Electric washing device of temperature controller

A technology of temperature controller and ammeter, which is applied in the direction of chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of negative impact of contact resistance, loss of electric energy, impact on life, etc., to overcome large contact resistance, reduce contact resistance, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

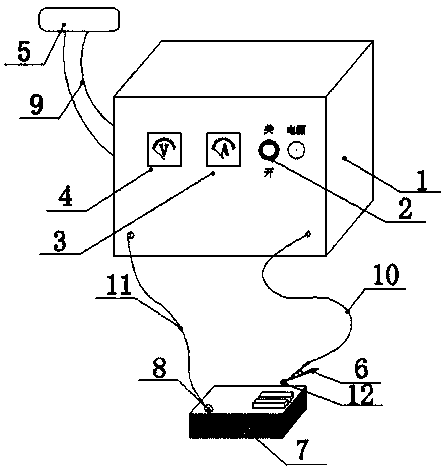

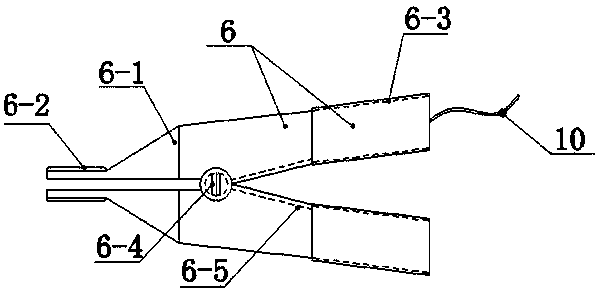

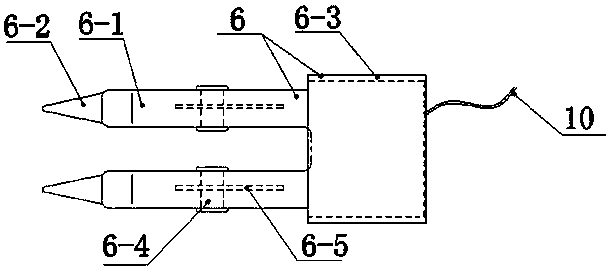

[0013] Embodiment, with reference to accompanying drawing, a kind of electric cleaning device of temperature controller, comprises DC power supply cabinet 1, and power switch 2, ammeter 3, voltmeter 4 are housed on DC power supply cabinet 1, it is characterized in that DC power supply cabinet 1 passes wire One 9 is externally connected to a resistor 5, the wire two 10 is connected to a clip 6 for clamping the product, and the wire three 11 is connected to the start switch 8 on the bakelite block 7; the clip has two U-shaped metal clip bodies 6-1 with a clip in the middle The shafts 6-4 are movably connected together, and a spring 6-5 is installed on the clamp shaft 6-4; an insulating shell 6-3 is installed at the right end handle of the metal clamp body 6-1, and an insulating glue is installed on the upper and lower sides of the clamp product at the left end. Layer 6-2.

[0014] The working principle and method of use of this invention are: turn on the power switch 2 to open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com