Mounting method of water injection and natural pipe sinking river-crossing pipeline

An installation method and pipeline technology, which can be used in pipeline laying and maintenance, pipe/pipe joints/pipe fittings, water resource protection, etc. Ensure the installation quality, ensure the accuracy, and the effect of accurate elevation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

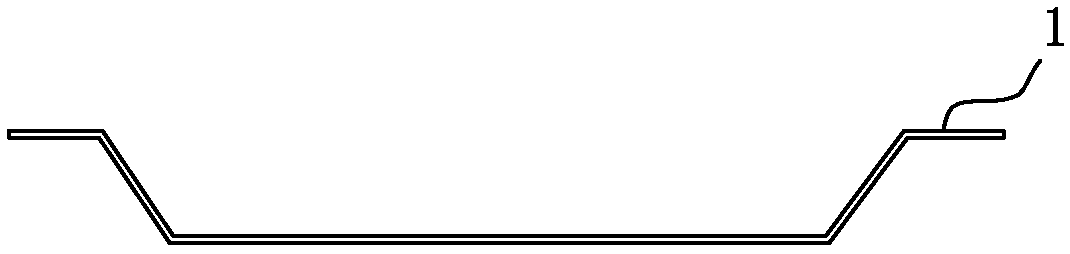

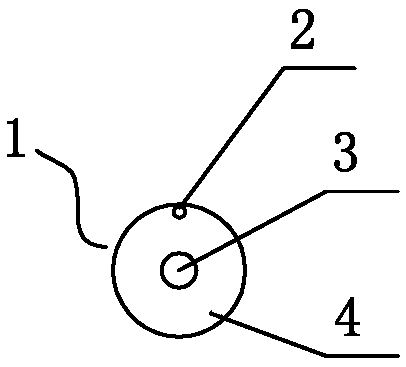

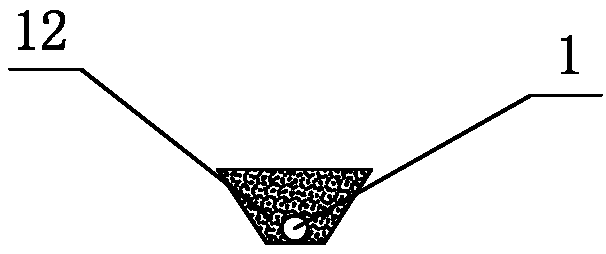

[0055] A method for installing water-injected naturally immersed pipes crossing the river. The installation method is to install water inlets, exhaust ports, openable valves and other devices at both ends of the river-crossing pipelines to cooperate with each other to complete the water injection in the pipe, and control the water injection volume manually. Control the sum of the weight of the water injection and the pipeline to be equal to the buoyancy it receives, so that the pipeline naturally sinks to realize the installation of the pipeline with a large height difference across the river. The upward buoyant force is equal to the weight of the fluid displaced by the object. When the weight of the pipeline and the water injection is equal to the buoyancy, the sinking of the pipeline is negligible due to the influence of the water flow velocity. The positioning of the pipeline is completed by hoisting machine and manual cooperation, and steel pipe scaffolding is used at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com