Automatic overheating cooling system of motor

A cooling system, automatic technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low cooling efficiency and inability to fit the surface of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

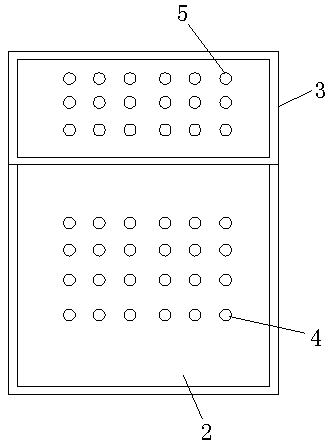

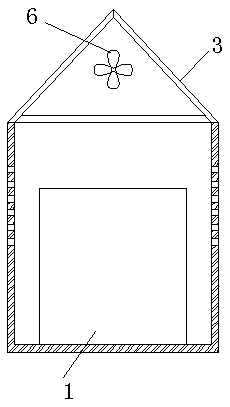

[0017] Such as Figure 1 to Figure 3 As shown, a motor overheating automatic heat dissipation system includes a motor body 1, an open box body 2 and a triangular prism-shaped box cover 3 for sealing the opening, any two of the box body 2 opposite Each has a plurality of ventilation holes 4 on the side; each of the two rectangular faces of the triangular prism-shaped case cover 3 has a plurality of air outlet holes 5, and the triangular faces on both sides of the triangular prism-shaped case cover 3 are respectively installed There is an exhaust fan6.

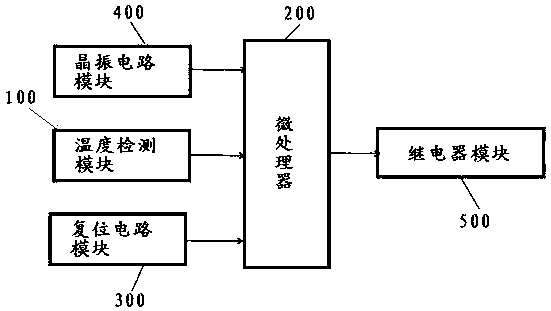

[0018] Also includes an automatic cooling system, which includes a temperature detection module 100, a microprocessor 200, a reset circuit module 300, a crystal oscillator circuit module 400 and a relay module 500; the reset circuit module 400 and the crystal oscillator circuit module 500 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com