Device for error-proof detection of metal insert of plastic product

A metal insert, error-proofing technology, applied in the direction of measuring device, use of re-radiation, re-radiation of sound waves, etc., can solve the problems of customer production quality hidden danger, low inspection efficiency, long time, etc., to prevent leakage of embedded products. , Solve the effect of low efficiency and short inspection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

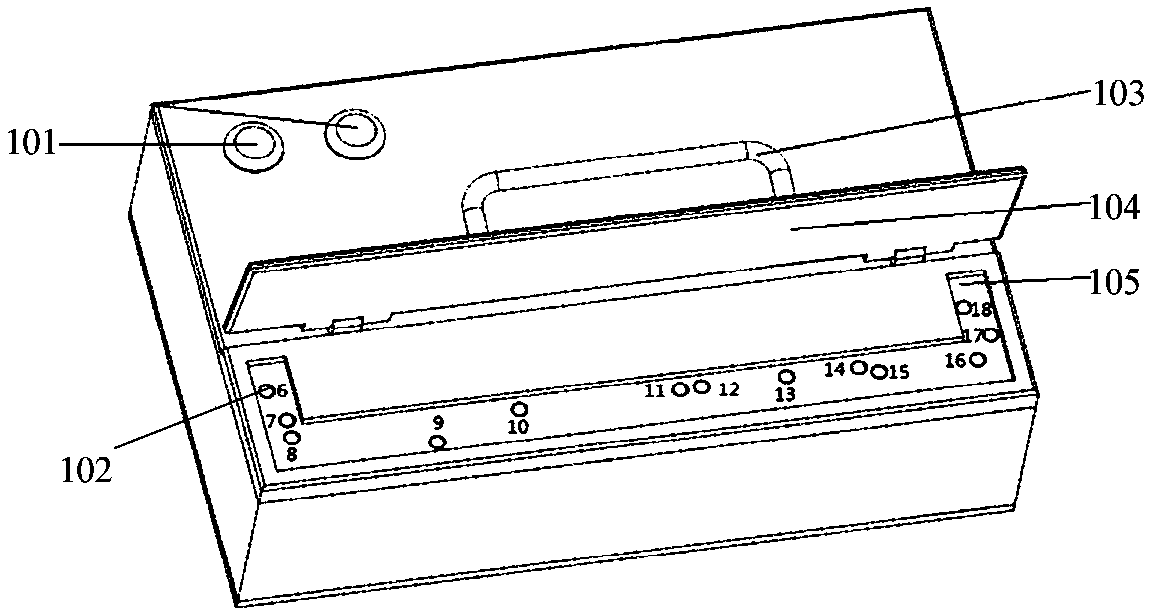

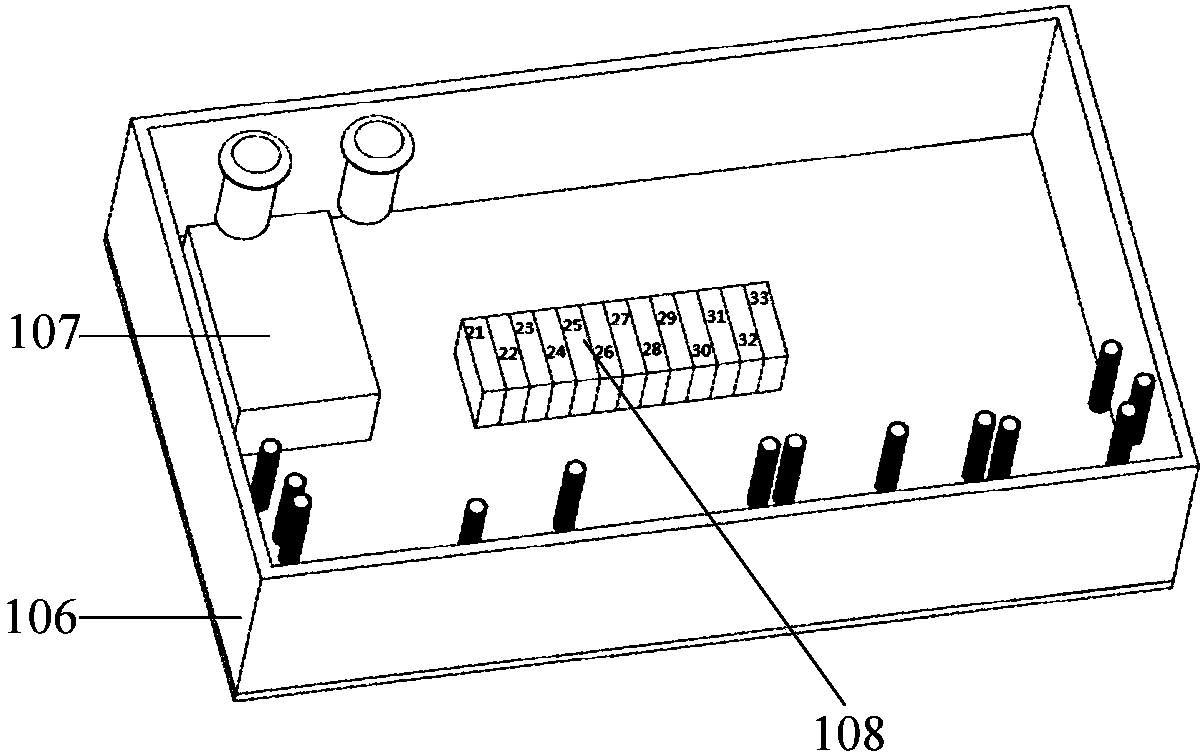

[0018] Such as figure 1 , figure 2 As shown, the equipment for error-proof detection of metal inserts in plastic products includes a box body 106 and a power supply 107 and a relay 108 placed in it. A product pressure plate 104 is hinged on the box body 106. The box body opposite to the product pressure plate There is a product positioning groove 105 for carrying the product to be tested, and a plurality of sensor switches 102 for contacting the insert on the product to be tested are distributed on the product positioning groove 105, and an audible and visual alarm unit 101 is installed on the box body 106 .

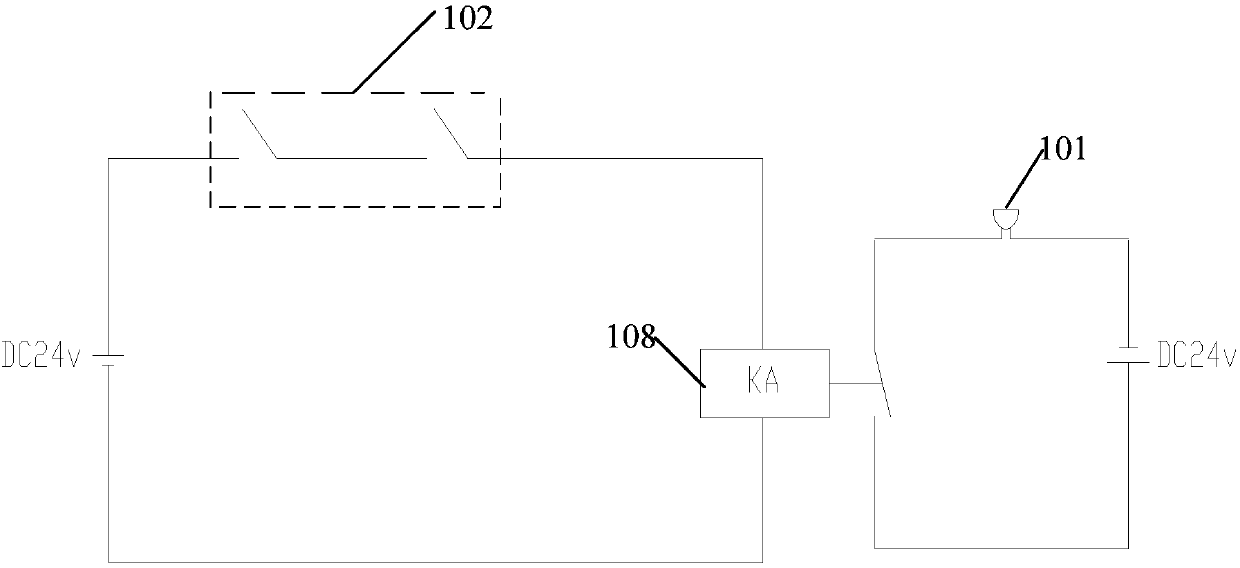

[0019] Such as image 3 As shown, the sensor switch 102 is connected in series with the input circuit and power supply of the relay 108 to form a main circuit circuit, and the sound and light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com