Single-end cutting saw capable of conducting continuous cutting

A technology for cutting saws and saw blades, which is applied in the field of equipment for the manufacture of aluminum alloy doors and windows. It can solve problems such as easy wear, long processing time, and easy overheating of saw blades, and achieve the effects of improving work efficiency, improving production efficiency, and saving total time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

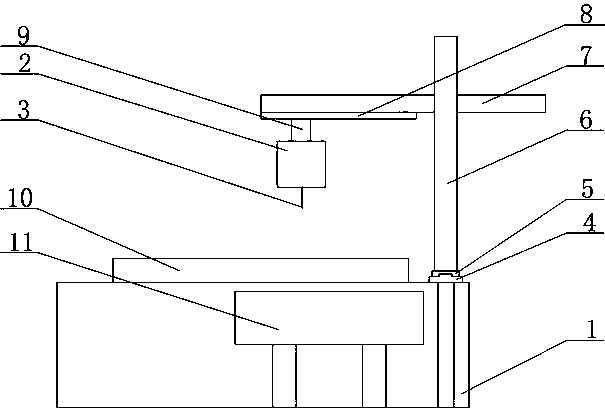

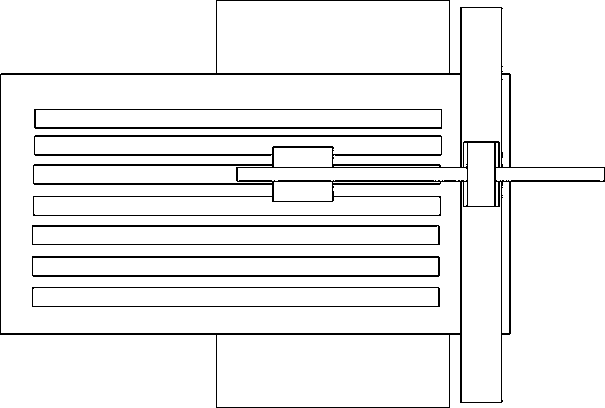

[0021] Such as figure 1 and figure 2 As shown, a single-head cutting saw capable of continuous cutting includes a workbench 1, a motor box 2 and a saw blade 3, and the saw blade 3 is installed on the motor box 2. It is characterized in that the top of the workbench 1 A first guide rail 4 is installed on one side, and a water tank 11 is arranged on the outside of the workbench 1 and in a direction perpendicular to the first guide rail 4. The first guide rail 4 extends a certain distance to the outside of the workbench 1, and the first guide rail 4 extends out A support bar is provided under the part of the workbench 1, and a first slide block 5 matching it is provided on the first guide rail 4, and a longitudinal support bar 6 is fixed above the first slide block 5, and in the longitudinal support bar 6 A hydraulic machine is provided, and a lifting rod is connected to the hydraulic machine, and a horizontal support rod 7 is fixed on the upper end of the lifting rod, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com