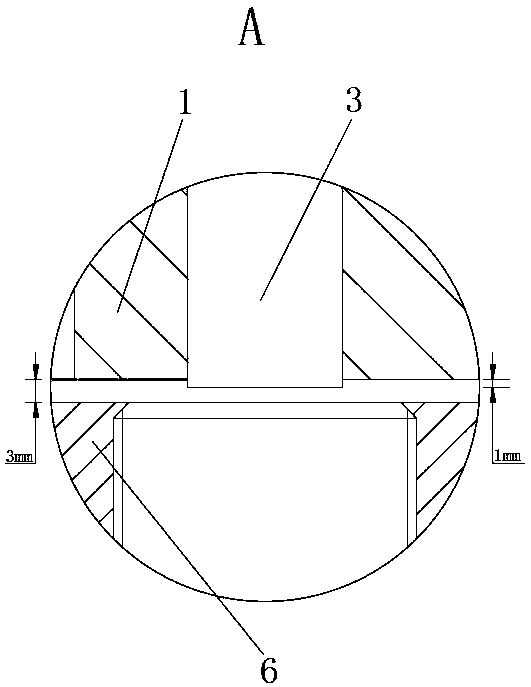

[0035]The installation body 1 is sealed and fixedly installed on the compressor body 5 at the position facing the end of the piston cylinder, and extends into the piston cylinder. The installation body 1 is provided with a step hole 7, and the push rod 3 has a step portion 8. The touch push rod 3 is installed in the step hole 7, and the outer opening of the step hole 7 is sealed and fixedly installed with the press-fit body 2, and the press-fit body 2 is provided with a through hole corresponding to the outer end of the touch push rod 3, and the outside The end is located in the through hole, and the trigger mechanism is installed directly above the outer end surface of the push rod 3. The trigger mechanism is connected to the automatic shu...

Embodiment 2

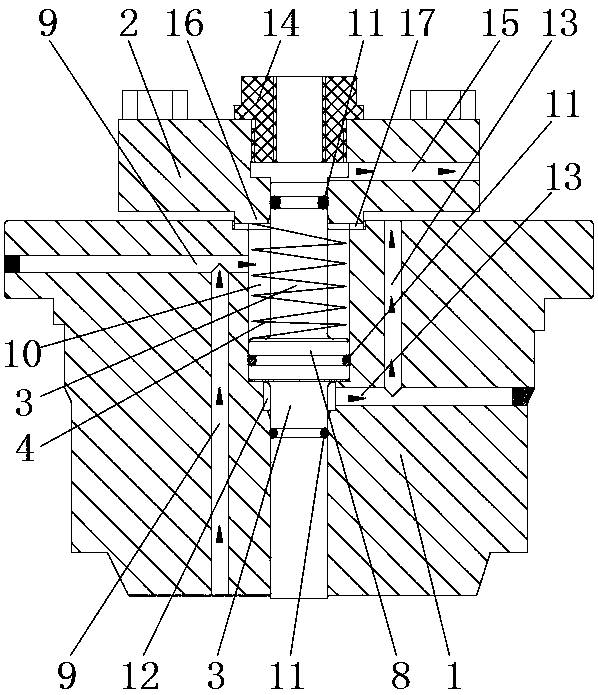

[0041] Such as Figures 1 to 5 As shown, on the basis of Embodiment 1, a pressure relief groove is provided on the inner wall of the step hole 7, and a pressure relief chamber 12 is formed between the pressure relief groove and the outer wall of the contact push rod 3, and the pressure relief groove is located between the step portion 8 and the mounting body. Between the inner end faces of 1, a first pressure relief hole 13 is opened on the installation body 1, and the first pressure relief hole 13 communicates the pressure relief chamber 12 with the outside world, so that the medium leaking through the piston cylinder and the closed cavity 10 leak out The medium in the pressure relief chamber 12 can be discharged to the atmosphere through the first pressure relief hole 13 to prevent the pressure in the pressure relief chamber 12 from being too high, which will cause the pressure of the medium in the pressure relief chamber 12 to cause excessive force on the step portion 8 in t...

Embodiment 3

[0044] Such as Figures 6 to 11 As shown, on the basis of Embodiment 2, two sets of safety protection devices are installed on the piston compressor body 5. At the same time, different from Embodiments 1 and 2, these two sets of safety protection devices are specifically installed on the horizontal piston On the type compressor, two sets of safety protection devices are installed on the body 5 through the hollow cylinder head 18, and the touch and push rods 3 of the two sets of safety protection devices are symmetrical with respect to the center line of the piston cylinder, and the respective touch and push rods of the two sets of protection devices The difference between the inner end surface of the rod 3 and the inner end surface of the corresponding installation body 1 is 0.5mm, and the safety protection device with a larger distance between the inner end surface of the push rod 3 and the inner end surface of the installation body 1 The trigger mechanism is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com