Cold standby system fault behavior modeling method based on SBDD (Shared Binary Decision Diagram) model

A system failure and modeling method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to effectively evaluate cold storage component failures and cross-stage damage accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

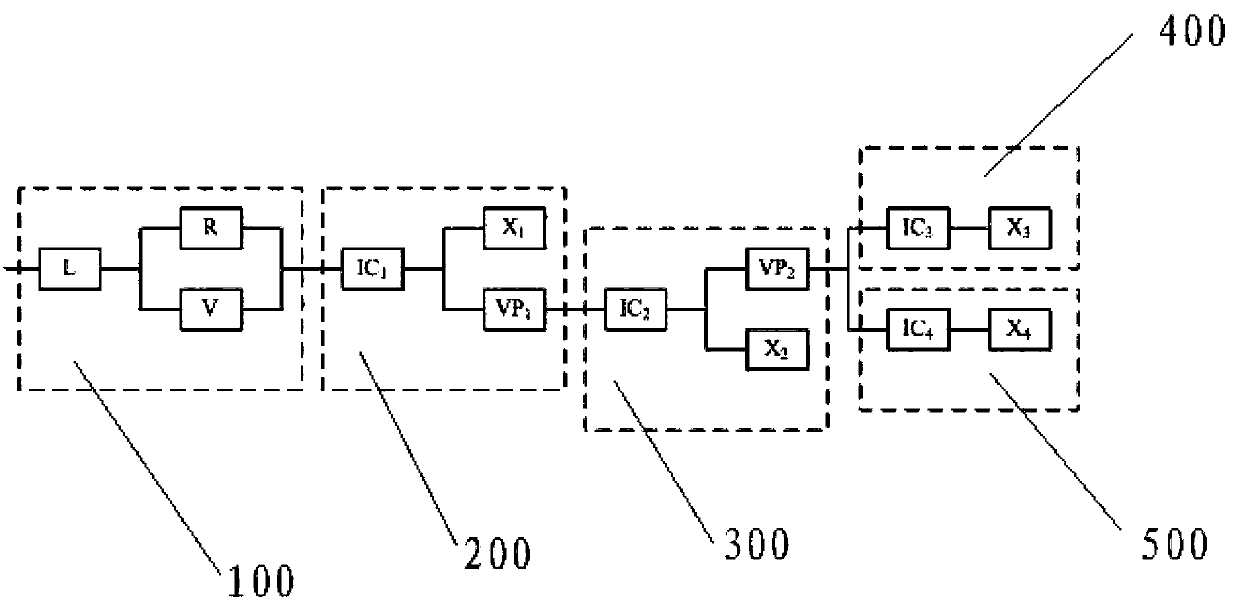

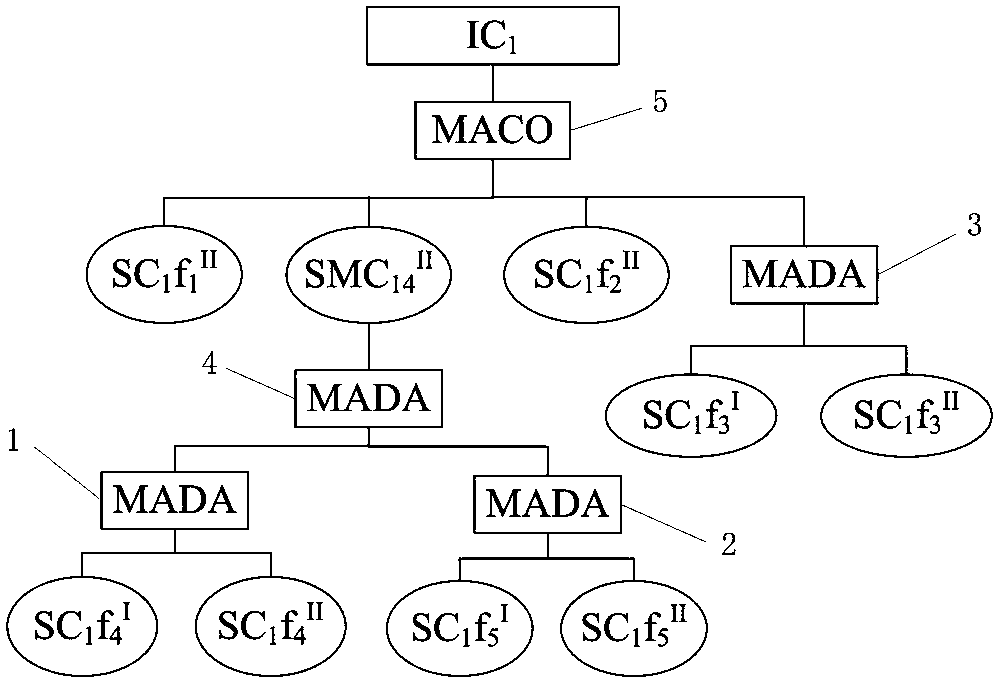

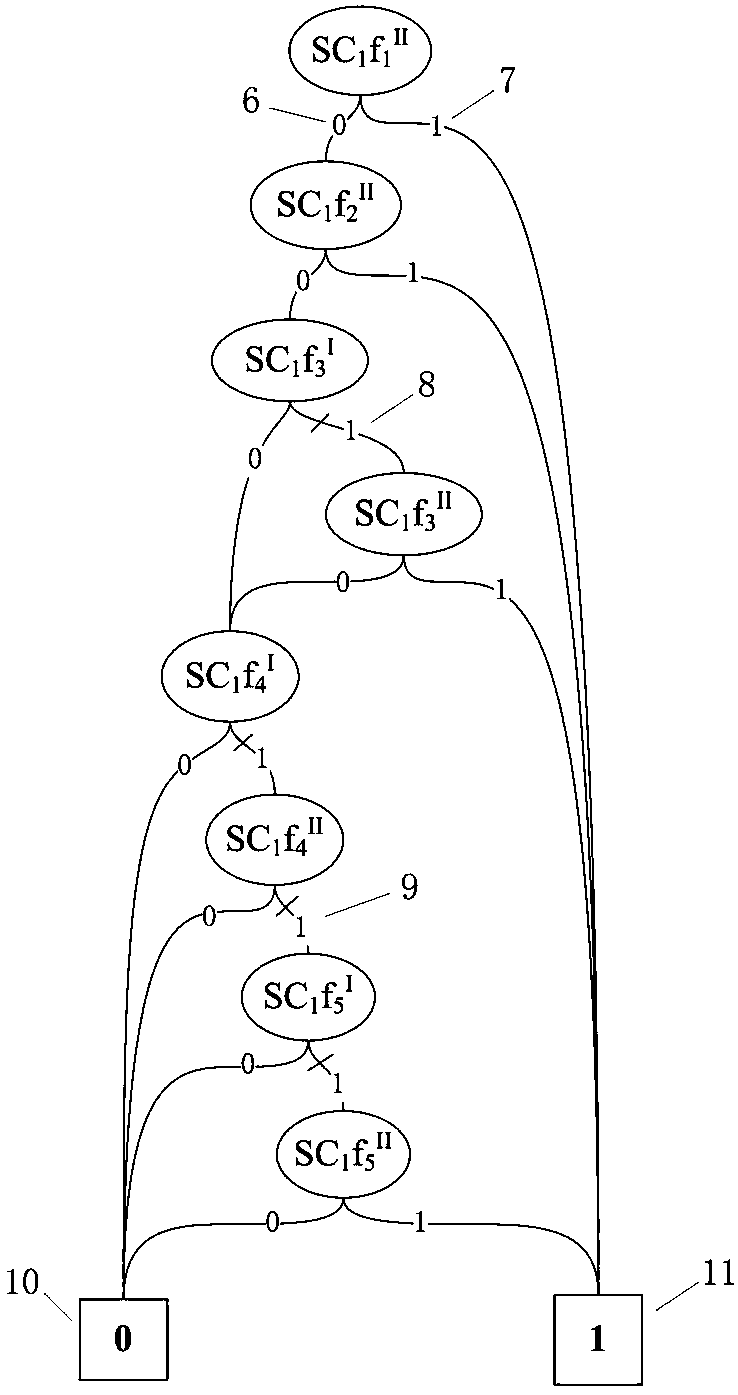

[0057] The following embodiments use the SBDD model (continuous binary decision diagram model) to model the power supply subsystem of an avionics control device and perform MATLAB simulation analysis to reflect the beneficial effects of the present invention.

[0058] The present invention is a cold storage system fault behavior modeling method based on the SBDD model, and the specific implementation steps are as follows:

[0059] Step 1: Analyze and determine the key failure mechanism, failure mechanism type and related relationship of each component of the system.

[0060] The power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com