Rhombic shaking table top

A rhombus and shape technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problem that the separation effect is difficult to meet the ideal requirements, and achieve the effect of prolonging the separation time and high separation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

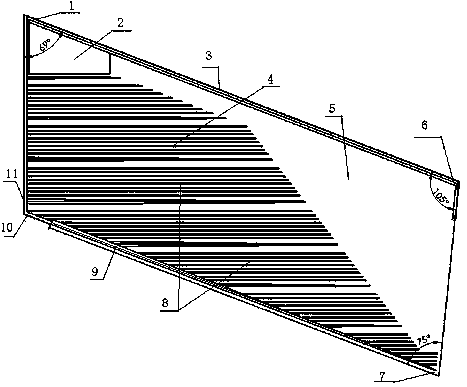

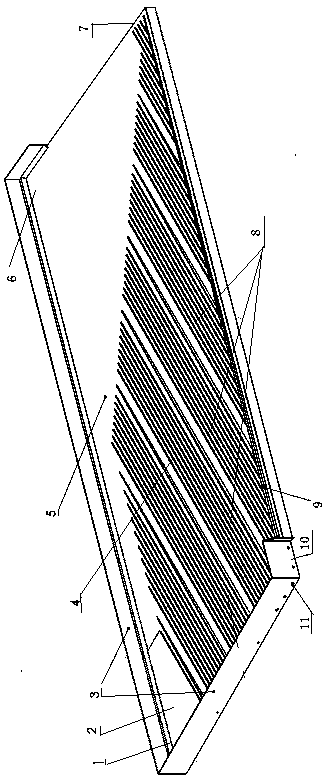

[0012] Diamond shaker bed surface, including bed surface, water blocking plate 3, water blocking plate 3 is installed on the edge of the bed surface, the top view of the shaking table surface is approximately diamond shaped, the bed surface is divided into mining area 2, grooved area 4, no groove Area 5, mining area 2 is located in the upper acute angle area 1, groove area 4 is located on the side of the lower obtuse angle area 10, groove area 4 is adjacent to the mining area 2, groove area 4 is provided with groove 8 and interception groove 9. The interception groove 9 is arranged parallel to the shared sideline of the lower obtuse angle 10 and the lower acute angle 7, and the carving groove 8 is set between the mining area 2 and the interception groove 9, and the direction of the groove 8 is perpendicular to the shared sideline of the lower obtuse angle 10 and the upper acute angle 1, without The grooved area 5 is arranged on the upper adjacent area and the upper obtuse angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com