Operation method of liquid-solid fluidized bed coarse slime separation device with adjustable water velocity in height direction

A technology of height direction and separation device, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of high ash fine mud pollution to clean coal, affecting separation effect, etc., and prolong separation time. , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

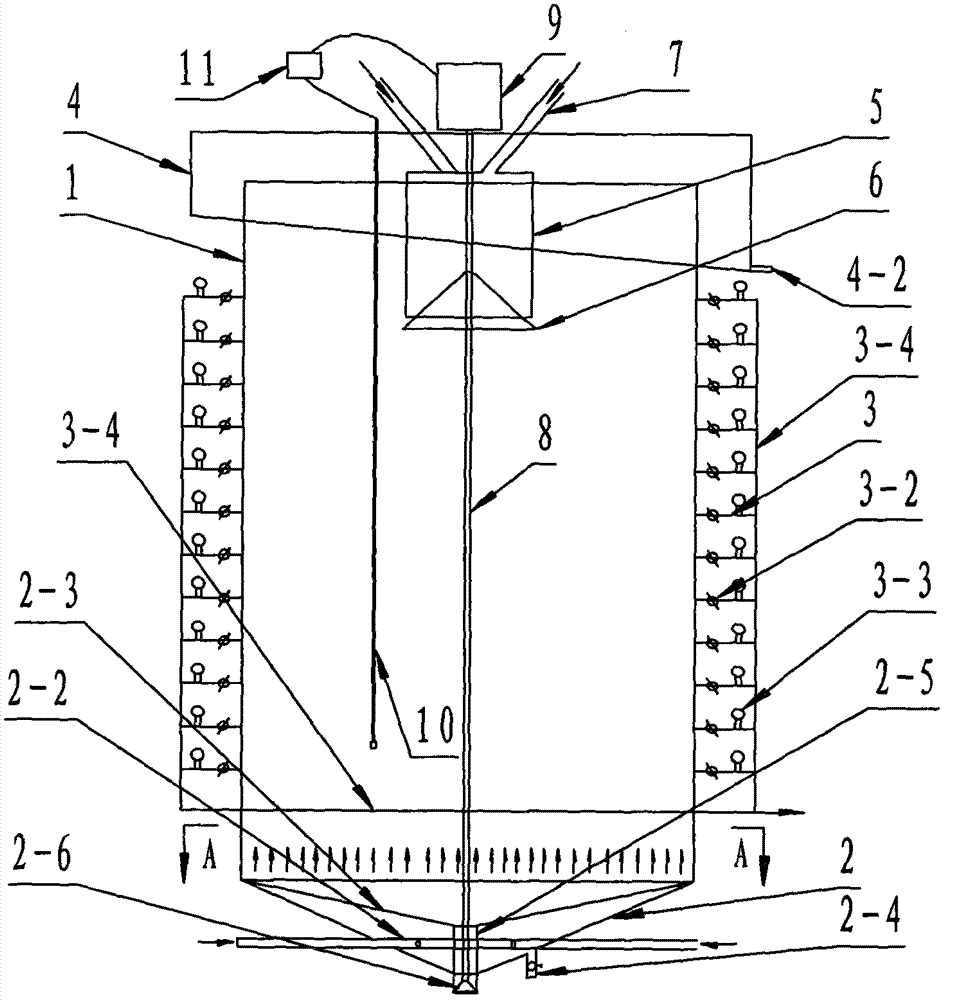

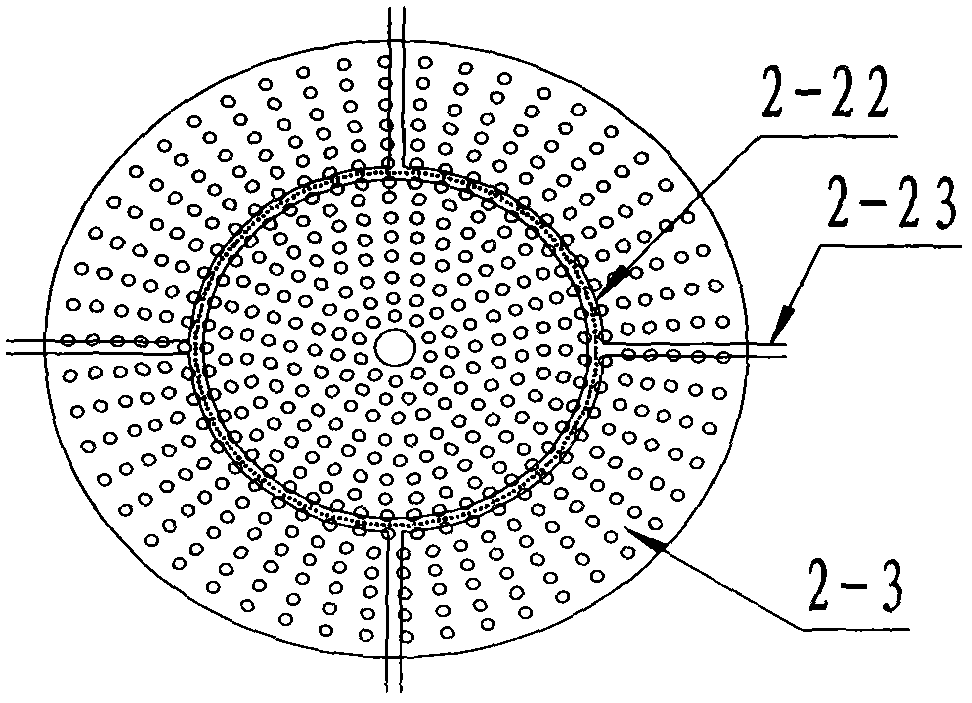

[0022]The outer wall of the fluidized bed cylinder 1 is provided with at least five sets of water discharge pipes 3 from top to bottom, and the conical water filling tank 2 is arranged under the fluidized bed cylinder 1, and the discharge valve 2-4 is arranged on one side of the outer wall of the water filling tank 2, and the water filling tank 2 The water distribution pipe 2-2 is arranged inside, and the trumpet-shaped sieve plate type fluid distributor 2-3 is arranged above the water distribution pipe 2-2; the feeding well 5 is arranged in the center above the fluidized bed cylinder 1, and the conical spreading material is arranged below the feeding well 5 A pair of feeding pipes 7 are arranged symmetrically on both sides of the disk 6 and the upper side of the feeding shaft 5. The overflow port of the fluidized bed cylinder 1 is equipped with an overflow concentrate collection mechanism 4 inclined at the bottom. The overflow concentrate collection mechanism 4 The concentrate...

Embodiment 2

[0028] The coarse coal slime classified in the previous process of the coal washing plant enters the feeding well 5 through the feeding pipe 7. The particle size of the coarse coal slime particles meets the effective particle size range of fluidized bed separation, and the coarse coal slime passes through the spreading plate 6. Evenly enter the fluidized bed cylinder 1, and at the same time, the frequency converter controls the pump to control the water speed entering the water inlet pipe 2-23. The water speed is a fixed value. After entering the water inlet pipe 2-23, the water passes through the annular water pipe 2-22 The hole on the upper surface enters the water-filled tank 2, and then enters the fluidized bed cylinder 1 through the fluid distributor 2-3 to form a stable upward water flow. The coarse coal slime particles in the fluidized bed cylinder 1 are mixed with water, due to the free settlement of the particles The speed is relatively large, and the coarse coal slime...

Embodiment 3

[0030] The water discharge valve 3-2 of the water discharge pipeline 3 is opened, and the high ash fine mud that is less than the effective particle size range value of the coarse coal slime particle fluidized bed sorting enters the water discharge pipeline 3 through the screen of the water inlet along the water flow, and the sieve The diameter of the net is 0.25mm, and the flow sensor 3-3 shows the amount of water flowing out, which is discharged through the water discharge main pipe 3-4. Due to the reduction of the water amount in the fluidized bed cylinder 1, the coarse coal slime particles in the fluidized bed cylinder 1 The concentration gradually increases from top to bottom along the height of the fluidized bed, the equal sedimentation ratio between particles increases, and the separation of coarse coal slime particles according to density is strengthened; the water discharge valve 3-2 of the water discharge pipe 3 is fine-tuned to control the water discharge and adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com