Three-dimensional detection device and method for scanning appearance of a welding seam in high-frequency resistance welding based on linear structured light

A high-frequency resistance welding and line structured light technology, applied in the field of three-dimensional detection, can solve the problem of inability to accurately determine the center position of the laser line, and achieve the effects of high precision, improved measurement accuracy and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

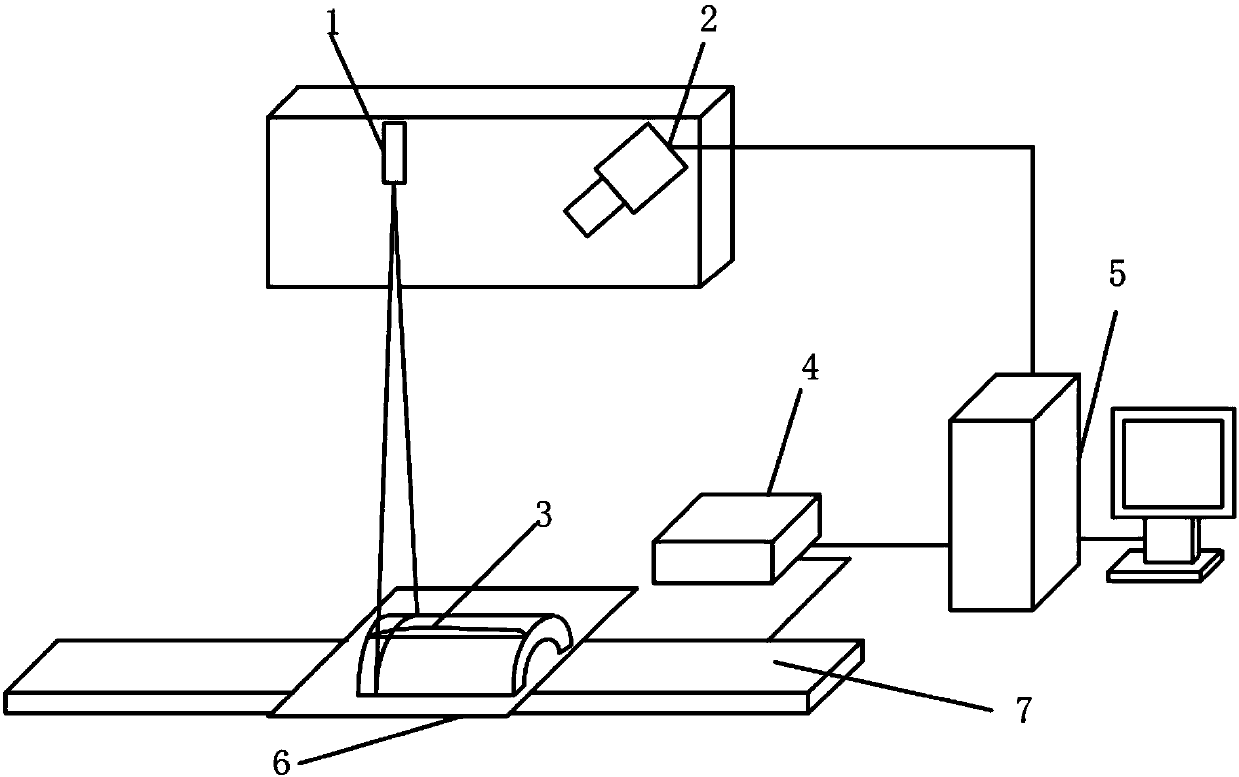

[0030] see figure 1 , the present invention based on line-structured light scanning high-frequency resistance welding welding seam three-dimensional detection device, including 650mm red laser, industrial camera model WAT-902H2, stepper motor controller, computer and base, red laser 1 and the industrial camera 2 are fixed in the same panel to form a line structured light sensor. The industrial camera 2 is inclined downward and forms an angle of 37° with the vertical direction. The base 6 is fixed on the On the mechanical device 7, the mechanical device 7 can make the base 6 move linearly under the drive of the stepping motor, and the object 3 to be welded is fixed on the base 6. The industrial camera 2 and the stepping motor controller 4 are respectively connected with the computer 5, and the stepping The motor is connected with the stepping motor controller 4.

[0031] The above-mentioned device is a non-contact scanning device for obtaining three-dimensional information of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com