Trough body for high-efficiency permanent magnet drum magnetic separator

A permanent magnet drum type, magnetic separator technology, applied in solid separation, magnetic separation, chemical instruments and methods, etc., can solve the problems of increasing the residence time of ore pulp, etc., to extend the separation time, overflow weir height, and sorting with long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

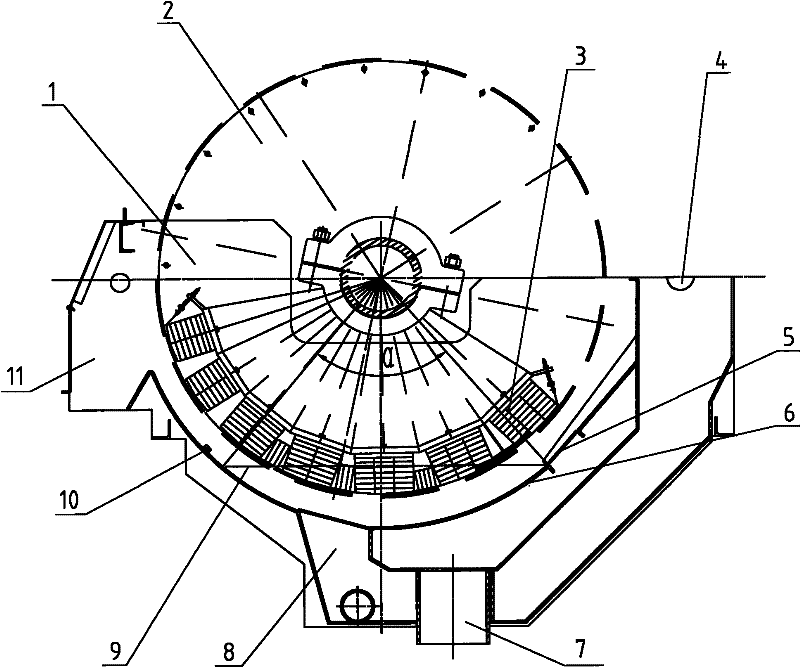

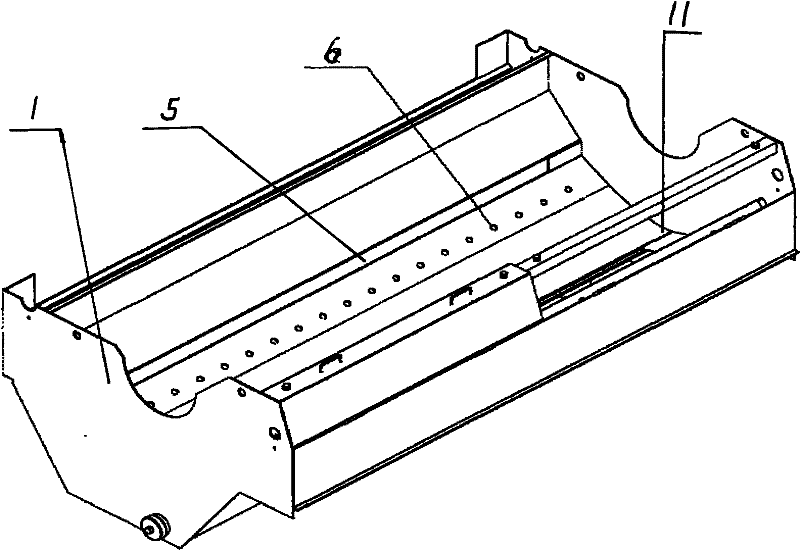

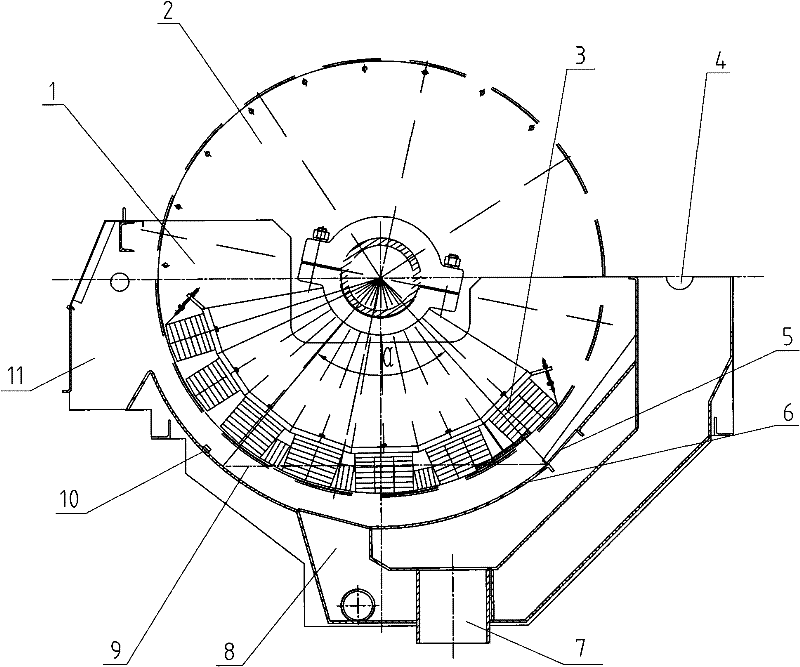

[0016] by Figure 1-2 As shown, 1 in the figure is a tank body 1 that is provided with a mine inlet 4 on the upper side and a tailings outlet 7 at the bottom and corresponding to the high-efficiency permanent magnet cylinder 2. The tank body 1 is welded by austenitic non-magnetic stainless steel The bottom surface of the tank body is provided with a mine inlet 8 connected to the ore inlet 4, and on the slope of the tank body on the same side as the ore inlet, there is an overflow connected with the tailings outlet. The outflow port 5 is provided with a coarse particle discharge hole 6 connected to the tailing outlet 7 in the tank body at the lower part of the overflow port; a concentrate outlet 11 is also provided on the upper part of the tank slope on the side opposite to the feeding inlet. In addition, 3 in the figure is the magnetic system in the permanent magnet cylinder.

[0017] The height of the overflow weir ranges from 180mm to 250mm, the magnetic wrap angle of the perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com