Integrated type low-nitrogen efficient fuel gas heating station

A heating station and gas technology, which is applied in the field of self-contained low-nitrogen and high-efficiency gas heating stations, can solve the problems of long installation period, inconvenient movement, and inflexible expansion of equipment, so as to improve the heat utilization rate and facilitate mobile use. , apply flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

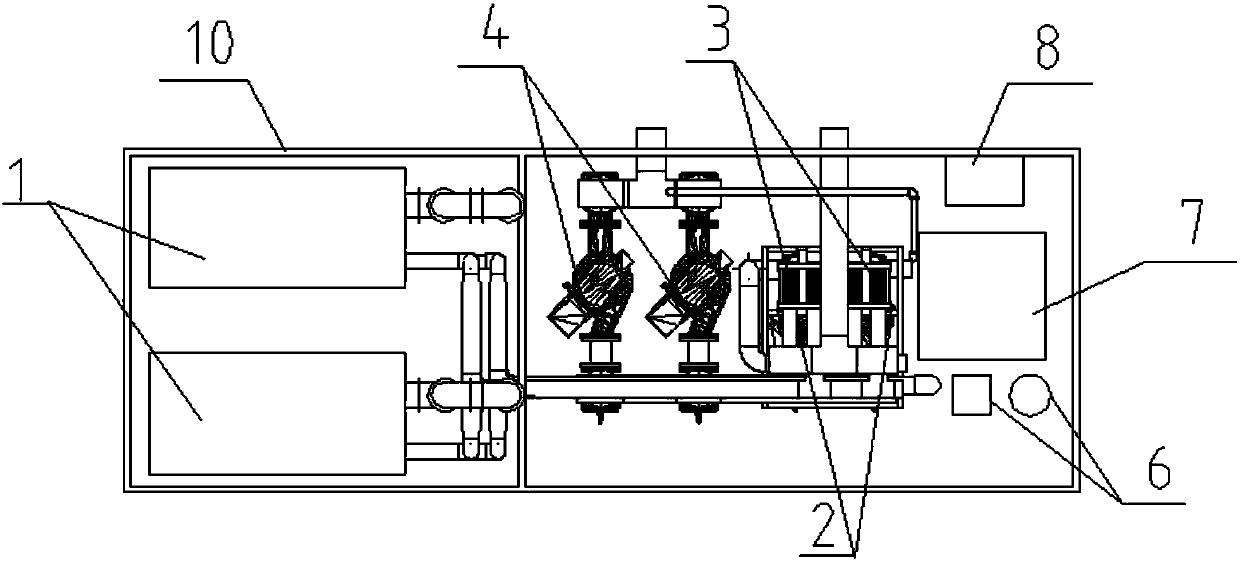

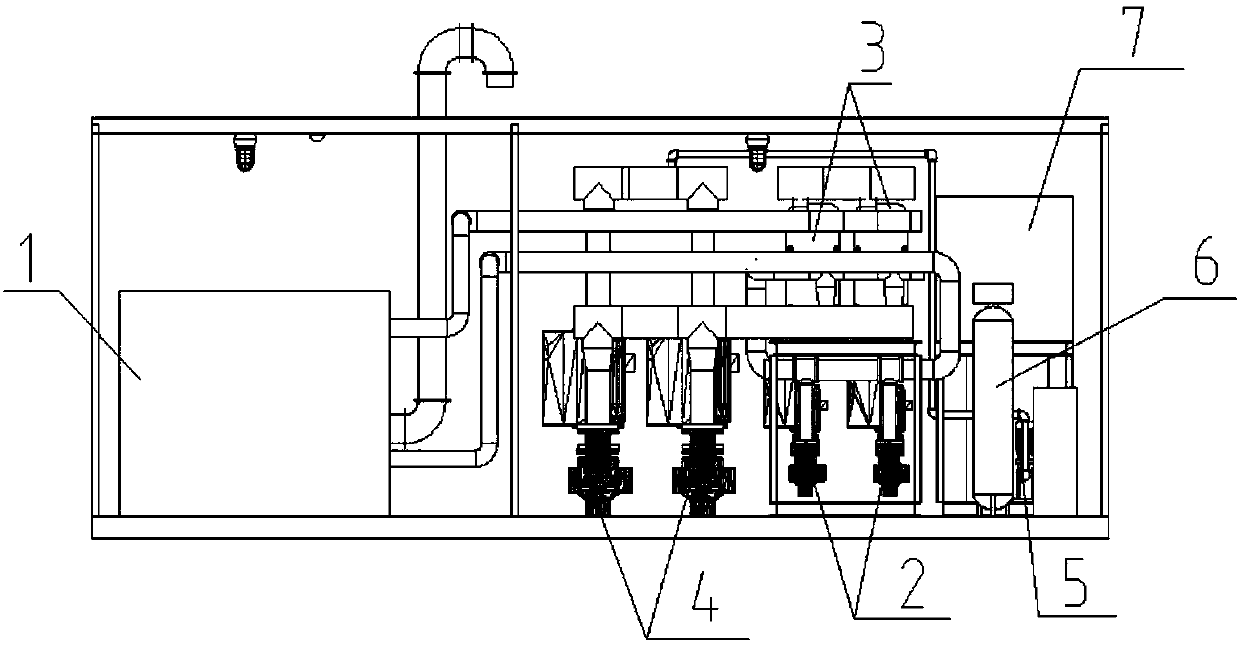

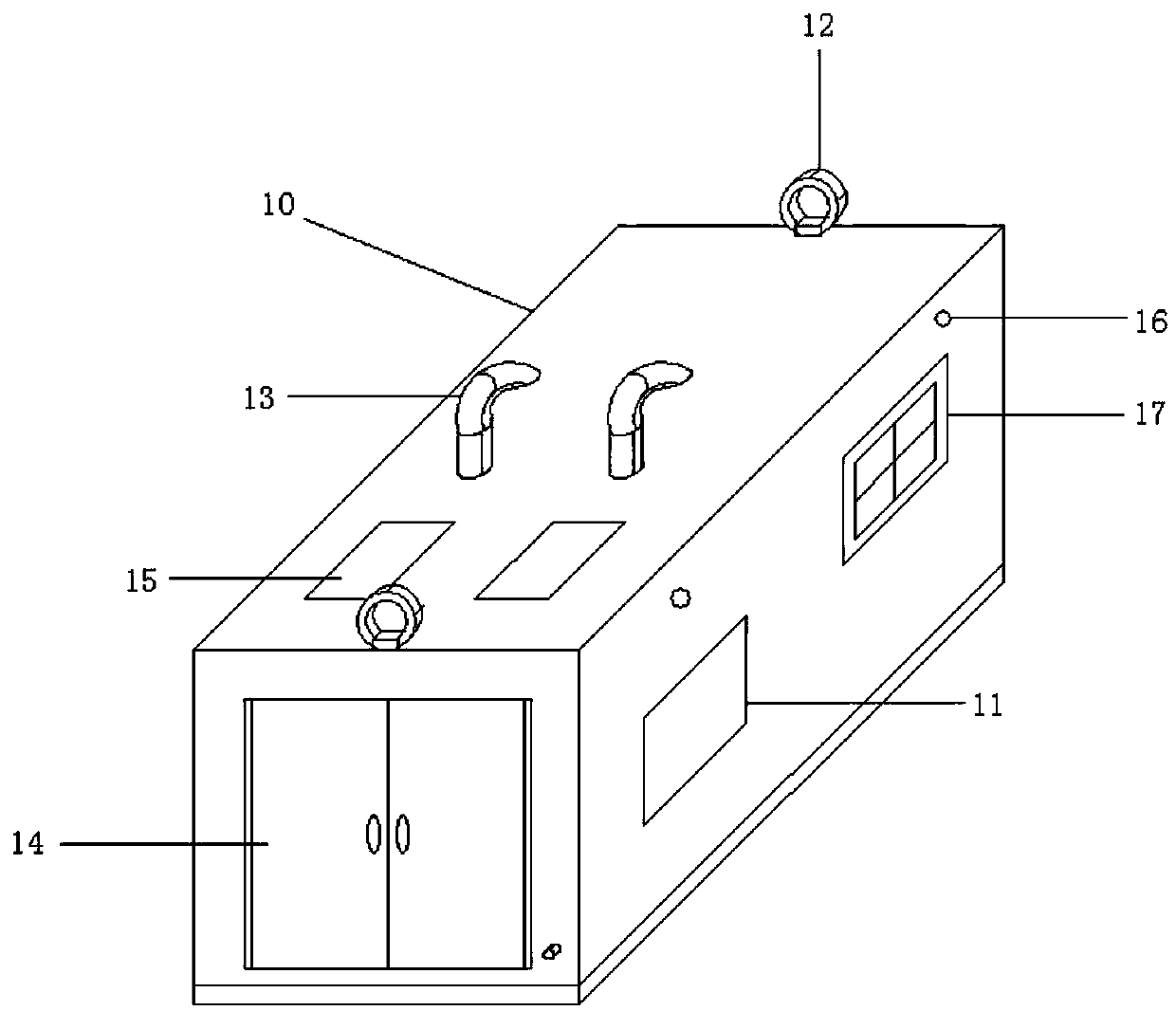

[0017] Such as Figure 1-2 As shown, a self-contained low-nitrogen high-efficiency gas heating station designed by the present invention, each functional module of the heating station is fully assembled in the container body 10, and two gas-fired boilers are arranged side by side on the leftmost side of the container body 10 1. The gas-fired boiler 1 is a low-nitrogen and high-efficiency gas-fired boiler. Two secondary-side circulating water pumps 4 are arranged side by side on the right side of the gas-fired boiler 1 . Two primary side circulating water pumps 2 and a plate heat exchanger 3 are arranged on the right side of the secondary side circulating water pump 4. The primary side circulating water pump 2 is connected to the gas boiler 1 through pipelines. The secondary side circulating water pump 4 and the primary side circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com